Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

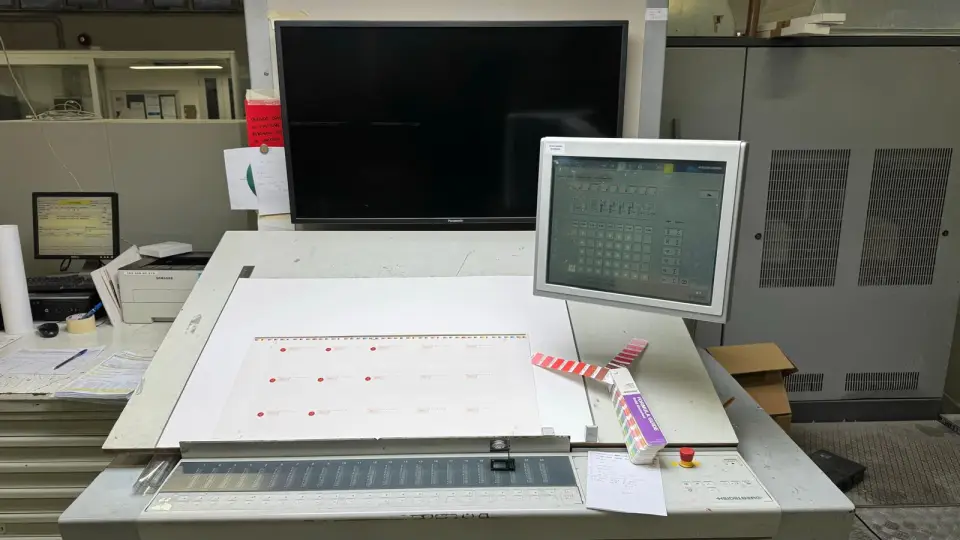

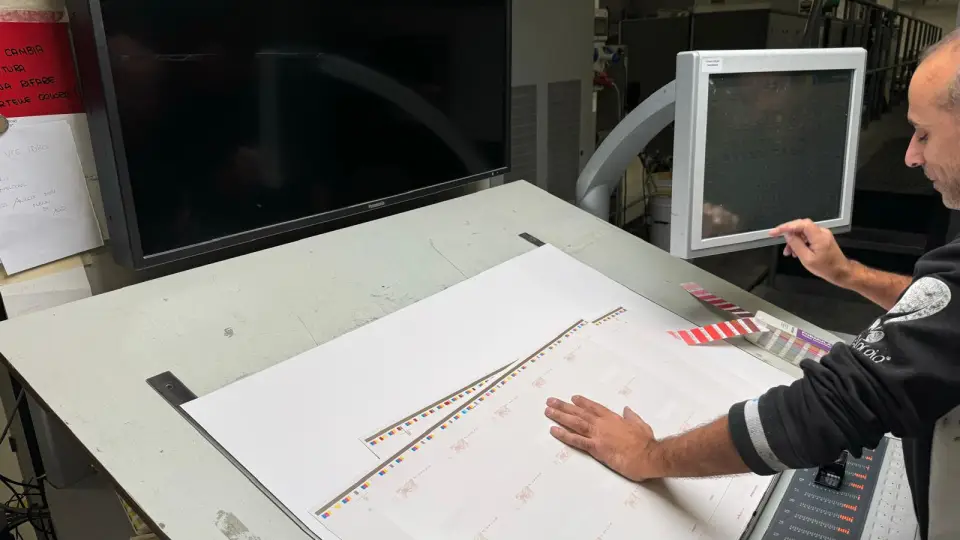

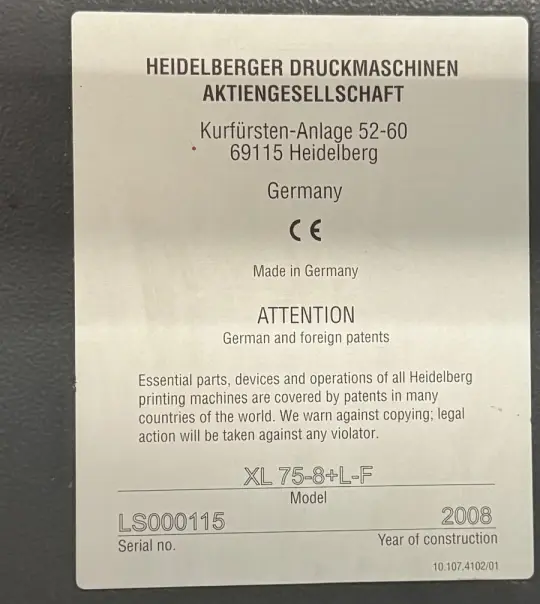

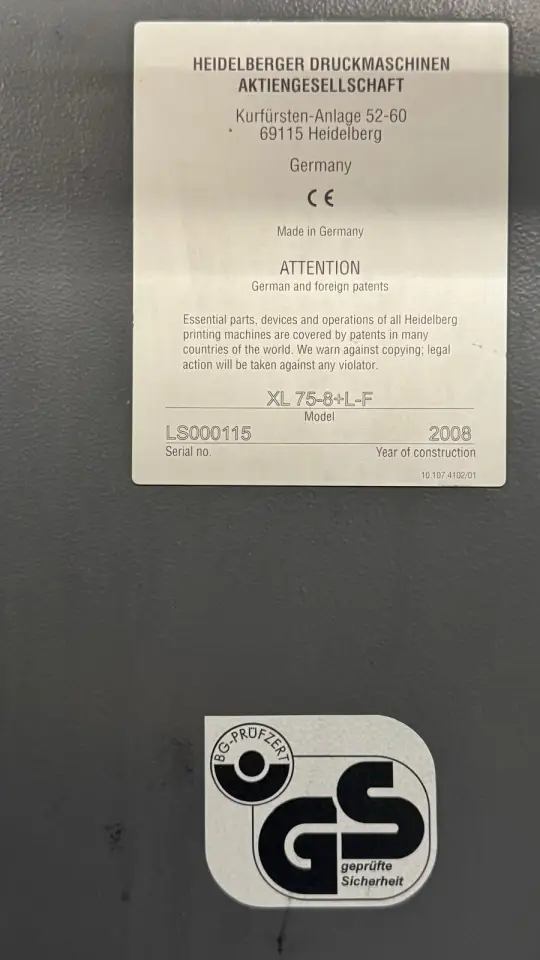

Heidelberg XL75-8 LX3-F Hybrid-Foil

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Heidelberg |

|---|---|

| Model | XL75-8 LX3-F Hybrid-Foil |

| Type | Sheetfed Offset/Offset a foglio |

TECHNICAL DATA

| Max sheet size | 600,5 x 750 |

|---|

Accessories

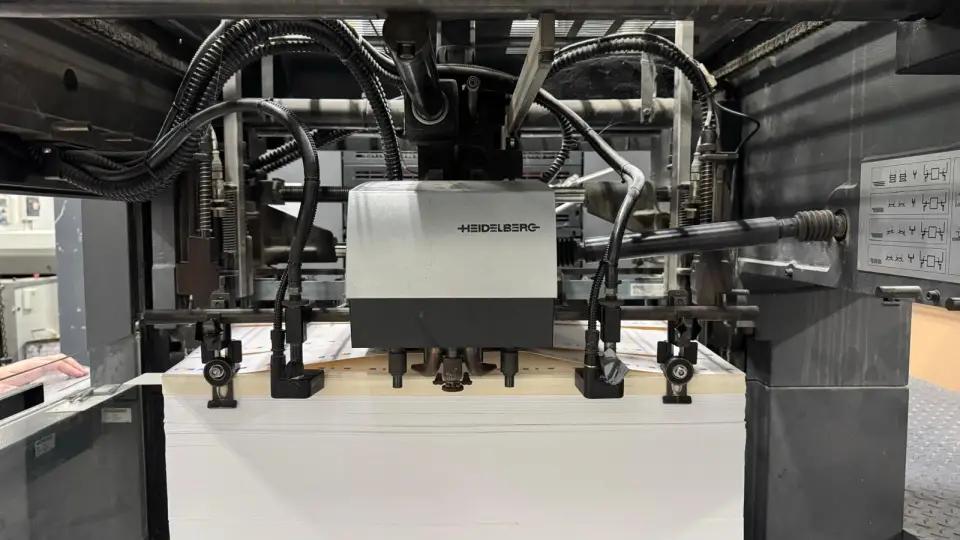

- Console

- Prinect Press Center console touch screen, axial, circumferential and diagonal register remote control, ink ductors rotation control, job memorization

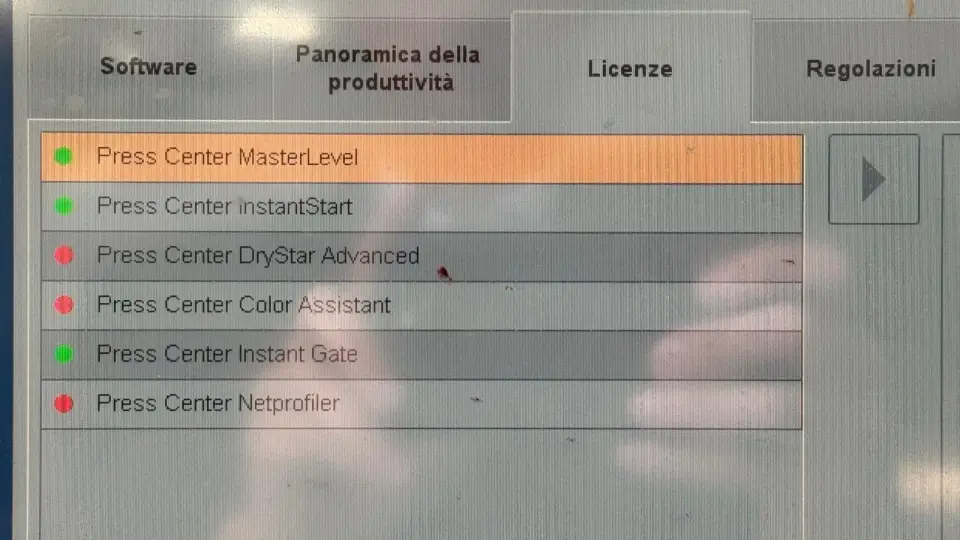

- Prinect Press Center MasterLevel

- Prinect Press Center IntantGate

- Press Center InstantStar

- Feeder

- Pile height sensor

- Pneumatic side register control with integrated auto cleaning and double shee control with direct system

- Ultrasonic double-sheet control

- Double sheet detector - pulling device

- Multiple-sheet detector/ tear-off

- Antistatic device Advanced on feeder

- Printing Units

- Alcolor Vario System damping

- Autoplate : semi-automated plate change

- Double diameter impression cylinders

- Double diameter transfer cylinder between printing units, with Air Transfer System with possibility to adjust automatically it based on thickness of material to print

- Roller wash-up device controlled by Prinect Press Center

- Blanket and impression cylinders automatic washing devices by Prinect Press Center

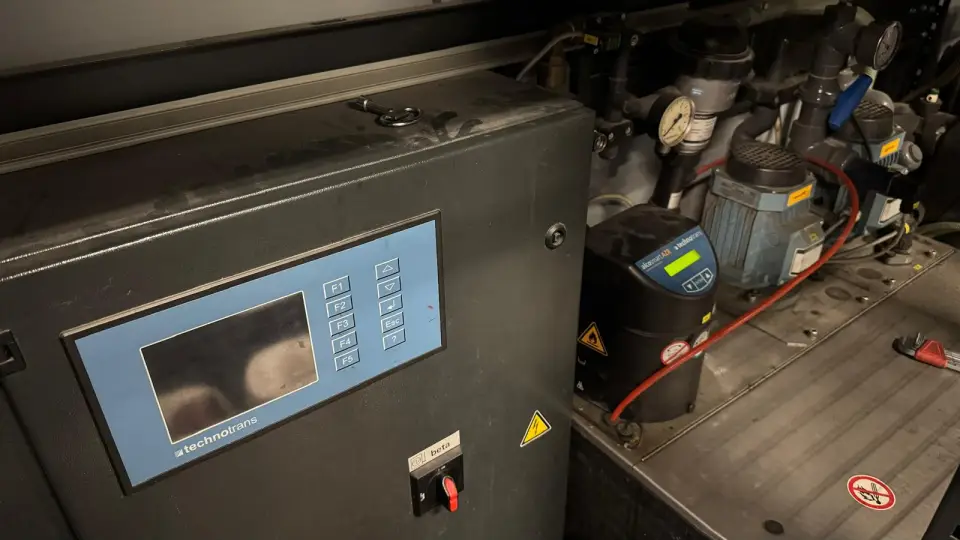

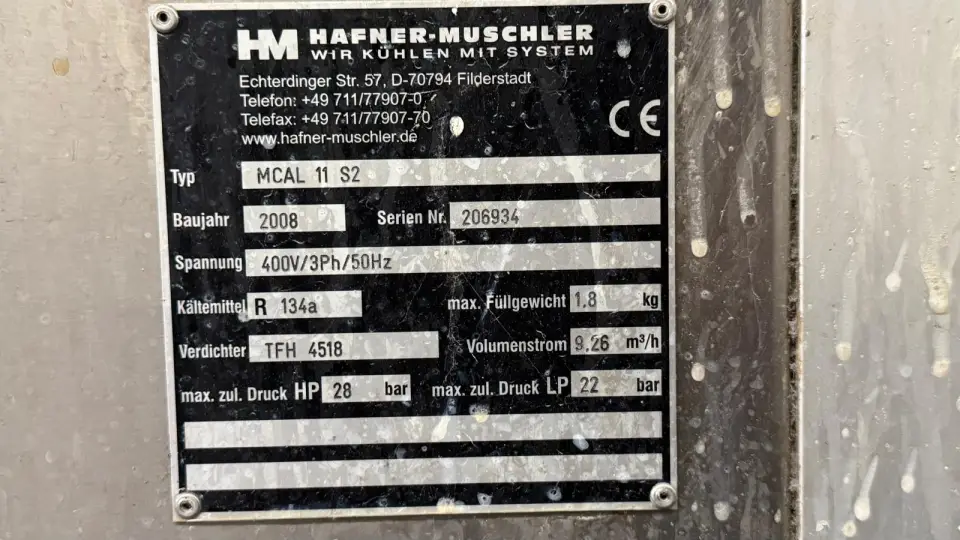

- CombiStar CAN : Technotrans ink temp control combined with damping refrigeration + Alcosmart

- Agitatori di inchiostro Technotrans

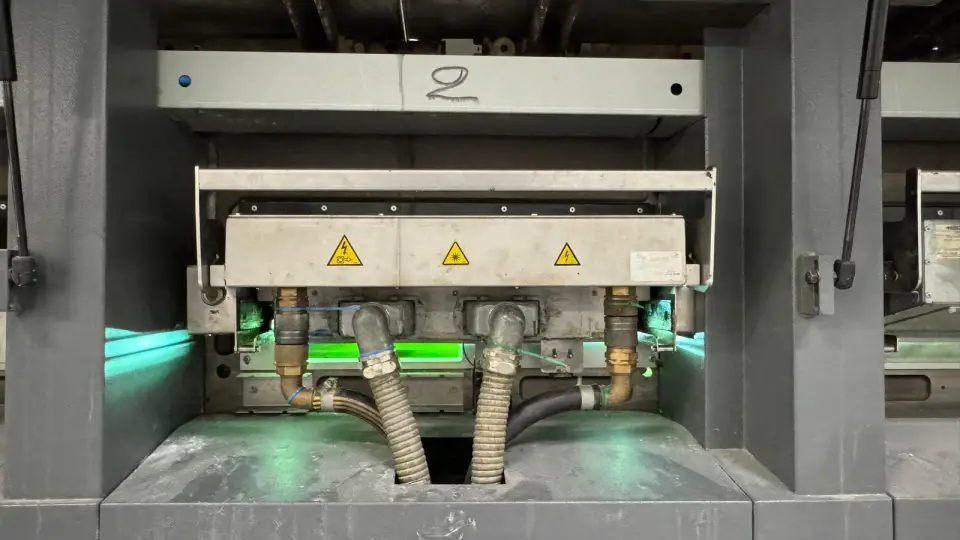

- No.4 UV ZDT separate interdeck dryers

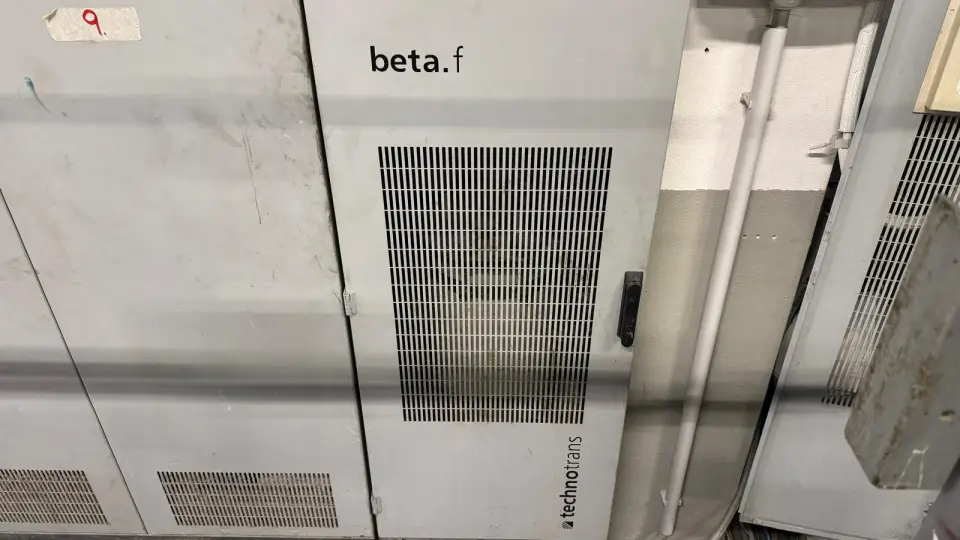

- Technotrans beta.f cabin : dampening solution fine filtration

- Interdeck drying ZDT prepared after 1,2,3,4,5,6,7,8

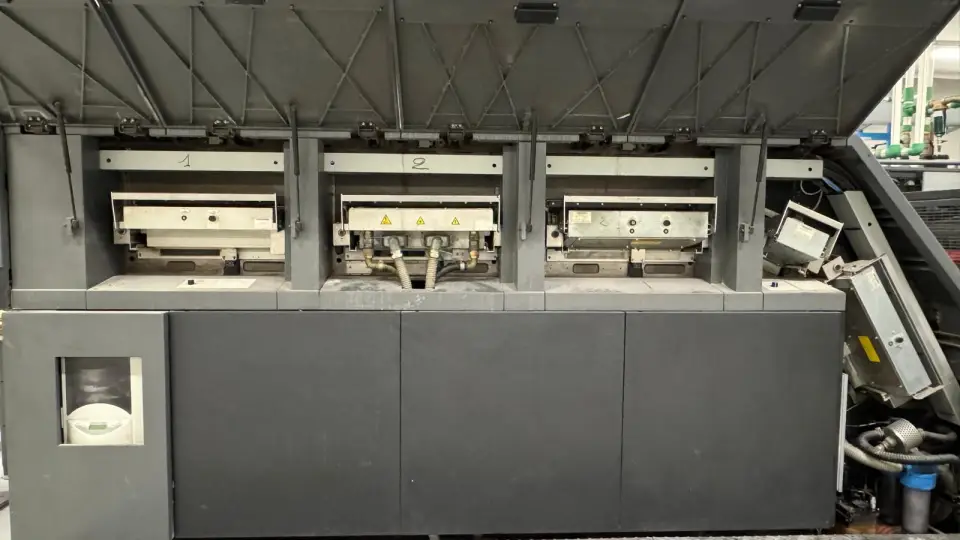

- Varnishing units

- Varnishing unit, with cooking register, Tresu chambered doctor blade system, with anilox roller

- TRESU AQUA L10 Coating Circulator

- Coating Star : heat coater system

- Delivery

- Weko AP230 powder spray device

- Extended Delivery (240 cm / X3)

- Weko AP232 powder spray device

- Antistatic device Advanced on delivery

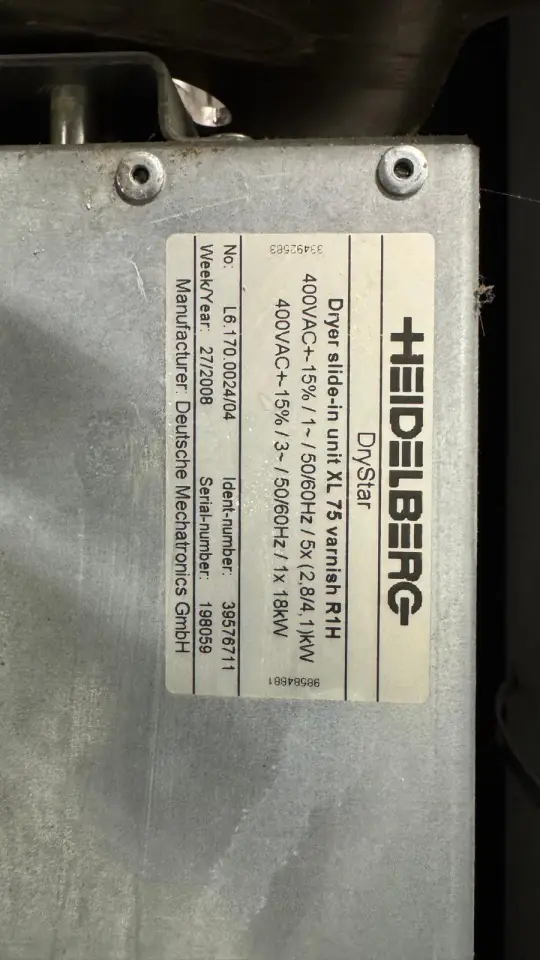

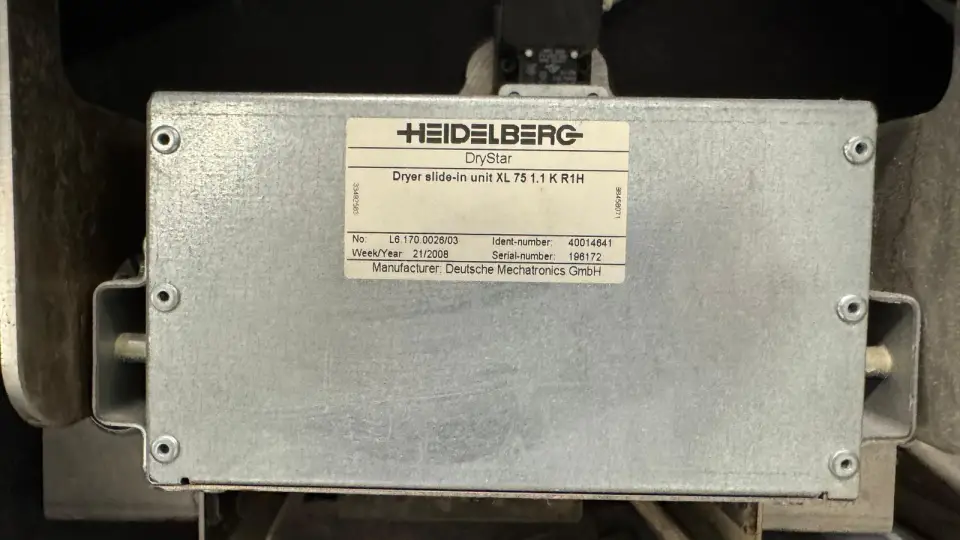

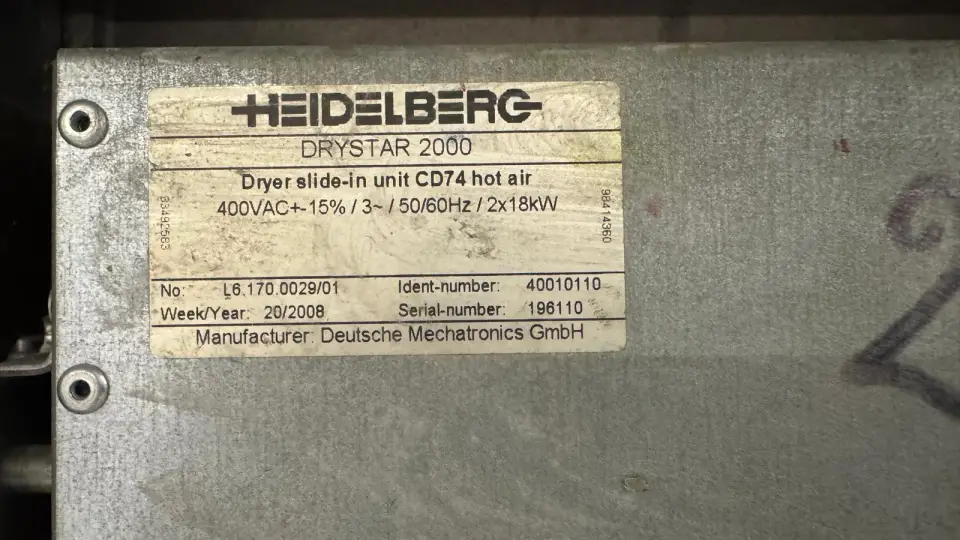

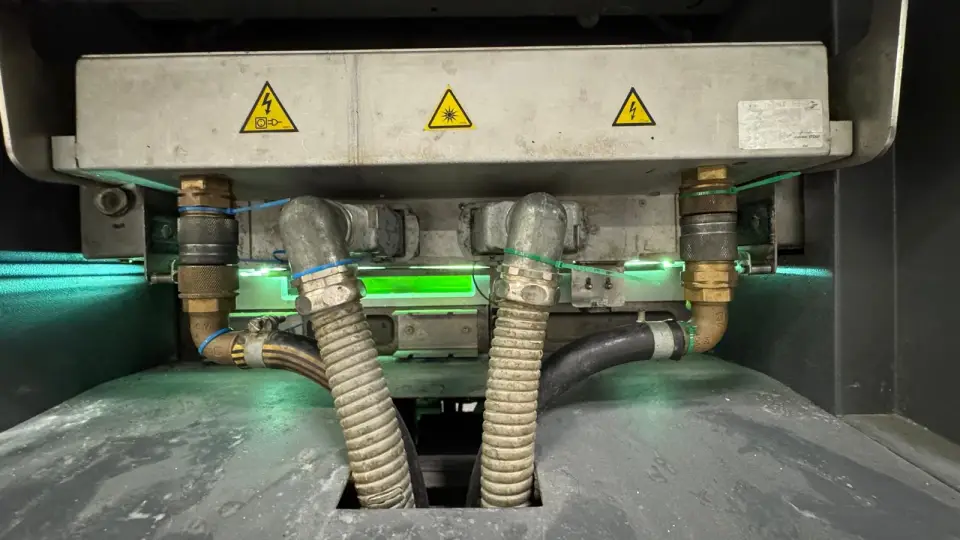

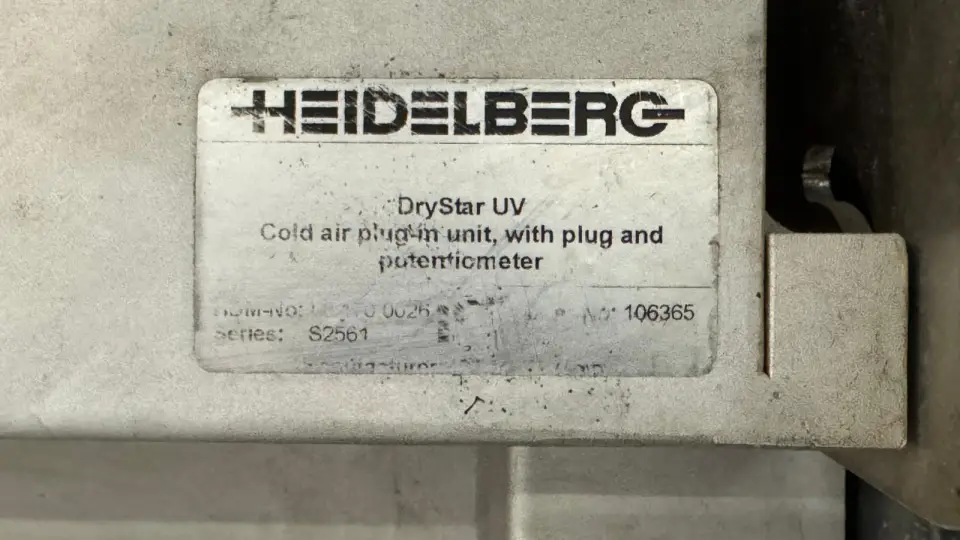

- DryStar 2000 Combination via CanOpen (5 slide-in dryers) : pos. 1 dryer slide-in unit IR/HA hot air; pos. 2 Air; pos. 3 dryer slide-in unit HA hot air; pos. 4 No. x 2 IST UV 200 w. lamps; pos. 5 KL Cold Air.

- Peripherals

- ScrollStar : Atlas Copco compressor

- AirStar Pro : central air box water cooled

- Various

- 15.000 speed/h

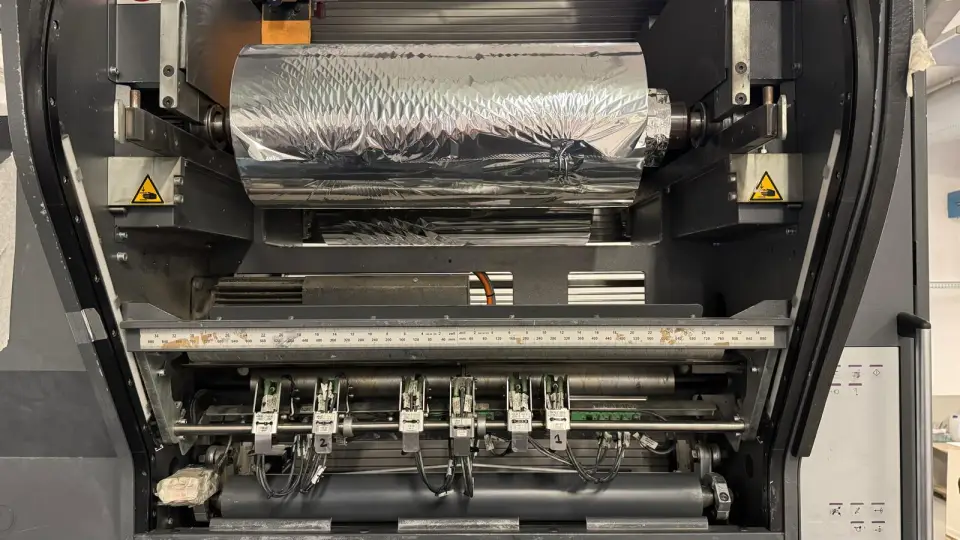

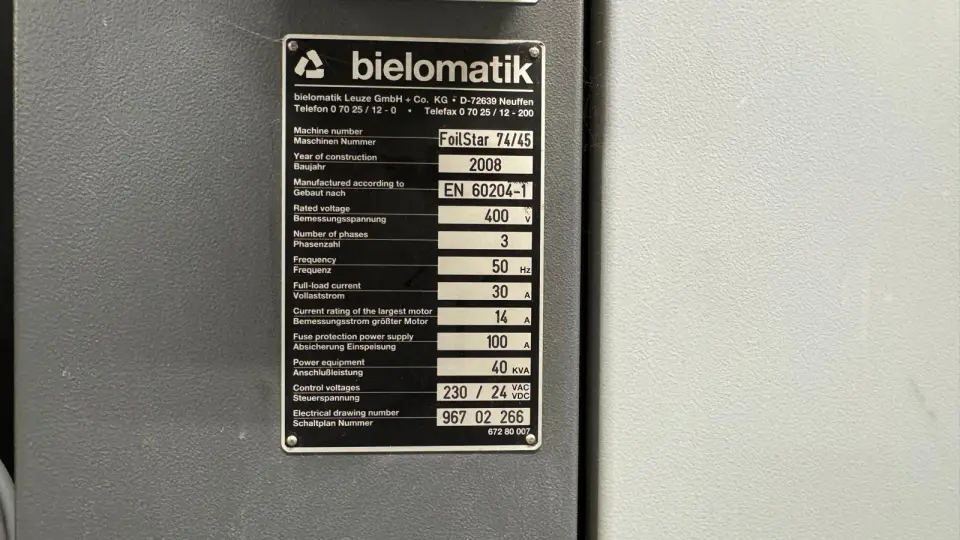

- FoilStar 74/45 Bielomatik

- Technotrans beta.ps cabin : chiller for water cooled cabinets pump and circulation unit with 2 seperate circulations

- Interphone on feeder/delivery

Machine overview

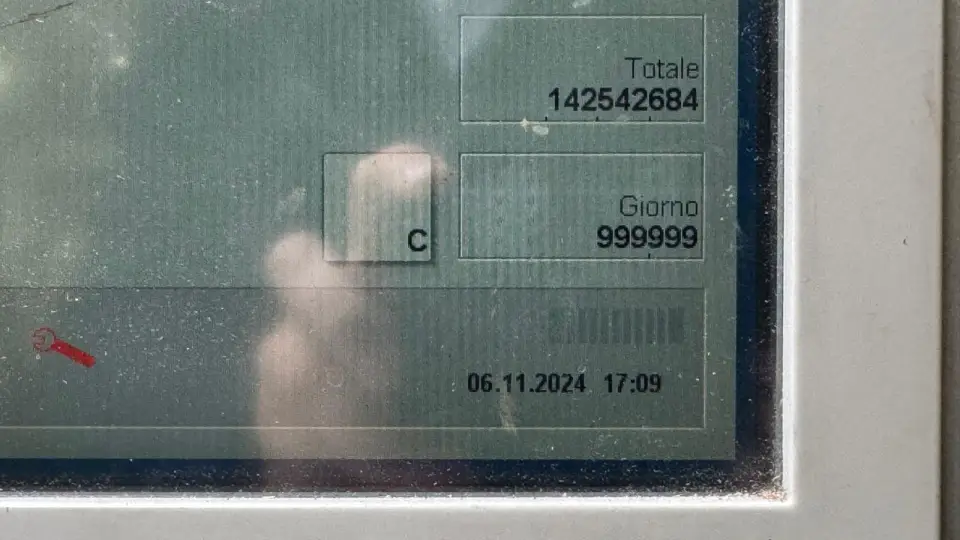

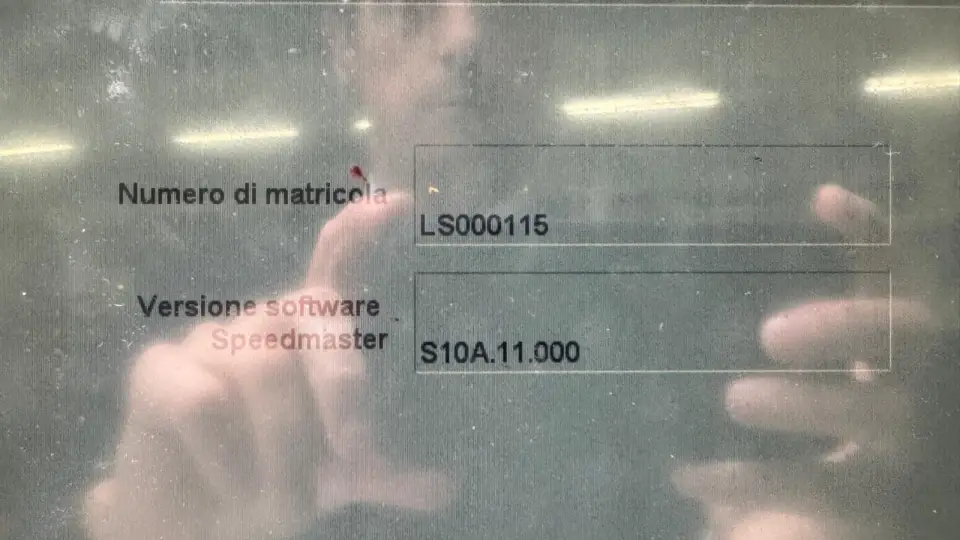

| Year | 2008 |

|---|---|

| Serial Number | LS000115 |

| N.of Impressions | 142 mio. |

“EXTRA” Accessories Overview

- Prinect Press Center IntantGate

- Press Center InstantStar

- Ultrasonic double-sheet control

- Double sheet detector - pulling device

- Multiple-sheet detector/ tear-off

- Antistatic device Advanced on feeder

- Agitatori di inchiostro Technotrans

- No.4 UV ZDT separate interdeck dryers

- Technotrans beta.f cabin : dampening solution fine filtration

- Interdeck drying ZDT prepared after 1,2,3,4,5,6,7,8

- TRESU AQUA L10 Coating Circulator

- Coating Star : heat coater system

- Extended Delivery (240 cm / X3)

- Antistatic device Advanced on delivery

- DryStar 2000 Combination via CanOpen (5 slide-in dryers) : pos. 1 dryer slide-in unit IR/HA hot air; pos. 2 Air; pos. 3 dryer slide-in unit HA hot air; pos. 4 No. x 2 IST UV 200 w. lamps; pos. 5 KL Cold Air.

- AirStar Pro : central air box water cooled

- FoilStar 74/45 Bielomatik

- Technotrans beta.ps cabin : chiller for water cooled cabinets pump and circulation unit with 2 seperate circulations

Reference Overview

| Reference | 20035535 |

|---|---|

| Visible | In production |

| Availability | Immediately |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset