Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

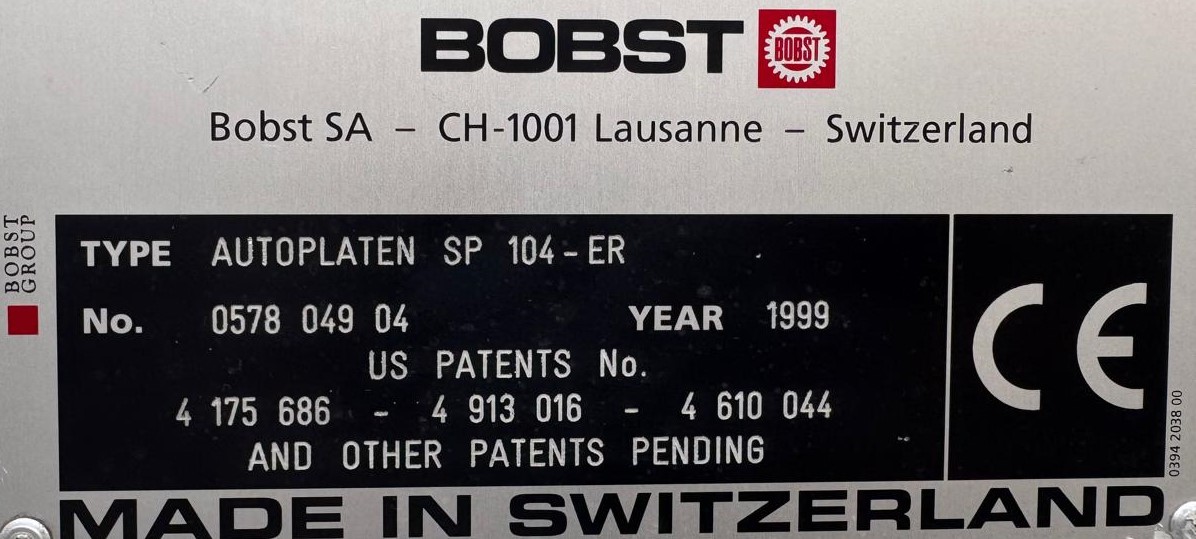

Bobst SP 104 ER

Yes, Bobst is a well-known leader in the die-cutting industry, providing innovative machinery solutions for packaging production. Over the years, Bobst has continued to enhance its die-cutting technology, focusing on improving efficiency, precision, and productivity. One notable development in their offerings is the inclusion of blanking stations in their die-cutting machines.

A blanking station is an important feature that automatically separates the die-cut products (such as cardboard or paperboard blanks) from the waste, creating a clean, efficient process for high-volume production. The addition of blanking stations to die-cutting machines is part of a broader industry trend towards automation and streamlining workflows, reducing manual labour, and improving overall production efficiency.

By integrating blanking stations, Bobst is meeting the growing demand for more automated, faster, and efficient solutions, especially in industries like packaging and printing where time and precision are crucial. This also reflects the increasing focus on reducing material waste, enhancing productivity, and lowering costs for manufacturers, all of which are key competitive advantages in the market.

The move to sell more machines with blanking stations aligns with the industry’s broader push towards automation and smart manufacturing solutions. It helps companies save time, reduce human error, and enhance overall efficiency, while also improving safety on the production floor.

Would you like more details about the specific machines or technologies Bobst is offering with blanking stations? We have a list of benefits for you !

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 104 ER |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1040 x 740 |

|---|---|

| Min sheet size | 350 x 400 |

Accessories

- Machine

- Platform with safety barrier

- Centerline for job quick-change

- Electronic double sheet control

- Adjustable centering at the stripping and at the delivery

- Air conditioning for the electrical cabinet

- Gripper bars

- Main motor with frequency variator

- B-41 ADDITIONAL INTERFACE "CUBE". It includes an additional screen and keyboard located on the feeder, operator side, which facilitate the management of the machine.

- B-1 ELEVATED MACHINE Machine elevated 415 mm, included elevation of the steps

- Feeder

- Pile-tray with handle allowing manual lateral correction of the pile during production

- Photocells for automatic cycle on feeder

- Pile height control at the front edge thanks to a photoelectric cell

- Pile rear guide (OS and OOS sides)

- Adjustable lateral blowers with Centerline references

- Suction unit with multiple adjusting

- Safety system for lowering the pile try

- C-4 NON-STOP FEEDER MANUAL DEVICE

- C-5 CONTROLLABLE SHEET ARRIVAL FOR PERFECT SYNCHRONIZATION OF SHEET ARRIVAL AND REDUCTION OF MACHINE STOPPAGES

- C-8 VERTICAL POSITIONING OF THE SUCTION UNIT. Eliminates manual interventions to compensate for the flatness of the pile shape

- Introduction table

- Covered with an anti-static stainless steel plate

- Synchronization of the sheet adjustable at the stop, allows to adapt the speed of the feeder with which of the platin

- Imput on table feeder

- 4 front lays, adjustable in pairs with front register control

- Pull-lay operator side (OS) adjustable according to Centerline, with sheet control

- Double sheet detector

- Support plates at entry of platen station

- Sheet-hold down device (guiding the sheets to front lays)

- Upper frame with manual lifting device

- Upper sheet transport equipment for paper, cardbord and corrugate cardboard to 4 mm thickness

- Transport belt With lateral guidance and automatic tension system

- D-73 FEED BELT SLOW-DOWN DEVICE Ensures smooth arrival of sheets against the front registers

- D-3 PUSH GUIDE (OOS opposite operator side) WITH ELECTRONIC CONTROL useful for thick carton and corrugate

- Platin

- Grippers re-opening device

- Die-cutting device without band of gripper grip

- Equipment centering and locking

- Locking of the chase against the upper beam

- Measurement of the die-cutting force with strain gauge

- Resocell: synthetic material supporting plate. Thickness 22.5 mm

- 1 Upper chase with quick locking: fixed bottom (E-3) Plate, thickness 2 mm and make-ready protection plate of syntetic material, 1 mm thickness

- 1 Cutting plate (E-4)

- E-5 COMPENSATION PLATE 4 mm thickness. it's useful for thin plate for repetetive work

- E-55 ADJUSTABLE SUPPORTING PLATE CENTERINGS (MICROMETRIC)

- Stripping Station

- 3 drawer frames system with micrometric adjusting

- 1 Upper Stripping Frame (F-2)

- 1 Upper stripping equipment (F-21) required to create a waste stripping tool, including crossbars, clamps, stripper holders and stripping pins of 3, 5 and 10 mm of diameter

- 1 Fastening equipment for stripping die (F-22)

- 1 Central drawer frame (F-71)

- 1 Fastening equipment stripping table (F-75)

- 1 lower pull-out frame (F-8)

- 1 Lower stripping equipment (F-81) Equipment for waste stripping including crossbars, pins and supports

- F-9 PRE-SETTING TABLE : Adjustable. Allows the preparation of a second job during production, reducing machine makeready time and increasing the time available to run production. Requires: a series of supplementary stripping tools

- F-31 1 UPPER PULL-OUT FRAME QUICK LOCK. It reduces stripping tool assembly times; the quick-closing device allows the tool to be changed in the machine)

- B-23 SHEET BRAKING DEVICE USING BERNOULLI SYSTEM AT STRIPPING SECTION. Includes braking tablets that are used with the Bernoulli system. It allows better maintenance of the back part of the sheets of light material

- F-35 1 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- F-72 1 CENTRAL PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT

- F-76 1 FASTENING EQUIPMENT FOR STRIPPING TABLE ON CENTRAL PULL-OUT FRAME QUICK LOCK It allows to equip a stripping table to install it on central pull-out frame quick-lock

- Blanking Station

- Drawer sheet device with electronic control of sheet presence

- Gripper opening device that allows the sheets to arrive in the pile

- Automatic pallet change device (Conveyor) With safety barrier and photoelectric cells (opposite operator side)

- Automatic Non-Stop device

- Safety of pile ascent

- Belt for evacuation of trimmings or residual grid located at the end of the machine. It also allows the removal of a sheet with non-separated poses, for quality control

- Residual grid braking brush

- Drawer frames system with micrometric adjustment

- 1 Upper drawer frame (H-21)

- 1 Universal upper tool (H-25). Equipment necessary for the creation of a pose separation tool

- 1 Fixing material of a separating tool (H-26). For fixing the upper separation tools of fabricated poses. Recommended for repetitive work.

- 1 Bottom drawer frame with fastening material (H-5). Allows you to attach a lower separation tool to manufactured poses

- 1 Adjustable lower tool (H-6). Adjustable tool includes: - universal frame (H-61) - material that allows you to assemble the separation grid

- Delivery

- B-25 BERNOULLI DEVICE AT THE DELIVERY

- Conformity to standards and security

- The Autoplaten Presses SP 104-E is in conformity with the European Directives for the Safety and Health requirements related to its design and construction, sa well American standards UL 508 and NFPA related to industrial equipment

- Emergency Stops

- Operator safety devices

- Gripper Bar Chain Slip Clutch

- Gripper bar chain locking device

- Handling of the diecutting equipment

Machine overview

| Year | 1999 |

|---|---|

| Serial Number | 057804904 |

| N.of working hours | 62000 |

Conditions Overview

“EXTRA” Accessories Overview

- B-41 ADDITIONAL INTERFACE "CUBE". It includes an additional screen and keyboard located on the feeder, operator side, which facilitate the management of the machine.

- B-1 ELEVATED MACHINE Machine elevated 415 mm, included elevation of the steps

- C-4 NON-STOP FEEDER MANUAL DEVICE

- C-5 CONTROLLABLE SHEET ARRIVAL FOR PERFECT SYNCHRONIZATION OF SHEET ARRIVAL AND REDUCTION OF MACHINE STOPPAGES

- C-8 VERTICAL POSITIONING OF THE SUCTION UNIT. Eliminates manual interventions to compensate for the flatness of the pile shape

- D-73 FEED BELT SLOW-DOWN DEVICE Ensures smooth arrival of sheets against the front registers

- D-3 PUSH GUIDE (OOS opposite operator side) WITH ELECTRONIC CONTROL useful for thick carton and corrugate

- E-5 COMPENSATION PLATE 4 mm thickness. it's useful for thin plate for repetetive work

- E-55 ADJUSTABLE SUPPORTING PLATE CENTERINGS (MICROMETRIC)

- F-9 PRE-SETTING TABLE : Adjustable. Allows the preparation of a second job during production, reducing machine makeready time and increasing the time available to run production. Requires: a series of supplementary stripping tools

- F-31 1 UPPER PULL-OUT FRAME QUICK LOCK. It reduces stripping tool assembly times; the quick-closing device allows the tool to be changed in the machine)

- B-23 SHEET BRAKING DEVICE USING BERNOULLI SYSTEM AT STRIPPING SECTION. Includes braking tablets that are used with the Bernoulli system. It allows better maintenance of the back part of the sheets of light material

- F-35 1 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- F-72 1 CENTRAL PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT

- F-76 1 FASTENING EQUIPMENT FOR STRIPPING TABLE ON CENTRAL PULL-OUT FRAME QUICK LOCK It allows to equip a stripping table to install it on central pull-out frame quick-lock

- B-25 BERNOULLI DEVICE AT THE DELIVERY

Reference Overview

| Reference | 19033176 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

Note:

Print test possible with your jobs by appointment

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset