Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

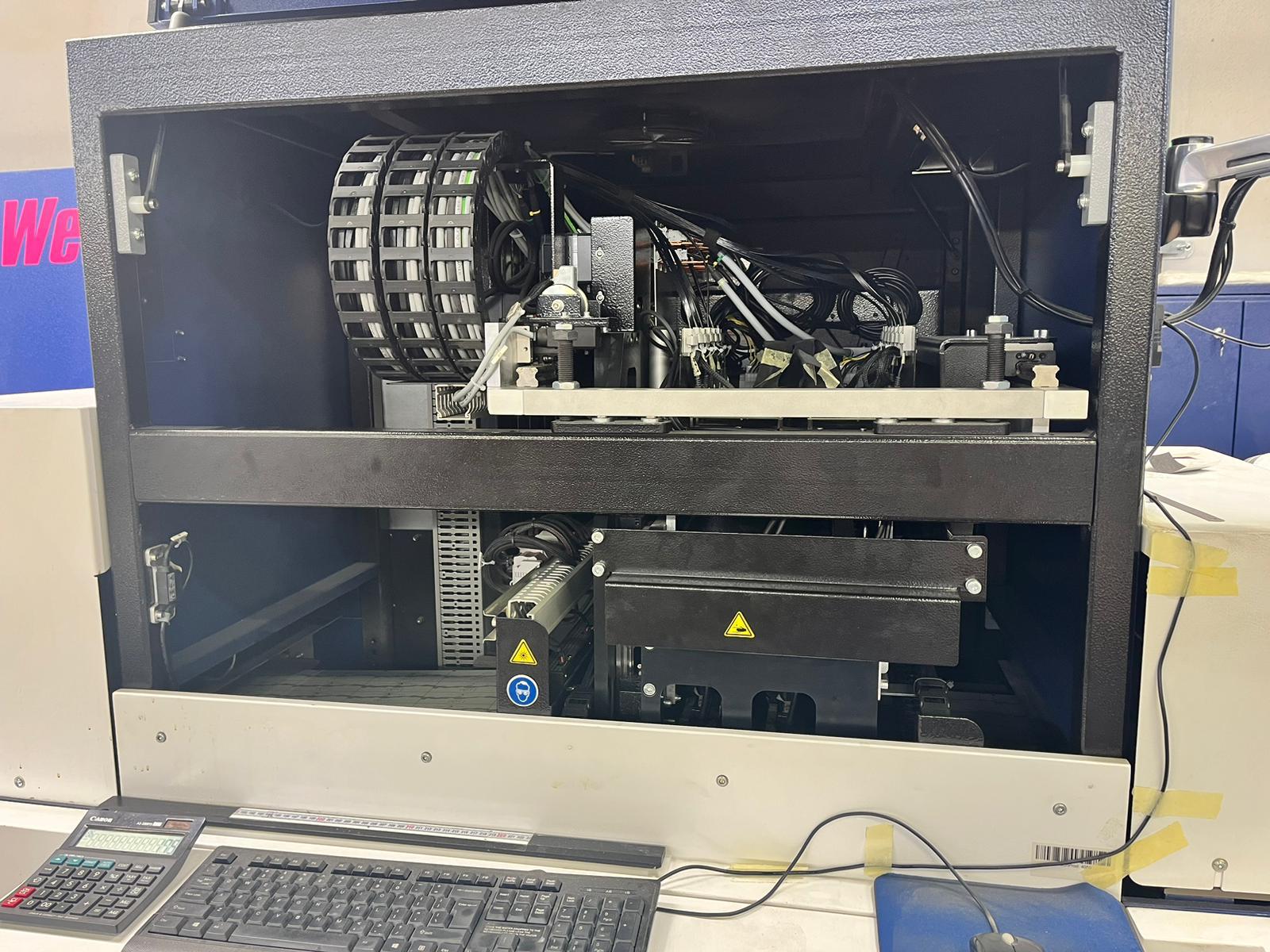

MGI JETvarnish 3D Web

The machine was selected and carefully inspected by our engineers prior to purchase. Subsequently, it underwent a rigorous overhaul process, based on a well-established working protocol. This process involves disassembly in our specialized workshop, thorough cleaning, repainting of components and units, accurate reassembly, and the overhaul or replacement of all non-conforming or damaged parts and mechanisms according to our long and established experience. Each component is adjusted with centesimal precision to ensure compliance with original factory parameters. Finally, the machine is reassembled and subjected to thorough functionality tests and inspections for the best result according to our high quality standards.

MACHINE SPECIFICATION

| Manufacturer | MGI |

|---|---|

| Model | JETvarnish 3D Web |

| Type | Digital Printing |

TECHNICAL DATA

| Max sheet size | 420 |

|---|---|

| Min sheet size | 100 |

Accessories

- Feeder

- Unwinder

- Corona Treatment Vetafone

- Printing Units

- FLEXO head with Anilox 8/12/15 volume (Full size printing)

- UV lamp flexo

- Quality control system

- Double Konica ink jet heads foir Braile

- LED UV BAR

- IR DRYER

- UV LAMP with cooled roller

- Lamination unit with shafts 22/76mm and heated roller

- Delivery

- SEMIROTATIVE DIECUTTING UNIT SMAG 19”

- Gap-master

- Shaft for material waste

- Rewinder

Machine overview

| Year | 2019 |

|---|---|

| Serial Number | JV3DW42-067 |

“EXTRA” Accessories Overview

- Corona Treatment Vetafone

- UV lamp flexo

- Quality control system

- Lamination unit with shafts 22/76mm and heated roller

- SEMIROTATIVE DIECUTTING UNIT SMAG 19”

- Gap-master

Reference Overview

| Reference | 24036427 |

|---|---|

| Visible | In production |

| Availability | Immediately |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset