Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

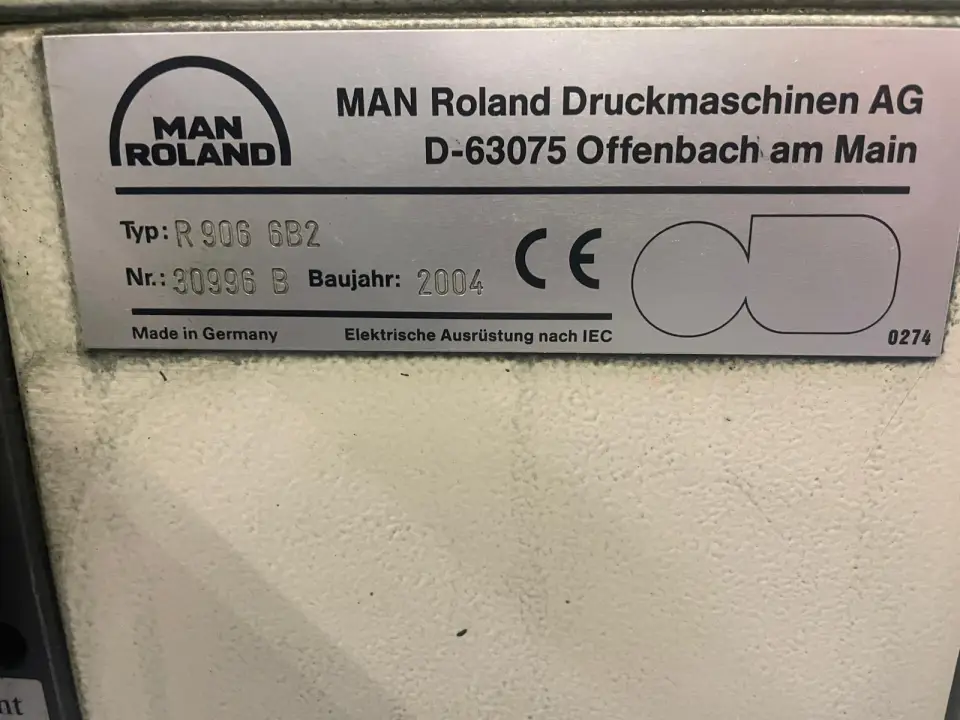

Manroland R 900-6 LTTLV HYBRID (SIZE 6)

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Manroland |

|---|---|

| Model | R 900-6 LTTLV HYBRID (SIZE 6) |

| Type | Sheetfed Offset/Offset a foglio |

TECHNICAL DATA

| Max sheet size | 100 x 140 |

|---|---|

| Min sheet size | 60 x 85 |

| Max print size | 99 x 140 |

| Material Thickness | 0,1 - 1,0 mm ( 90-50 gsm) |

| Plate size | 114 x 141 |

Accessories

- Console

- RCI console for ink and axial, circumferential for plate cylinders

- Multi CCI 2D (Spectrophometric control)

- Feeder

- Pile alignment on feeder

- Pneumatic side lays

- Non-stop on feeder with swords

- Sheet Decurler

- Printing Units

- Automatic roller wash-up device

- Automatic impression cylinder wash-up devices with brush

- Roland-Deltamatic System damping

- TRANSFERTER: Ventury Air Transfer system

- APL : automatic plate change

- Ink Temperature Control KLH type FS60

- Preset automatic sizes adjustment on feeder and delivery, on pressure, on gripper bars transfer cylinder

- Technotrans Beta.d cooling and circulation + automix

- 6th Element with hybrid rollers

- Varnishing units

- Nr 2 Varnishing Towers, the first aqueous the second UV

- Nr 2 Hot Air Drying towers between the two coaters

- Automatic impression cylinder wash-up with brush on coating unit

- Nr 2 varnish pumps ( 1 for conventionale , 1 for UV)

- Delivery

- Non-Stop in delivery

- Grafix Cantronic 3000 powder spray

- Extended delivery

- Eltosch Final Dryer Combination IR/TL (1420): Thermo-air Hot Air and IR Dryer Ir segments, with Exhaust system and Heat Exchanger

- Eltosch UV dryer in delivery with 3 lamps

- Dryer Eltosch IRx8 lamps (4 slides), HOT air knives dryers

- Various

- 13.000 speed/h

- Elevated about 550 mm

Machine overview

| Year | 2004 |

|---|---|

| Serial Number | 30996 B |

| N.of Impressions | 400 mio. |

“EXTRA” Accessories Overview

- Multi CCI 2D (Spectrophometric control)

- Non-stop on feeder with swords

- Sheet Decurler

- APL : automatic plate change

- Ink Temperature Control KLH type FS60

- 6th Element with hybrid rollers

- Nr 2 Varnishing Towers, the first aqueous the second UV

- Nr 2 Hot Air Drying towers between the two coaters

- Nr 2 varnish pumps ( 1 for conventionale , 1 for UV)

- Non-Stop in delivery

- Eltosch UV dryer in delivery with 3 lamps

- Dryer Eltosch IRx8 lamps (4 slides), HOT air knives dryers

- Elevated about 550 mm

Reference Overview

| Reference | 24036471 |

|---|---|

| Visible | In production |

| Availability | Immediately |

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset