Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

Mitsubishi 3F-4 TC-ED + L

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Mitsubishi |

|---|---|

| Model | 3F-4 TC-ED + L |

| Type | Sheetfed Offset/Offset a foglio |

TECHNICAL DATA

| Max sheet size | 720 x 1020 |

|---|---|

| Min sheet size | 360 x 540 |

| Max print size | 710 x 1020 |

| Material Thickness | 0,04 - 0,6 |

Accessories

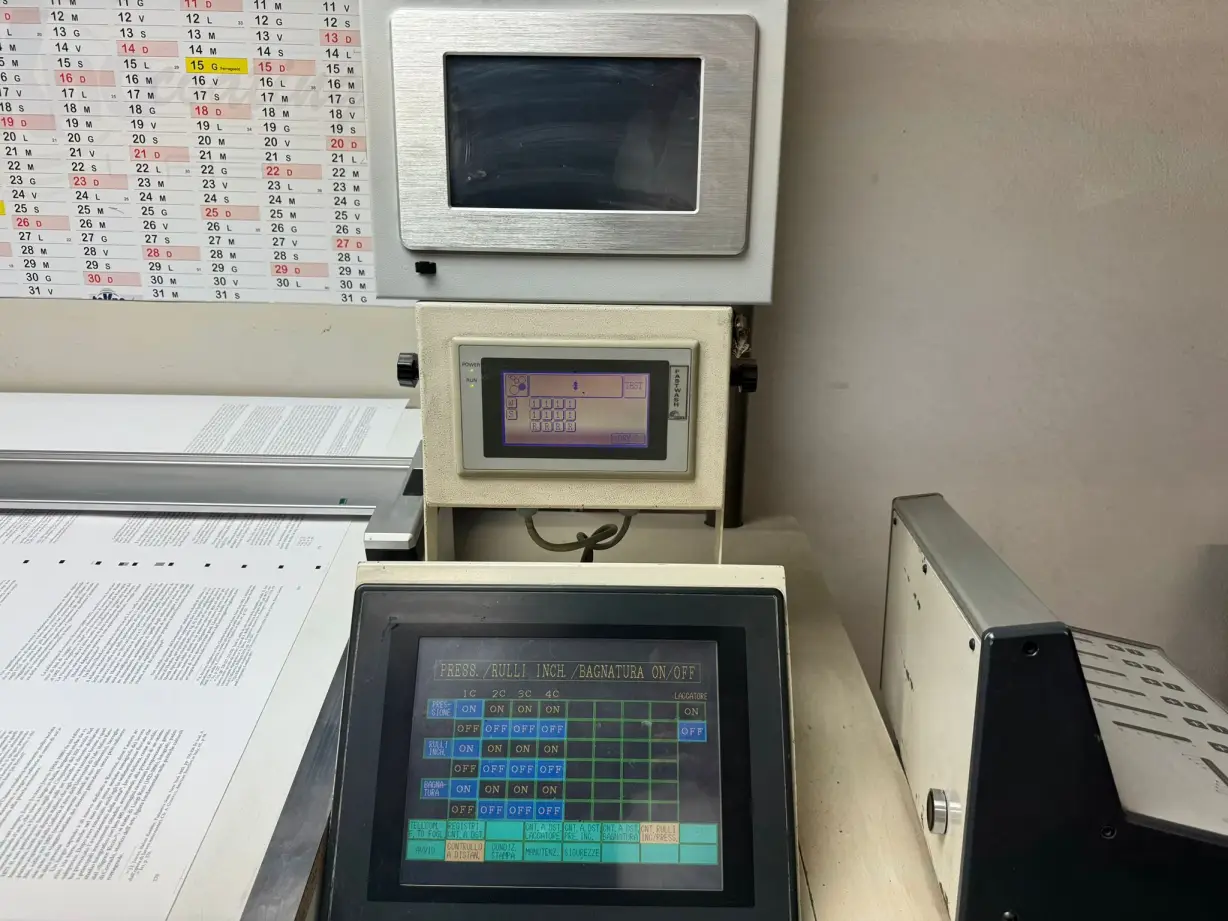

- Console

- Comrac: Console ink, axial, circumferential diagonal remote control

- Feeder

- Mechanic double sheet control

- Steel infeed table with sheet-blocking suction

- Original Head feeder MHI

- Sheet deceleration system on front registers

- Antistatico on feeder

- Remote controlled feeder timing system

- Non-stop on feeder

- Printing Units

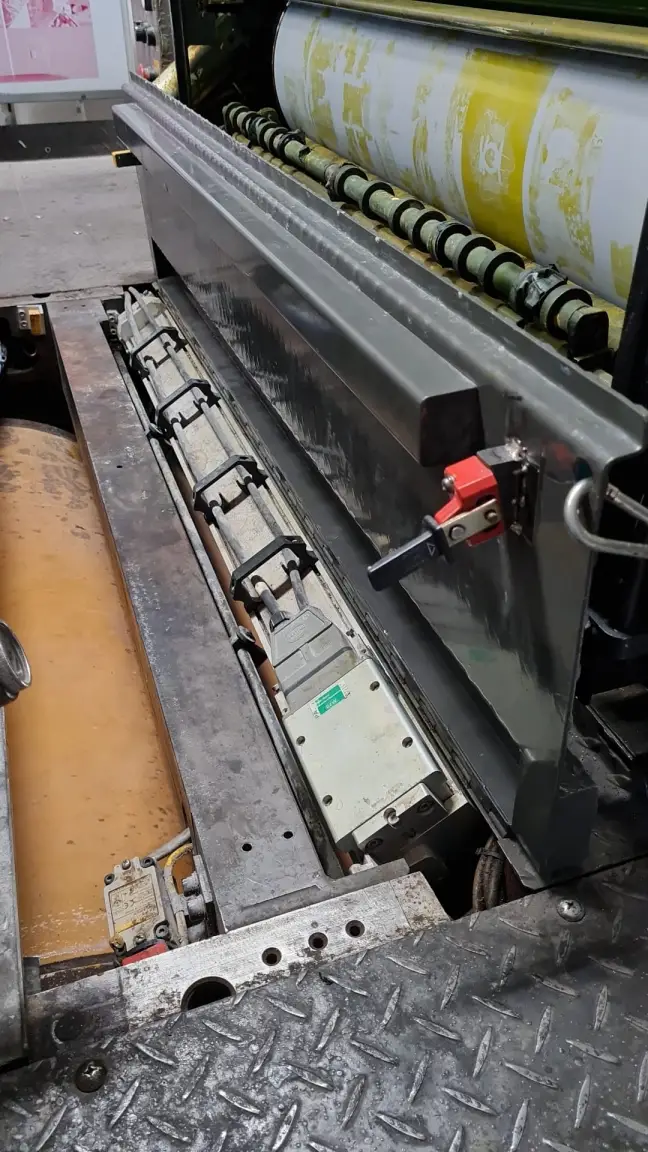

- SAPC Autoplate

- Automatic roller wash-up device

- Blanket cylinder with anti-shock damping system

- Plate and blanket cylinders in metallic steel

- Self-adjusting double conic bearing cylinder support

- Sectors ink blades

- Ink zone reset procedure

- Automatic blanket wash-up device with cloths

- Double diameter impression cylinders

- Double diameter transfer with ICP covering

- Special grippers and pad-grippers for IR Dryer

- Automatic positioning of plate cylinders for Autoplate

- Cylinder arrangement 7 o'clock: Transfer of fully printed sheet from print cylinder to transfer cylinder

- Alcool Mitsubishi trivalent damping

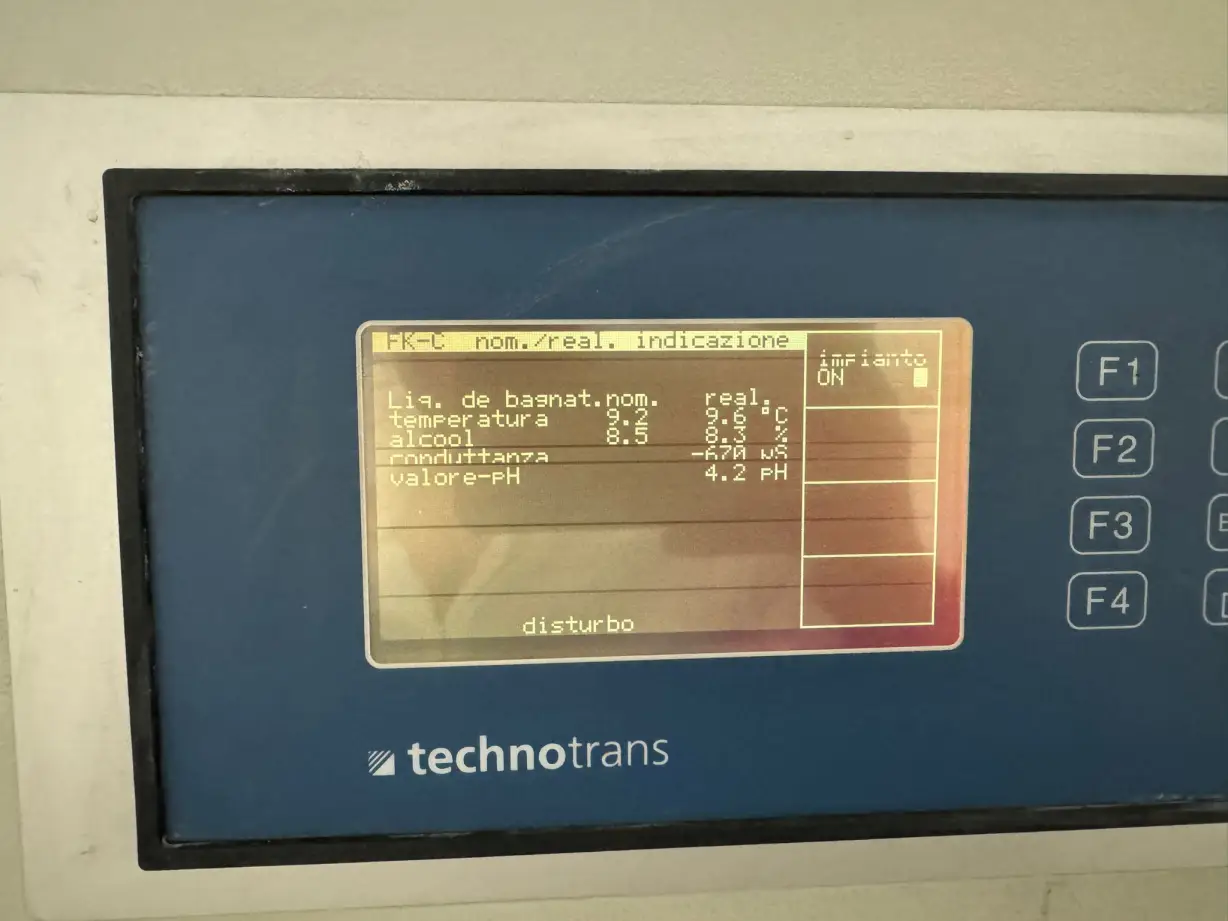

- Technotrans cabin for damping and ink temperature control

- Varnishing units

- Coating Unit with rollers

- Delivery

- Weko T77c powder spray

- Extended Delivery

- Variable speed suction brakes longitudinal laying

- Sheet brake

- 3-sided stack extraction

- Automatic lubrication of chains on delivery

- Non-stop on delivery

- Light paper device on delivery device with fans

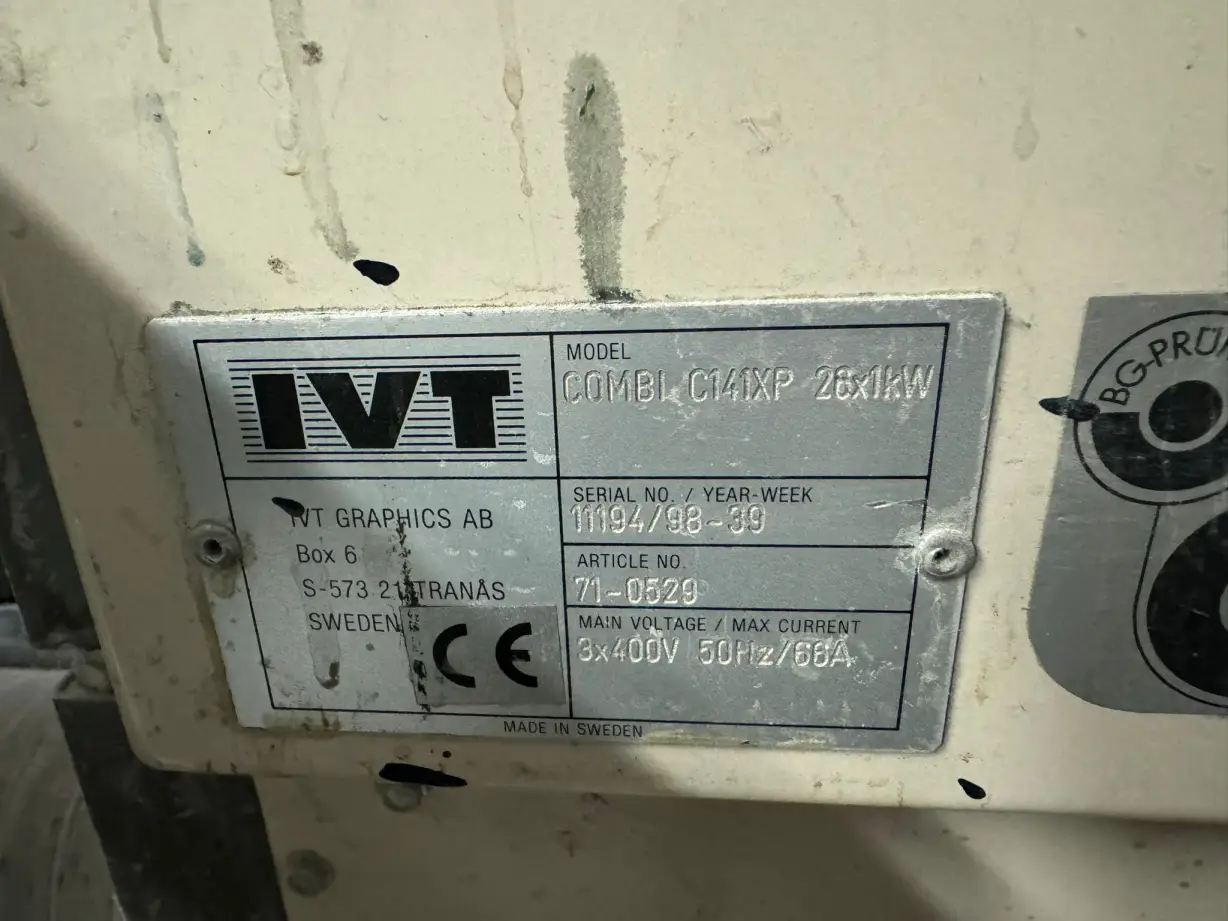

- IR/Hot Air IVT Combi C111

- Various

- 13.000 speed/h

- Printable tickness capacity from 0.04 to 0,6 mm.

- LED UV lamps NOT included

- Dimensions in mm.: 11.600 x 3.800 x 2.100

- Automatic centralized forced oil lubrication system

- Torque wrench for inkwell closing and rubber pulling

Machine overview

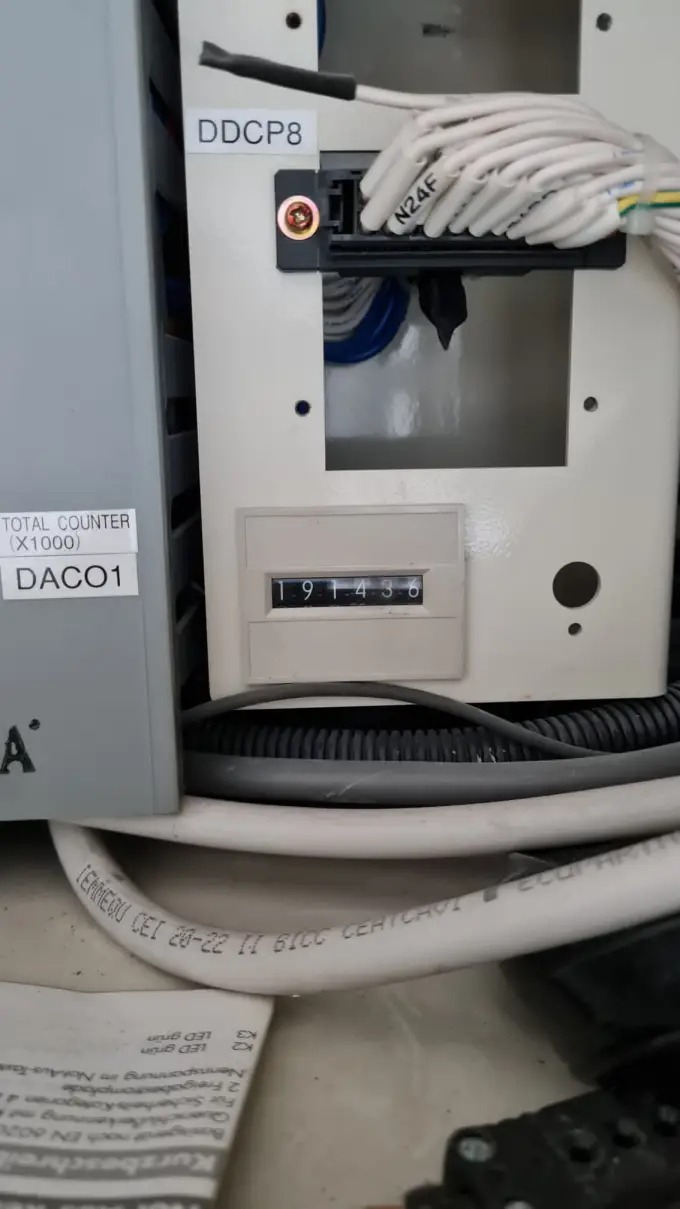

| Year | 1998 |

|---|---|

| Serial Number | 3F 1501 |

| N.of Impressions | 191 mio. |

“EXTRA” Accessories Overview

- Sheet deceleration system on front registers

- Antistatico on feeder

- Remote controlled feeder timing system

- Non-stop on feeder

- Technotrans cabin for damping and ink temperature control

- Non-stop on delivery

- IR/Hot Air IVT Combi C111

- LED UV lamps NOT included

Reference Overview

| Reference | 24036439 |

|---|---|

| Visible | Camporese Rebuilding Center of Limena (PD) |

| Availability | Immediately |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset