Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

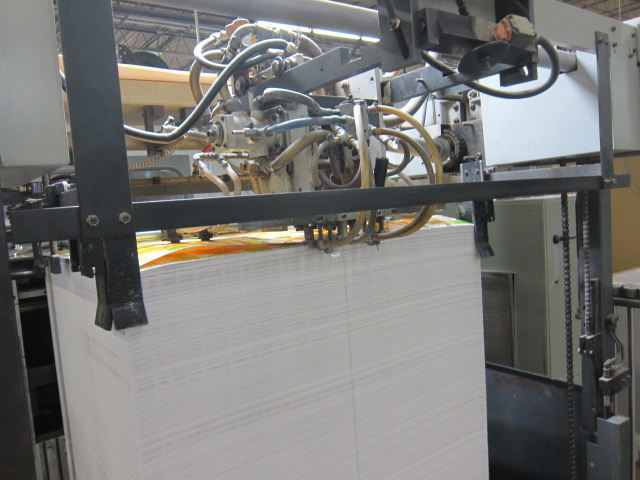

Enlarge

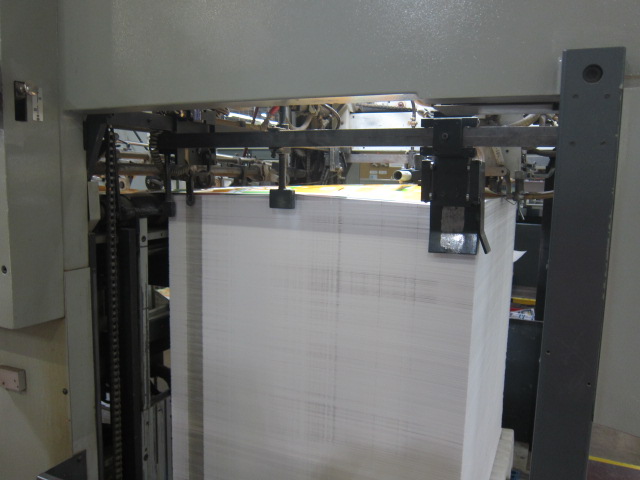

Enlarge

Bobst SP 130 ER

Yes, Bobst is a well-known leader in the die-cutting industry, providing innovative machinery solutions for packaging production. Over the years, Bobst has continued to enhance its die-cutting technology, focusing on improving efficiency, precision, and productivity. One notable development in their offerings is the inclusion of blanking stations in their die-cutting machines.

A blanking station is an important feature that automatically separates the die-cut products (such as cardboard or paperboard blanks) from the waste, creating a clean, efficient process for high-volume production. The addition of blanking stations to die-cutting machines is part of a broader industry trend towards automation and streamlining workflows, reducing manual labour, and improving overall production efficiency.

By integrating blanking stations, Bobst is meeting the growing demand for more automated, faster, and efficient solutions, especially in industries like packaging and printing where time and precision are crucial. This also reflects the increasing focus on reducing material waste, enhancing productivity, and lowering costs for manufacturers, all of which are key competitive advantages in the market.

The move to sell more machines with blanking stations aligns with the industry’s broader push towards automation and smart manufacturing solutions. It helps companies save time, reduce human error, and enhance overall efficiency, while also improving safety on the production floor.

Would you like more details about the specific machines or technologies Bobst is offering with blanking stations? We have a list of benefits for you !

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 130 ER |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1300 x 920 |

|---|---|

| Min sheet size | 580 x 450 |

Accessories

- Feeder

- Feed table with front register control

- Feed table with pull lay operator side

- Pile feeder with automatic lateral moving

- Non-stop on feeder with swords

- Feed table with transport equipment for paper and solid board from 90 to 1000 g / m2

- Feed table with pull lay operator opposite side

- Platin

- Die-Cutting platin with 1 cutting plate 5 mm

- Micrometric adjusting system

- 1 more die chase closed bottom for the platin

- Diecutting platen with a die-cutting chase (fixed bottom plate)

- Stripping Station

- 1 die-cutting upper stripping frame

- Automatic trimming extraction station with no. 2 lower stripping frame with related equipment

- Blanking Station

- Universal lower tool for blanket

- Delivery

- Pile output delivery in separate poses with no. 1 Universal lower tool

- Pile output delivery in separate poses with no. 2 upper pull-out frames

- Pile output delivery in separate poses with non-stop grid and automatic pile change device

- Various

- Platform

- Main Motor

- Electrical cabinet

- Elevated 350 mm

- All books, electrical scheme, manual instruction books, spare parts books and standard tools

- Oil cooling unit

Machine overview

| Year | 1985 |

|---|---|

| Serial Number | 057700302 |

| N.of working hours | 73000 |

“EXTRA” Accessories Overview

- Die-Cutting platin with 1 cutting plate 5 mm

- Micrometric adjusting system

- 1 more die chase closed bottom for the platin

- Automatic trimming extraction station with no. 2 lower stripping frame with related equipment

- Elevated 350 mm

- Oil cooling unit

Reference Overview

| Reference | 21036037 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

Note:

Fully Cleaned and painted

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset