Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

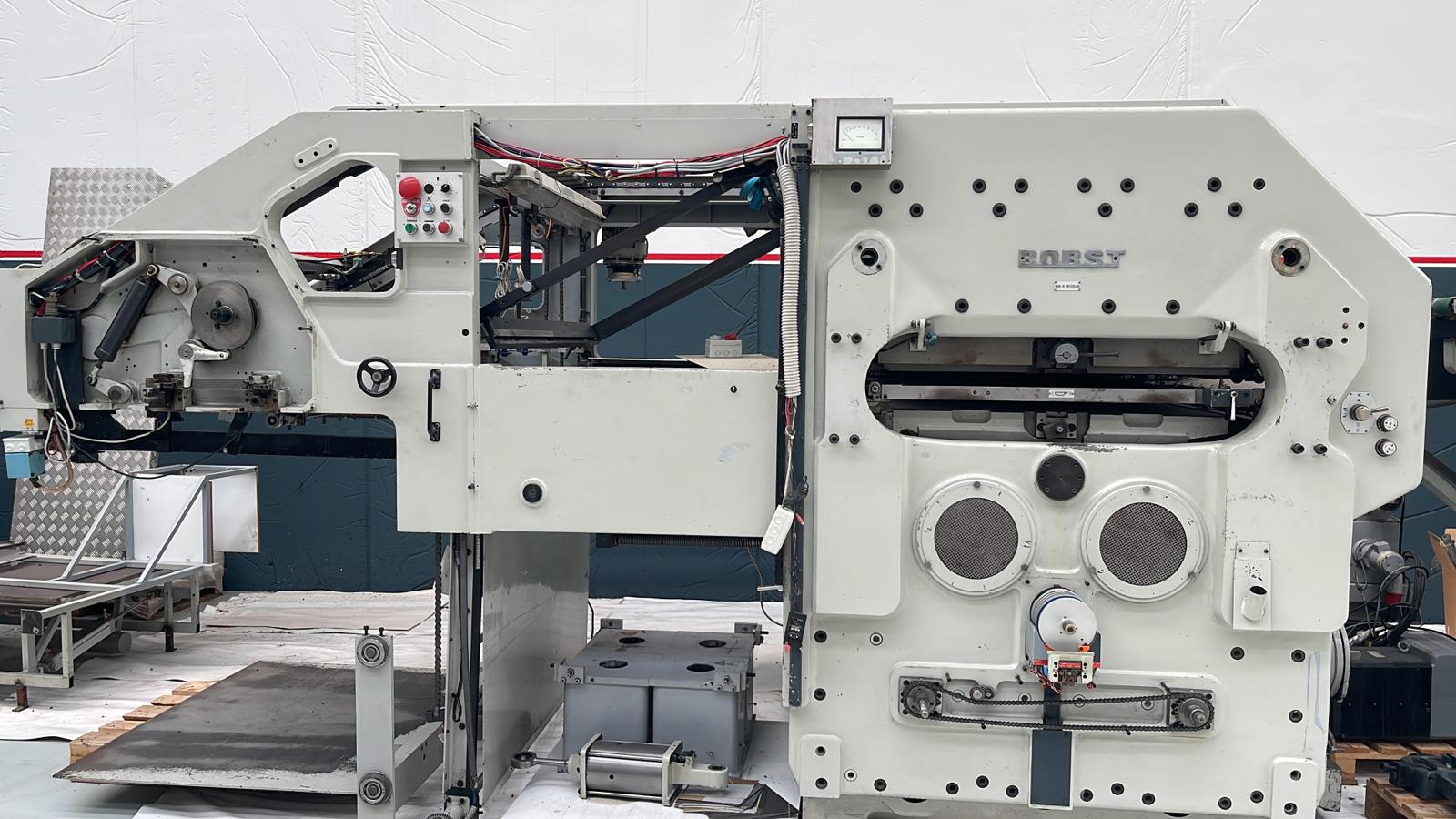

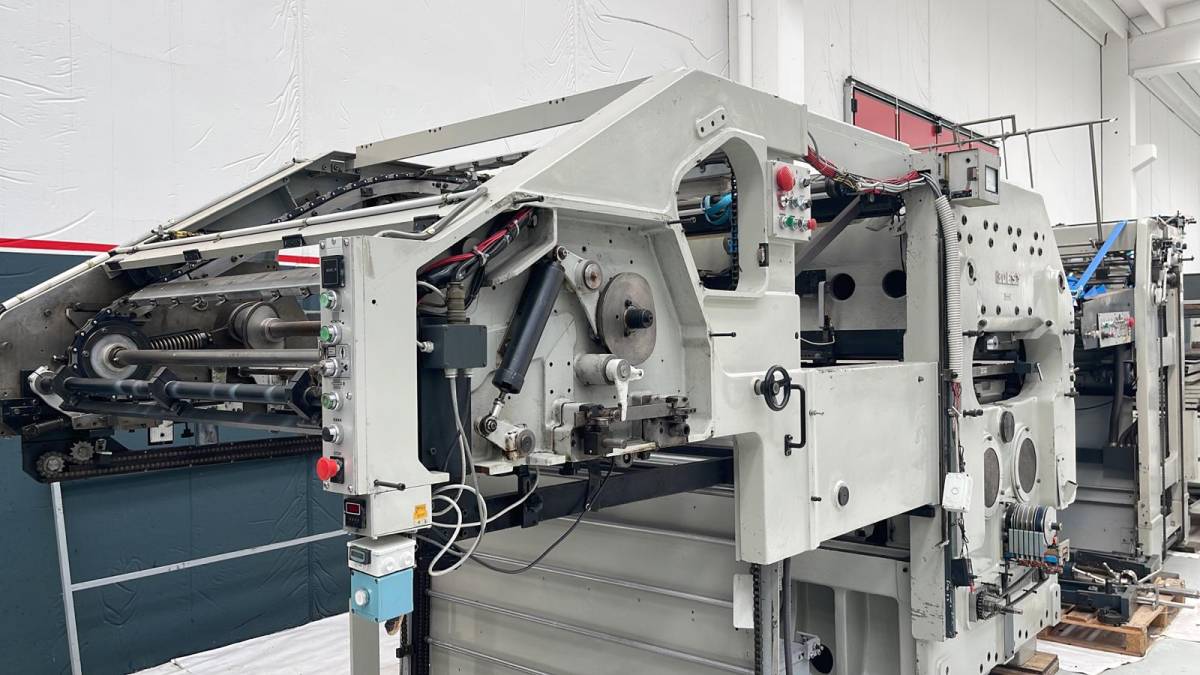

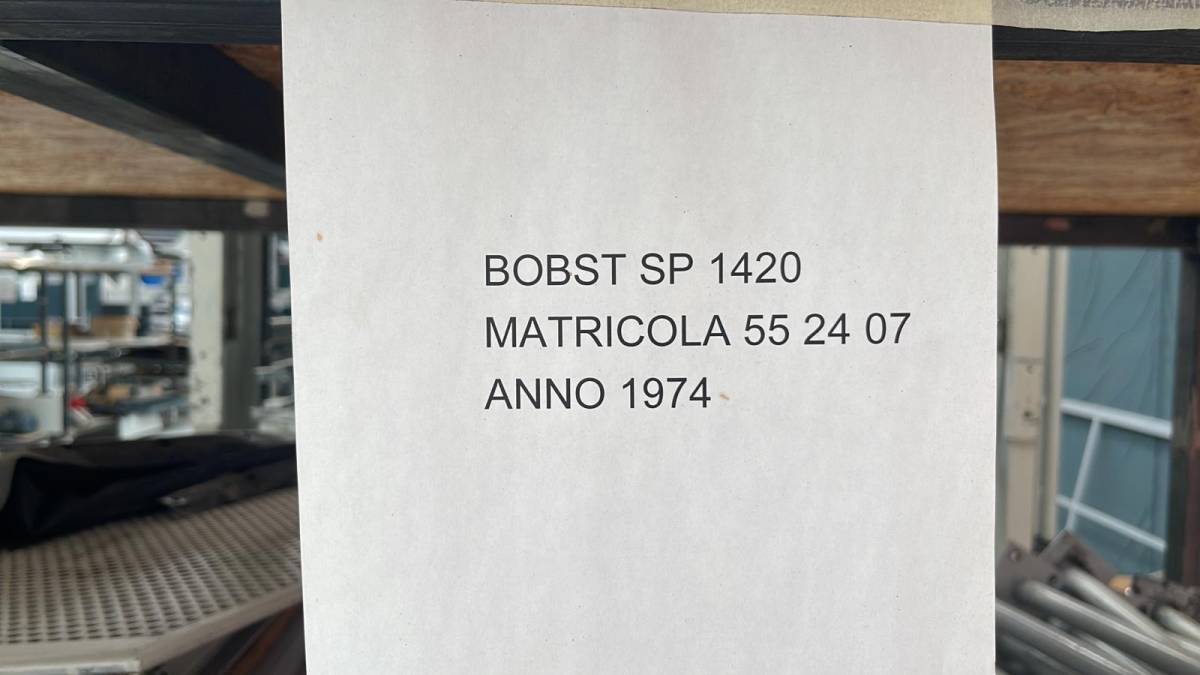

Bobst SP 1420 E

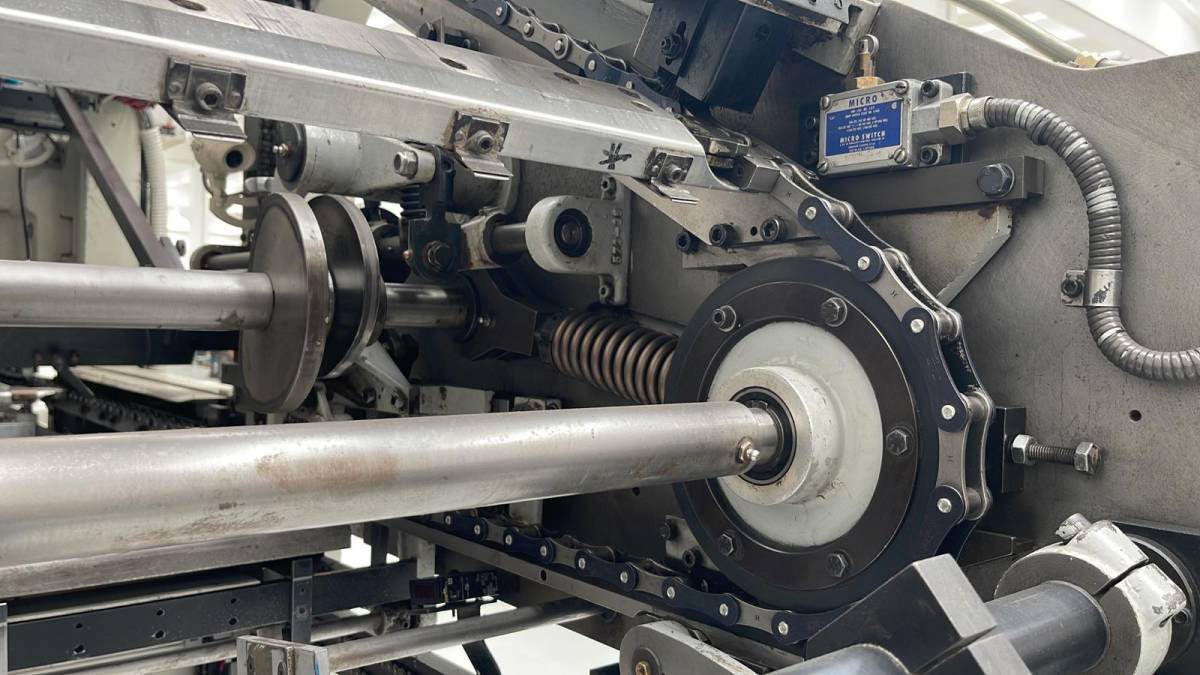

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 1420 E |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1420 x 1020 |

|---|---|

| Min sheet size | 700 x 500 |

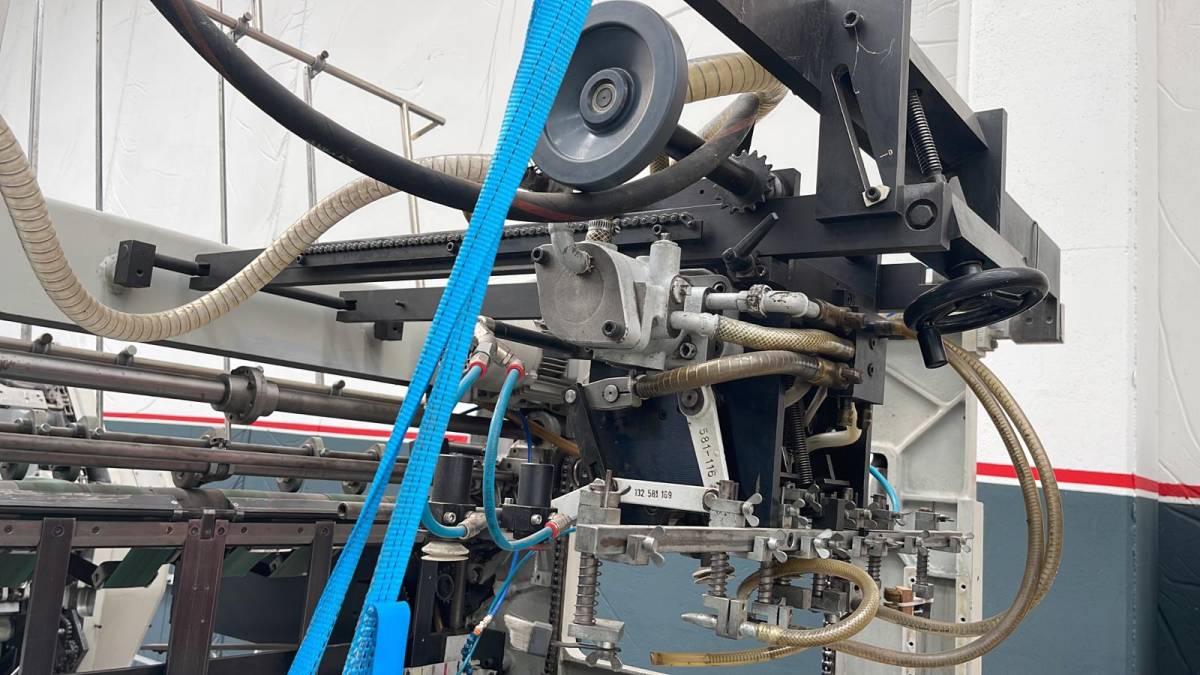

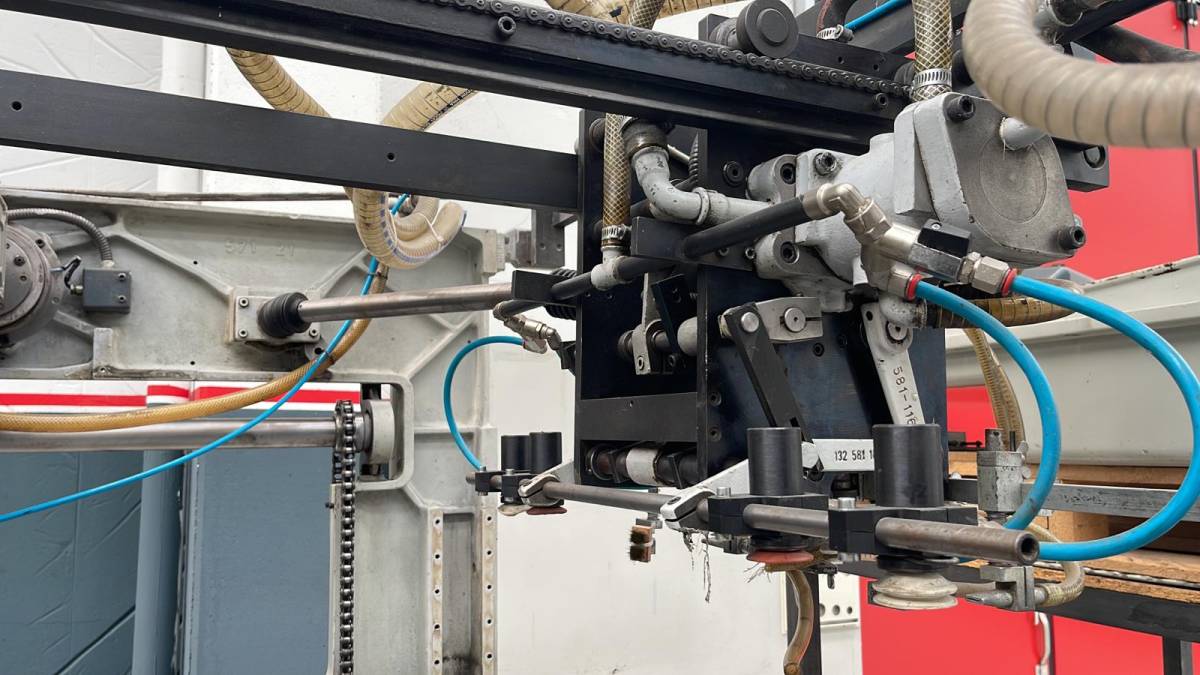

Accessories

- Feeder

- Square type feeder head

- Push lay opposite operator side

- Pull lay operator side with double bearing kit for microwave

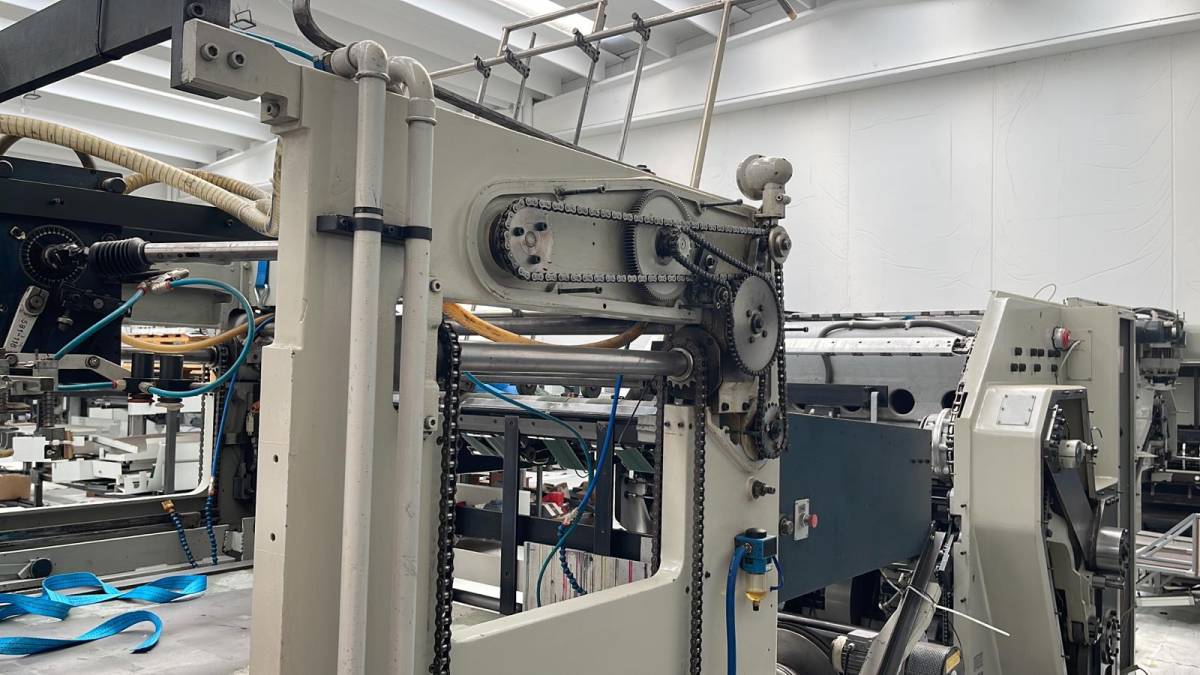

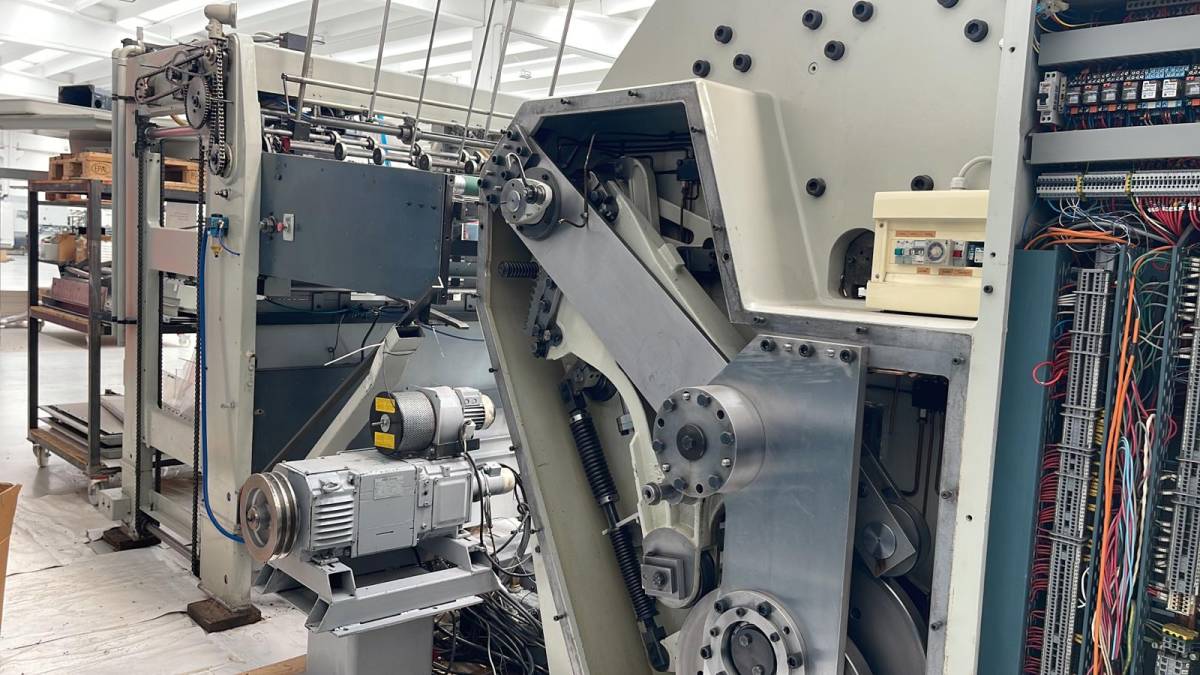

- Delivery

- Non-stop delivery with belt convey

- Various

- Elevated 350 mm

Machine overview

| Year | 1974 |

|---|---|

| Serial Number | 552407 |

“EXTRA” Accessories Overview

- Square type feeder head

- Pull lay operator side with double bearing kit for microwave

Reference Overview

| Reference | 20035841 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset