Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

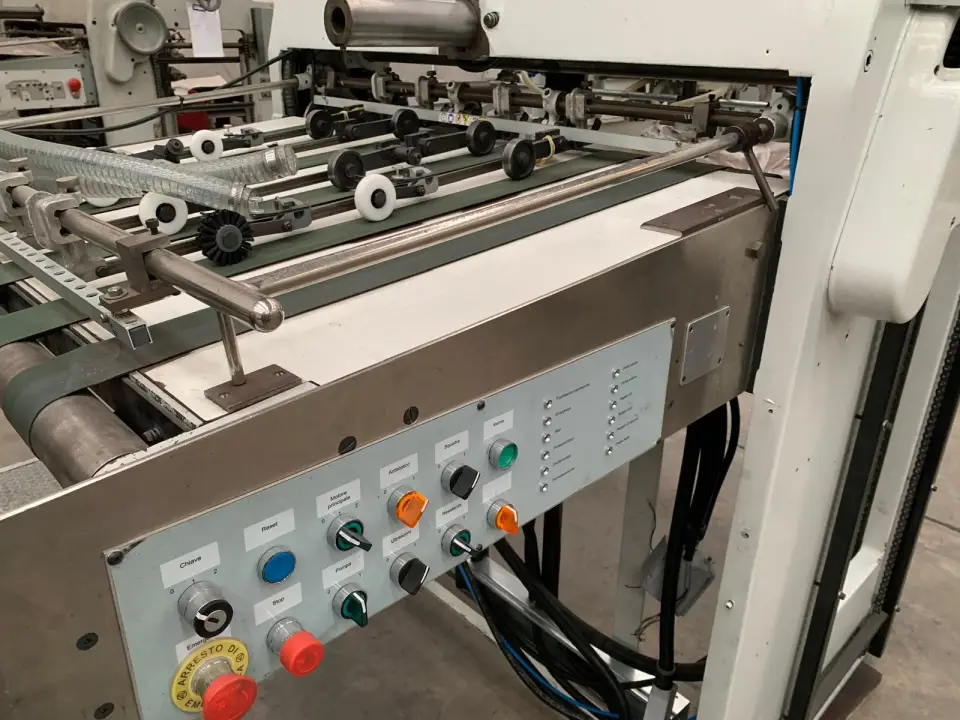

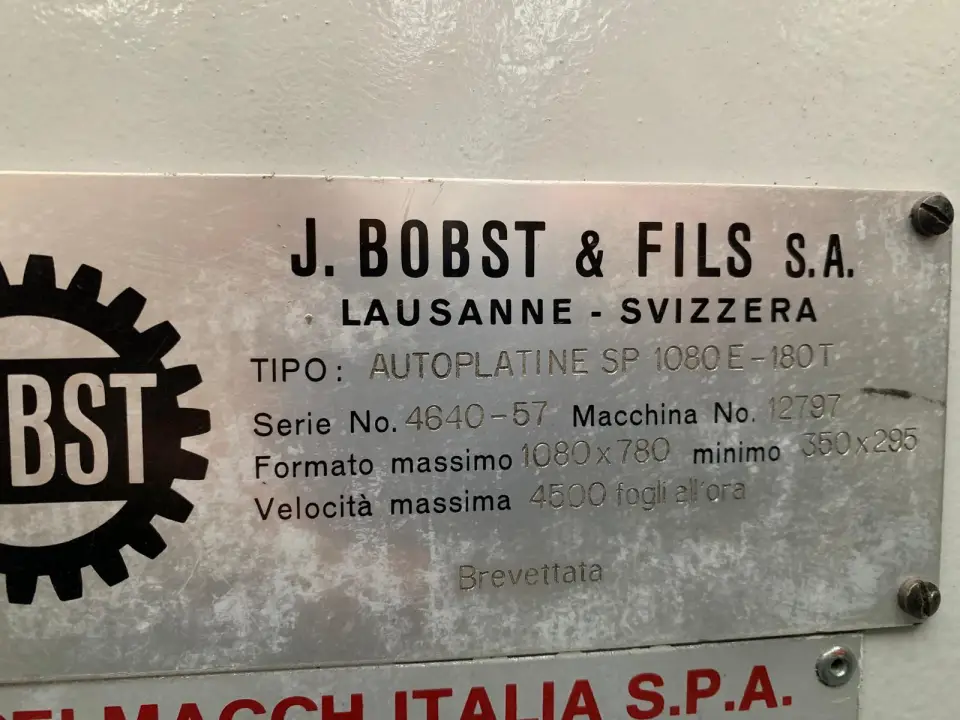

Bobst SP 1080 E

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 1080 E |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 780 x 1080 mm |

|---|---|

| Min sheet size | 295 x 350 mm |

Accessories

- Feeder

- ULTRASONIC DOUBLE SHEET DEVICE

- Stripping Station

- STRIPPING STATION

- Various

- MACHINE FOR PVC AND PLASTIC MATERIAL DIE-CUTTING

- IONIZATORS DEVICE

- ALL NEW ELECTRONIC SYSTEM

- HOT DEVICE ON THE SHEET

- 180 Ton

- 4.500 speed/hour

Machine overview

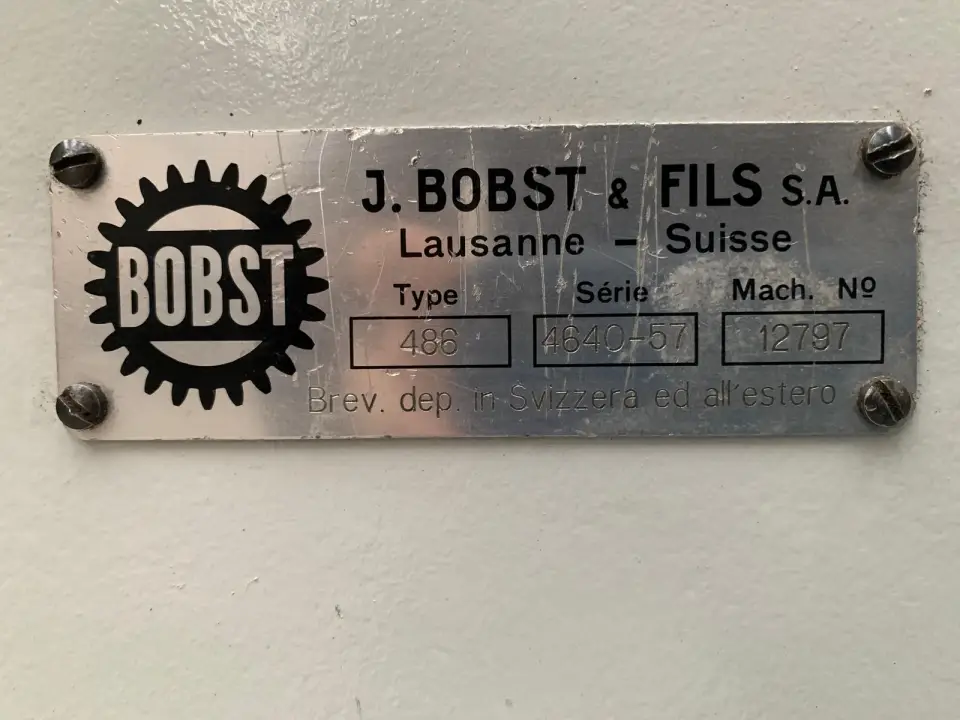

| Serial Number | 4640-57 |

|---|

“EXTRA” Accessories Overview

- ULTRASONIC DOUBLE SHEET DEVICE

- MACHINE FOR PVC AND PLASTIC MATERIAL DIE-CUTTING

- IONIZATORS DEVICE

- ALL NEW ELECTRONIC SYSTEM

- HOT DEVICE ON THE SHEET

Reference Overview

| Reference | 25036489 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset