Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

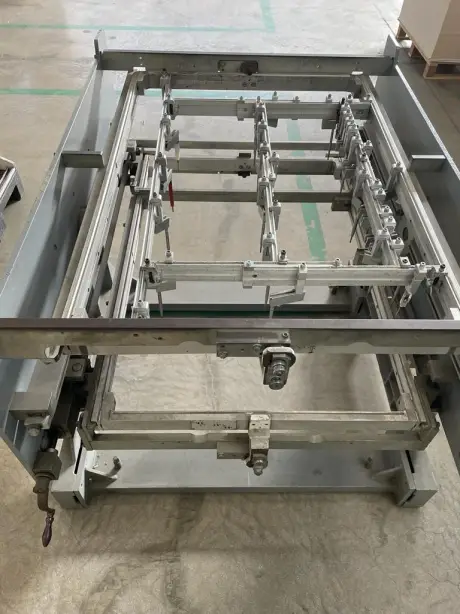

Enlarge

Enlarge

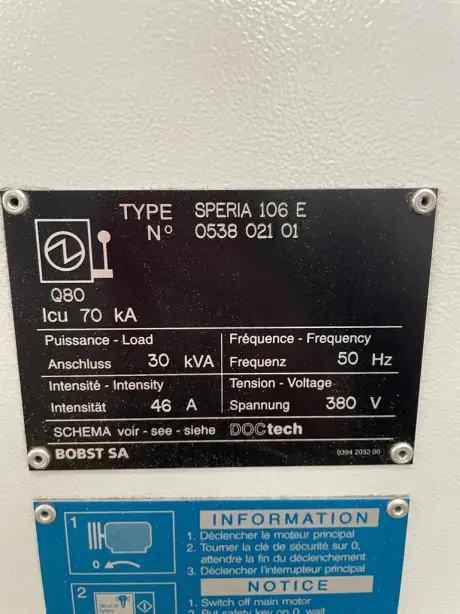

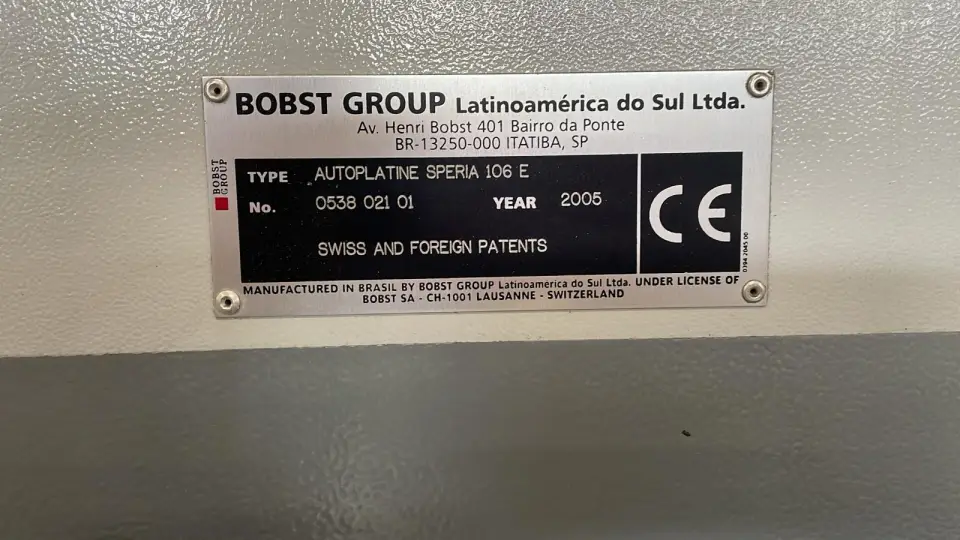

Bobst SPERIA 106 E

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SPERIA 106 E |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 106 x 74 |

|---|---|

| Min sheet size | 40 x 35 |

Accessories

- Machine

- Centerline system for quick job changeover

- Electronic device for sheet travel control

- Adjustable centering on delivery

- Control cabinet cooling unit

- C.U.B.E. (Control Unit Bobst Electronic) for machine operation

- Main motor with frequency variator

- B-7 PLATFORM

- B-28 INSTALLATION OF THE MACHINE WITHOUT EXCAVATION

- M-5 CHASE CHANGER : allows the change and preparation of the chase and the die cutting corresponding to the next job (Includes an increase in the surface of the platform)

- Feeder

- Pile tray with handle allowing manual lateral correction on the pile during production

- Synchronization device timing the sheet arrival against the front lays when the machine is at a standstill

- Pile lifting controlled by Pressfoot

- Rear pile guide (OS and OOS sides)

- Side blowers adjustable with Centerline marks

- Suction unit

- Safety system for lowering the pile try

- C-4 NON-STOP FEEDER MANUAL DEVICE

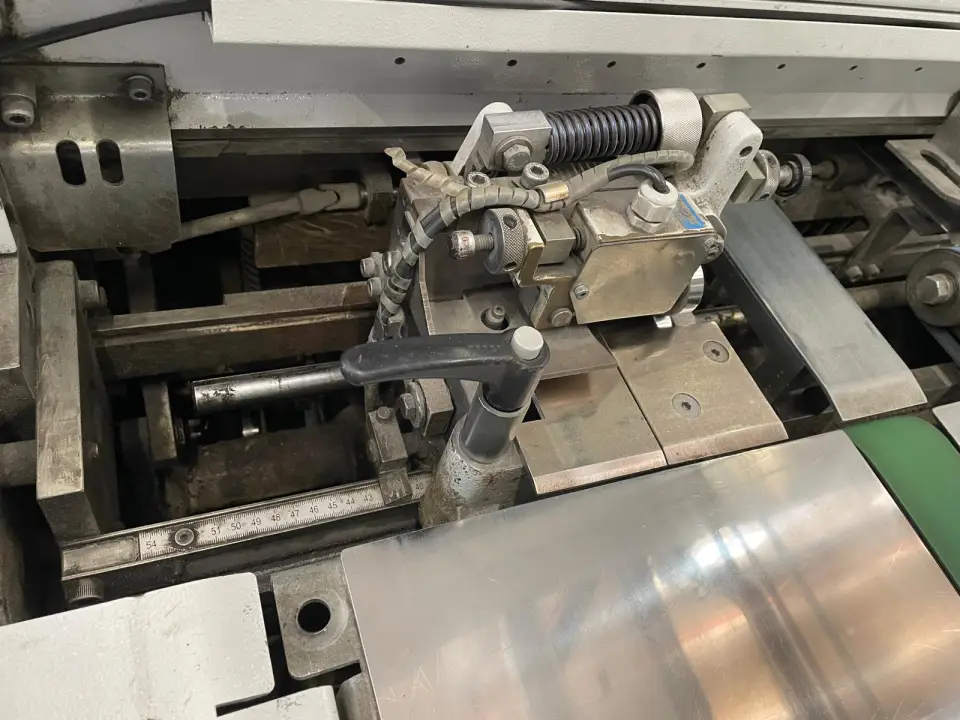

- Platin

- Grippers re-opening device (Platin)

- Cutting plate with micrometric adjustment for 1 mm thin plates

- Equipment centering and locking on platin

- Synthetic material supporting plate on platen (Thickness 23.5 mm (0,925")

- 1 Upper chase-fixed bottom (E-1)

- E-5 COMPENSATING PLATE. THICKNESS 4 MM. IN GROUND STEEL

- E-55 ADJUSTABLE SUPPORTING PLATE CENTERINGS

- E-3 1 UPPER CHASE QUICK-LOCK: FIXED BOTTOM PLATE, THICKNESS 2 MM, AND MAKE-READY PROTECTION PLATE MADE OF SYNTETHIC MATERIAL, THINCKNESS 1 MM.

- 1 Cutting plate (E-4)

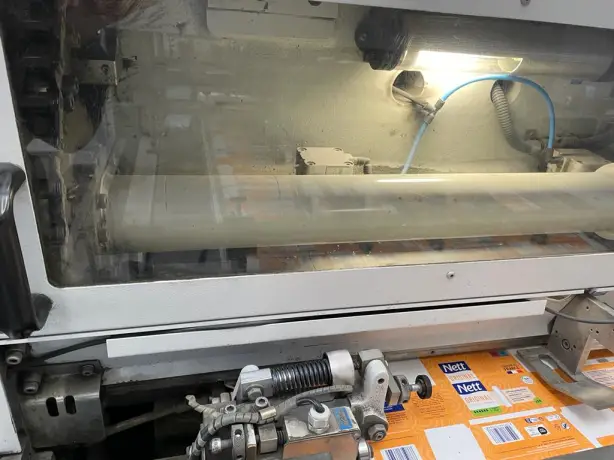

- Stripping Station

- Quick locking device of the central stripping board

- Motorized lifting of the upper frame

- F-2 1 Upper Stripping Frame

- F-31 UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING ((decreases extraction tool assembly times. the quick-closing device allows the tool to be changed in the machine)

- 1 Upper stripping equipment (F-21) required to create a waste stripping tool, including crossbars, clamps, stripper holders and stripping pins of 3, 5 and 10 mm of diameter

- Fastening equipment for stripping die (F-22)

- CENTRAL PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT WITH ALL ITS TOOLS

- 1 Adaption material for stripping board on the central frame (quick locking) (F-76)

- 1 lower pull-out frame (F-8)

- 1 Lower stripping equipment (F-81) Equipment for waste stripping including crossbars, pins and supports

- F-35 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- Delivery

- Adjustable rear and side joggers with Centerline marks in delivery

- G-5 AUTOMATIC NON-STOP BELT : it is automatically introduced on delivery when the pile of sheets is finished

- Various

- Cutting force 260 TON

- 7.700 speed/h (depending on cardboard and type of iob feature)

- Board quality processable : carta (min. 80g/m²); cartone (250/2000 g/m²); corrugate* (3 - 4 mm.) ( * ) Carton acceptable warp : 4% of the widthwise sheet

- Compliant with European Directives for essential safety and health standards relating to design and construction and with American standards UL 508 and NFPA concerning industrial equipment

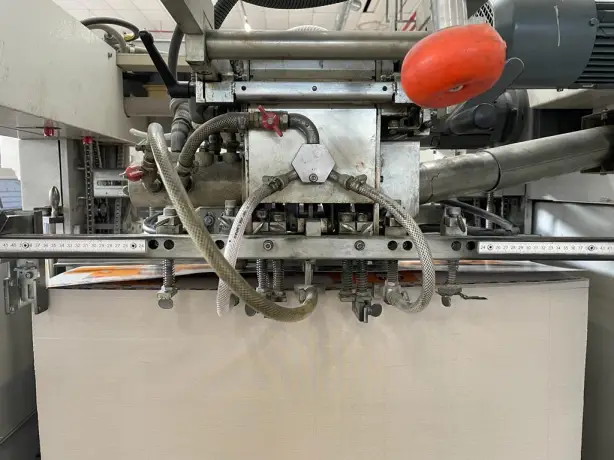

- Tavolo di introduzione

- Covered with an anti-static stainless steel plate

- Transport belts (with lateral guidance and automatic tensionning system)

- 4 front lays, adjustable in pairs with front register control

- Pull-lay operator side (OS) adjustable according to Centerline, with sheet control

- Double sheet detector. Mechanical, integrated on pull guide (OS)

- Sheet-hold down device (guiding the sheets to front lays)

- Upper transport equipment for paper, paperboard and corrugated board

- C-5 SYNCHRONIZATION DEVICE TIMING THE SHEET ARRIVAL AGAINST THE FRONT LAYS WHEN THE MACHINE IS AT A STANDSTILL

- D-3 PUSH GUIDE (OOS opposite operator side)

- "Pull" guide (OS) adjustable according to Centerline marks, with side register control

Machine overview

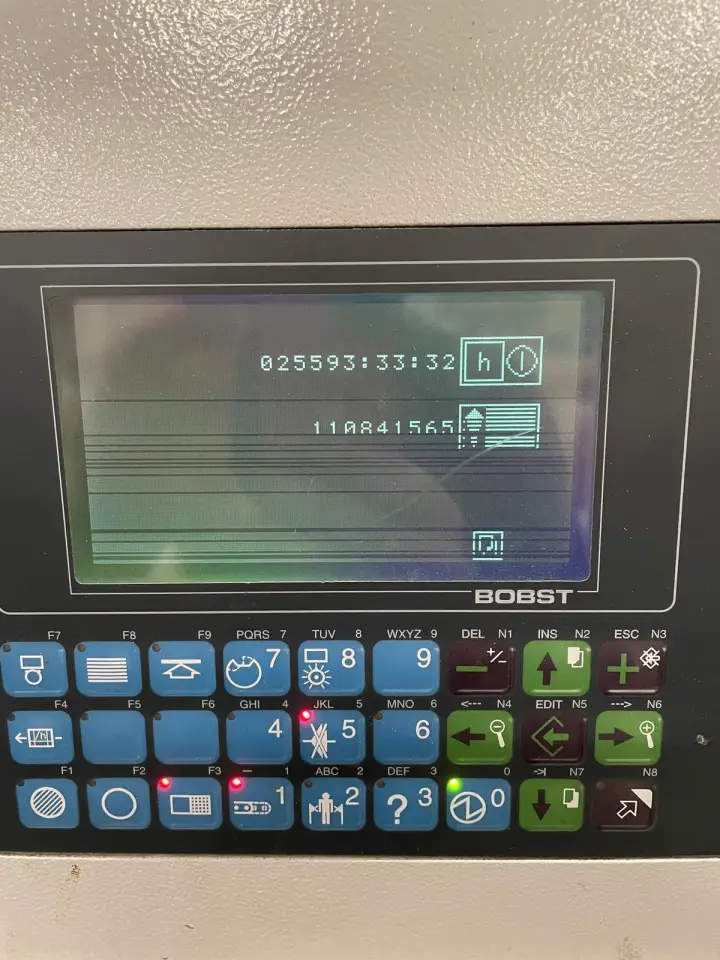

| Year | 2005 |

|---|---|

| Serial Number | 053802101 |

| N.of Impressions | 110.0 mio. |

“EXTRA” Accessories Overview

- B-7 PLATFORM

- B-28 INSTALLATION OF THE MACHINE WITHOUT EXCAVATION

- M-5 CHASE CHANGER : allows the change and preparation of the chase and the die cutting corresponding to the next job (Includes an increase in the surface of the platform)

- C-4 NON-STOP FEEDER MANUAL DEVICE

- E-5 COMPENSATING PLATE. THICKNESS 4 MM. IN GROUND STEEL

- E-55 ADJUSTABLE SUPPORTING PLATE CENTERINGS

- E-3 1 UPPER CHASE QUICK-LOCK: FIXED BOTTOM PLATE, THICKNESS 2 MM, AND MAKE-READY PROTECTION PLATE MADE OF SYNTETHIC MATERIAL, THINCKNESS 1 MM.

- F-31 UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING ((decreases extraction tool assembly times. the quick-closing device allows the tool to be changed in the machine)

- CENTRAL PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT WITH ALL ITS TOOLS

- F-35 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- G-5 AUTOMATIC NON-STOP BELT : it is automatically introduced on delivery when the pile of sheets is finished

- C-5 SYNCHRONIZATION DEVICE TIMING THE SHEET ARRIVAL AGAINST THE FRONT LAYS WHEN THE MACHINE IS AT A STANDSTILL

- D-3 PUSH GUIDE (OOS opposite operator side)

Reference Overview

| Reference | 24036406 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset