Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

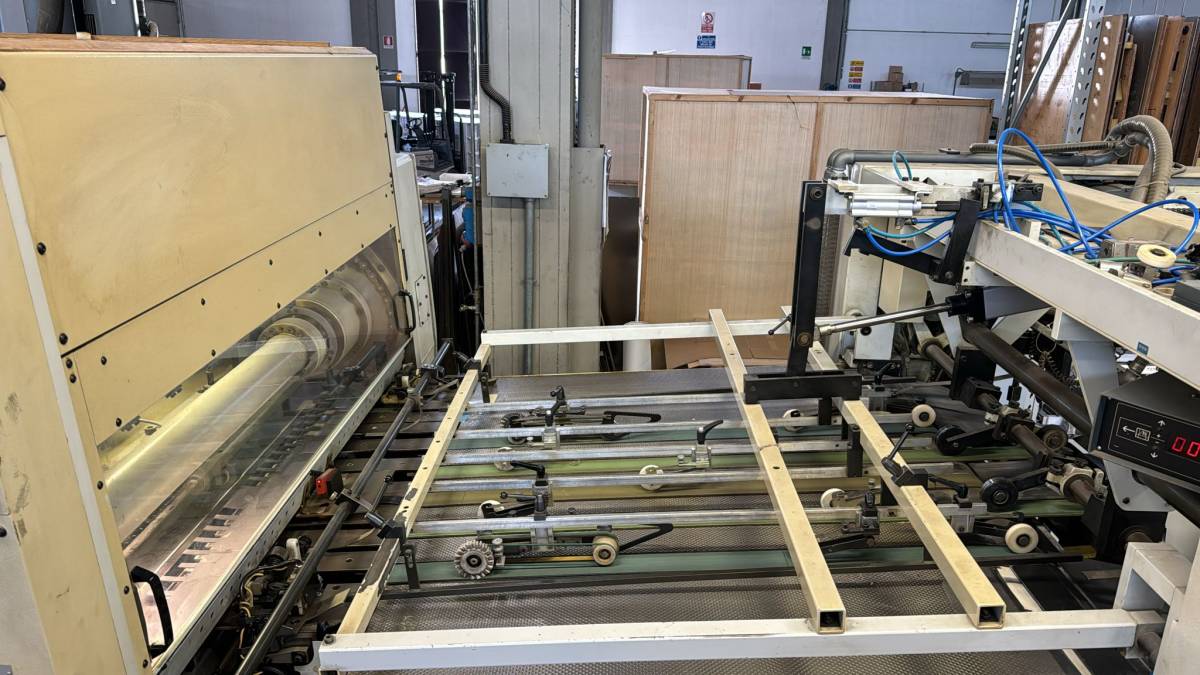

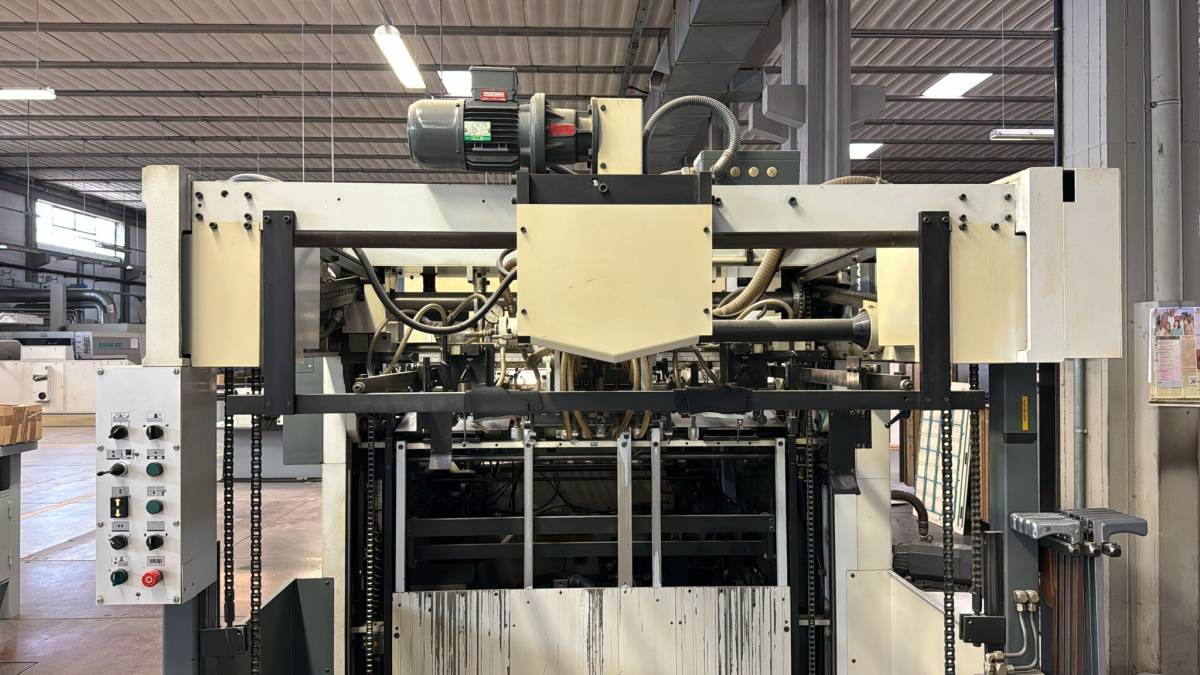

Bobst SP 142 E

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 142 E |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1020 x 1420 |

|---|

Accessories

- Machine

- Step with safety barriers

- Centerline system for quick job changeover

- Electronic device for the sheet passage control

- Gripper bars

- Bobst-Electronic for the machine control

- Main motor

- Feeder

- Manual non-stop device

- Stack holder platform with automatic system for lateral correction via feelers (adjustable with Centerline marks) or manual system via a selector, during production

- Automatic movement of the stack holder platform adjustable in the direction of travel

- Synchronizer to regulate the arrival of sheets to the registers

- Pile height control at the front edge thanks to a photoelectric cell

- Lateral blowers adjustable with Centerline references

- Suction unit

- Safety system for lowering the pile try

- Introduction table

- Covered with an anti-static stainless steel plate

- Adjustable sheet synchronizer while running, allows to adapt the feeder cycle to that of the platen

- 4 Front lays, adjustable in pairs with front register control, with sheet presence

- Pull-lay operator side (OS) adjustable according to Centerline, with sheet control

- Pull-lay opposite operator side (OOS) adjustable according to Centerline, with sheet control

- Double sheet detector

- Sheet-hold down device (Introduction sheets guide in gripper)

- D-7 REINFORCED SHEET TRANSPORT EQUIPMENT for rigid and corrugate cardboard included: Introducers and upper belts - Upper transport elements (wide belts)

- Side-guided transport belts

- Upper frame with pneumatic lifting device

- Platin

- Grippers re-opening device

- Die-cutting device without band of gripper grip

- Equipment centering and locking

- Locking of the chase against the upper beam

- Measurement of the die-cutting force using an electronic probe

- Resocell: synthetic material supporting plate

- SHEET BRAKES DEVICE BY "BERNOULLI" SYSTEM ON PLATIN

- 1 Upper frame: with fixed bottom (E-1). Bottom sheet, 2 mm thick and synthetic protection plate, 1 mm thick

- 1 Cutting plate (E-4)

- Stripping Station

- 3 drawer frames system

- SHEET BRAKES DEVICE BY "BERNOULLI" SYSTEM ON STRIPPING STATION

- Quick locking device of the central stripping board on Waste Stripping Station

- 1 Upper pull-out frame (F-2)

- 1 Upper stripping equipment (F-21) required to create a waste stripping tool, including crossbars, clamps, stripper holders and stripping pins of 3, 5 and 10 mm of diameter

- 1 Fastening equipment for stripping die (F-22) Including crossbars and clamps

- 1 lower pull-out frame (F-8)

- F-81 lower stripping equipment for waste stripping (F-81) Including crossbars, pins and supports

- 1 "GRID" UPPER PULL-OUT FRAME WITH ALL ITS STANDARD TOOLS

- Delivery

- Pile tray

- Adjustable rear and side joggers with Centerline marks

- Sheet shredder special device

- Guillotine device for front trim with lateral evacuation belt

- G-5 AUTOMATIC NON-STOP ON DELIVERY

- SHEET BRAKES DEVICE BY "BERNOULLI" SYSTEM ON DELIVERY

- Conformity to standards and security

- The Autoplaten Presses SP 142-E is in conformity with the European Directives for the Safety and Health requirements related to its design and construction, sa well American standards UL 508 and NFPA related to industrial equipment

- Emergency Stops

- Operator safety devices

- Gripper Bar Chain Slip Clutch

- Gripper bar chain locking device

- Handling of the diecutting equipment

- Photoelectric cell safety barriers located at the feeder and at the delivery

Machine overview

| Year | 1998 |

|---|---|

| Serial Number | 057406402 |

| N.of working hours | 25571 |

“EXTRA” Accessories Overview

- D-7 REINFORCED SHEET TRANSPORT EQUIPMENT for rigid and corrugate cardboard included: Introducers and upper belts - Upper transport elements (wide belts)

- Upper frame with pneumatic lifting device

- 1 "GRID" UPPER PULL-OUT FRAME WITH ALL ITS STANDARD TOOLS

- G-5 AUTOMATIC NON-STOP ON DELIVERY

- SHEET BRAKES DEVICE BY "BERNOULLI" SYSTEM ON DELIVERY

Reference Overview

| Reference | 20035625 |

|---|---|

| Visible | In production |

| Availability | Immediately |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset