Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

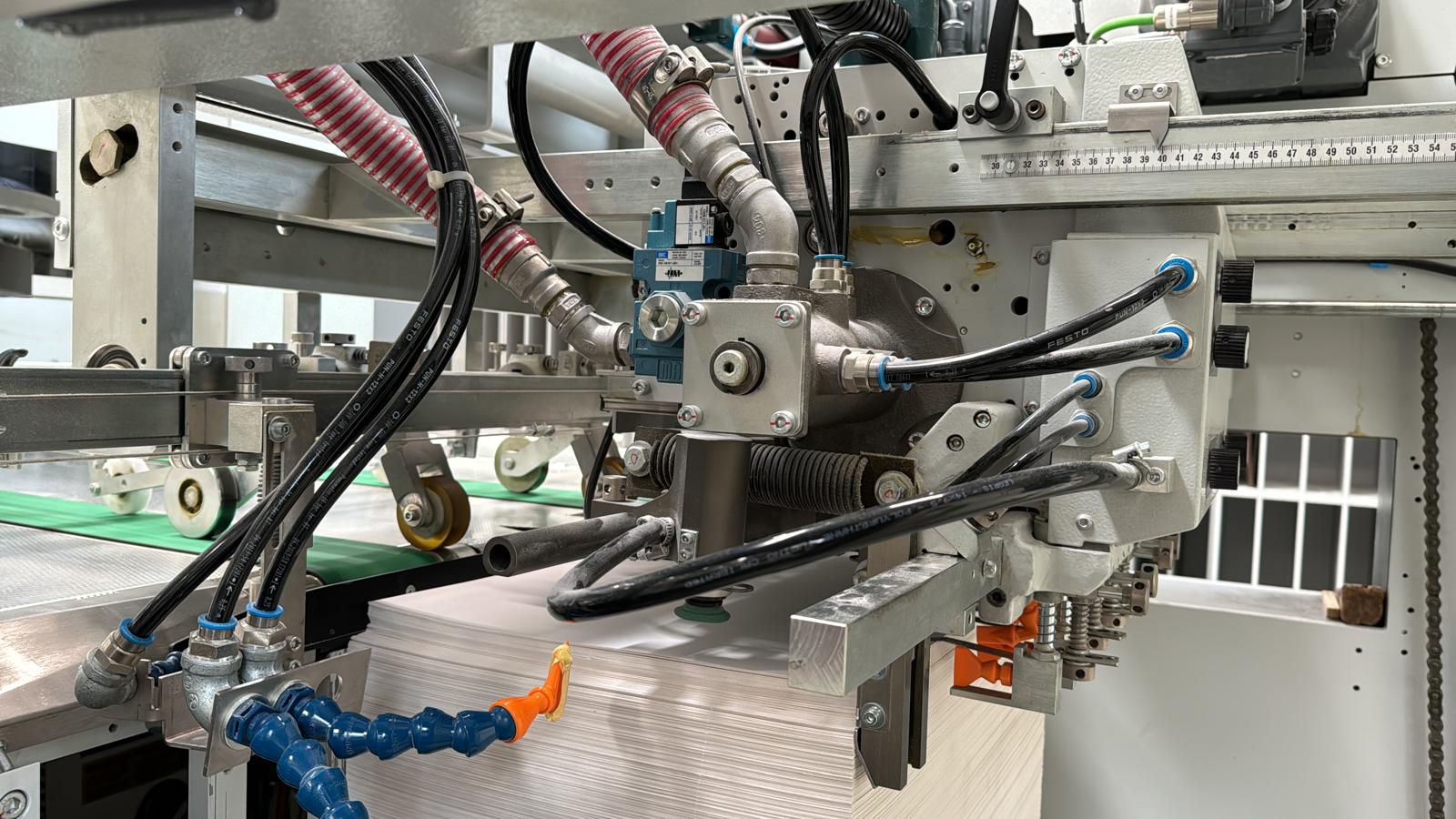

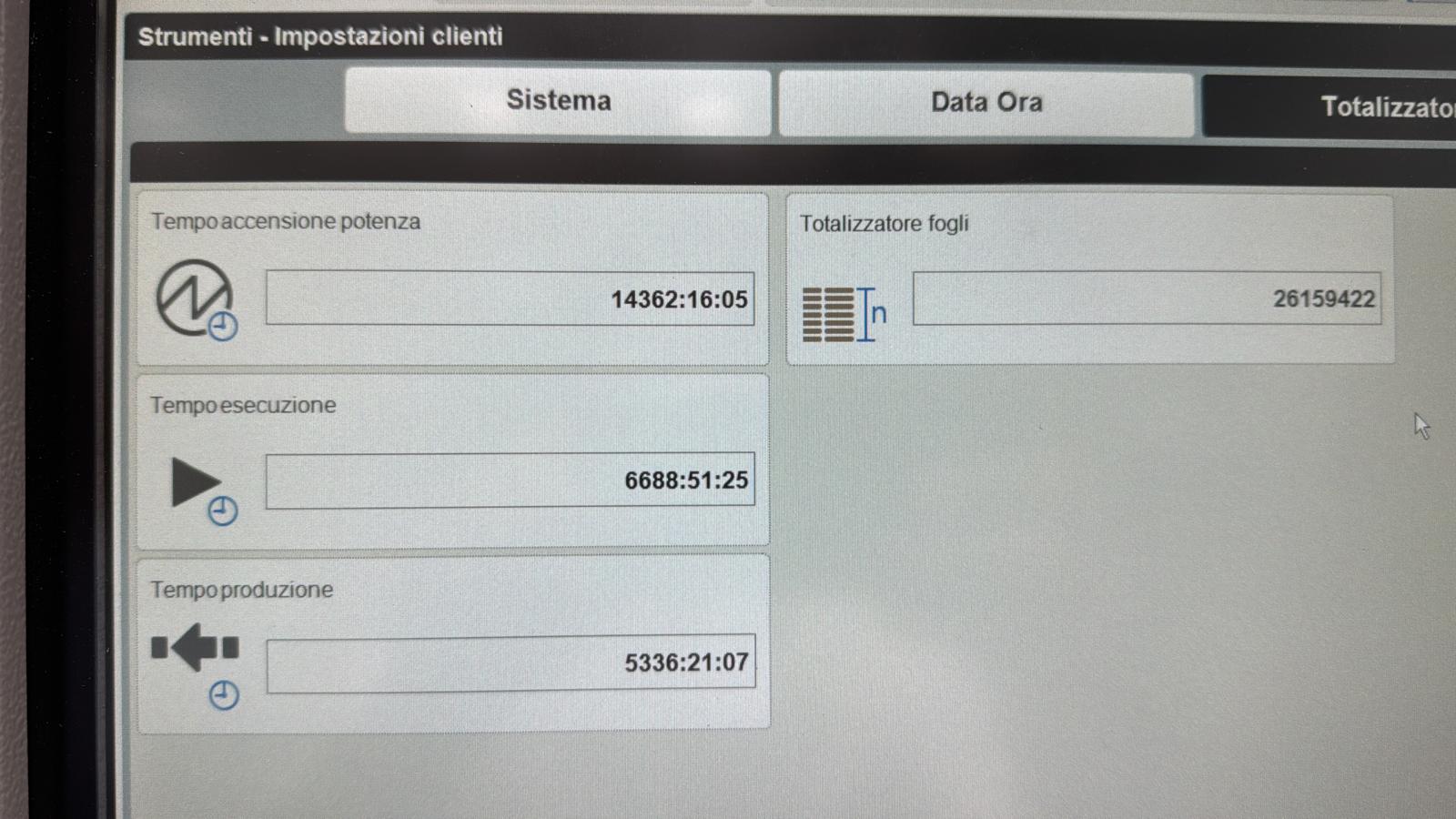

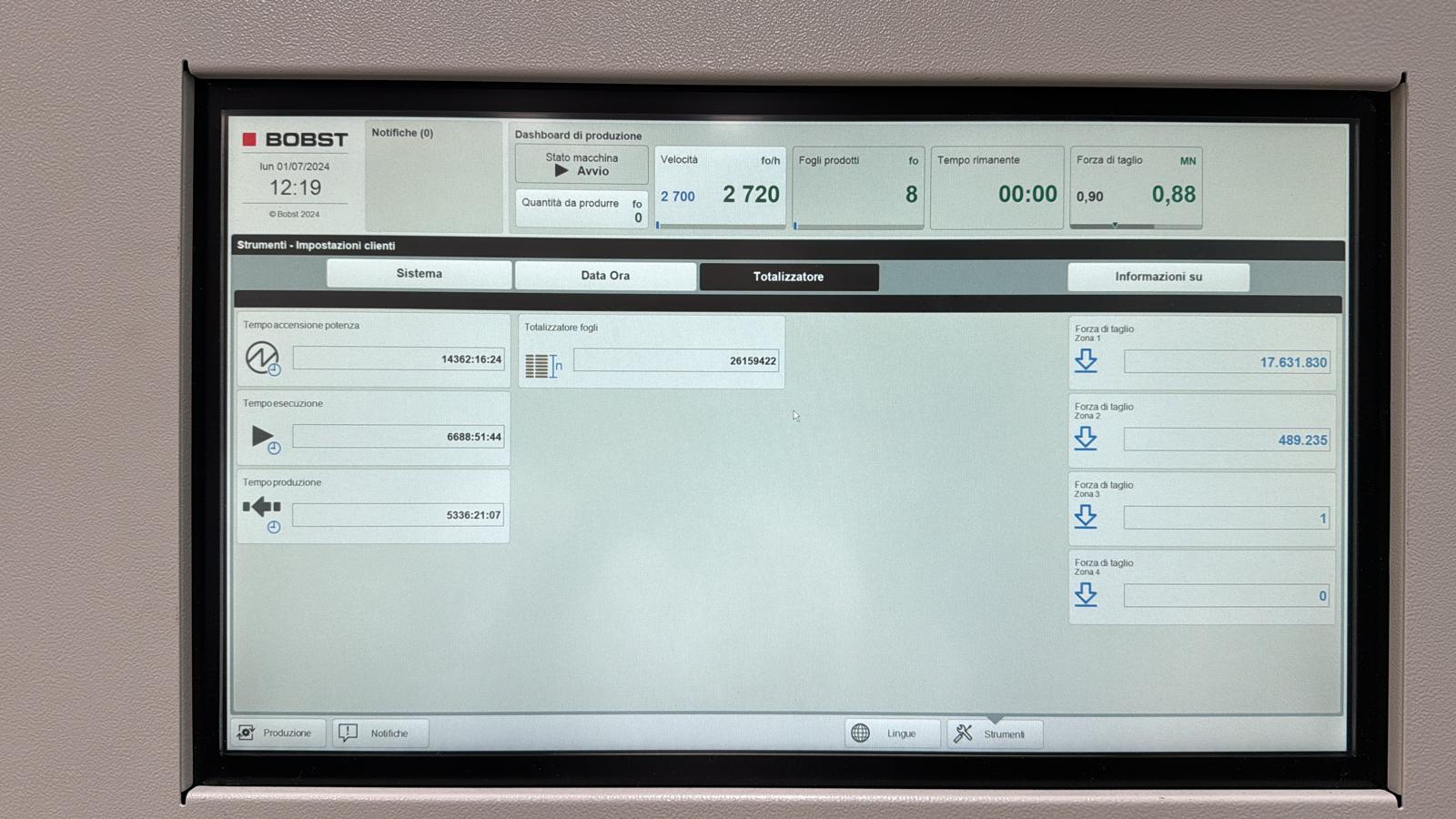

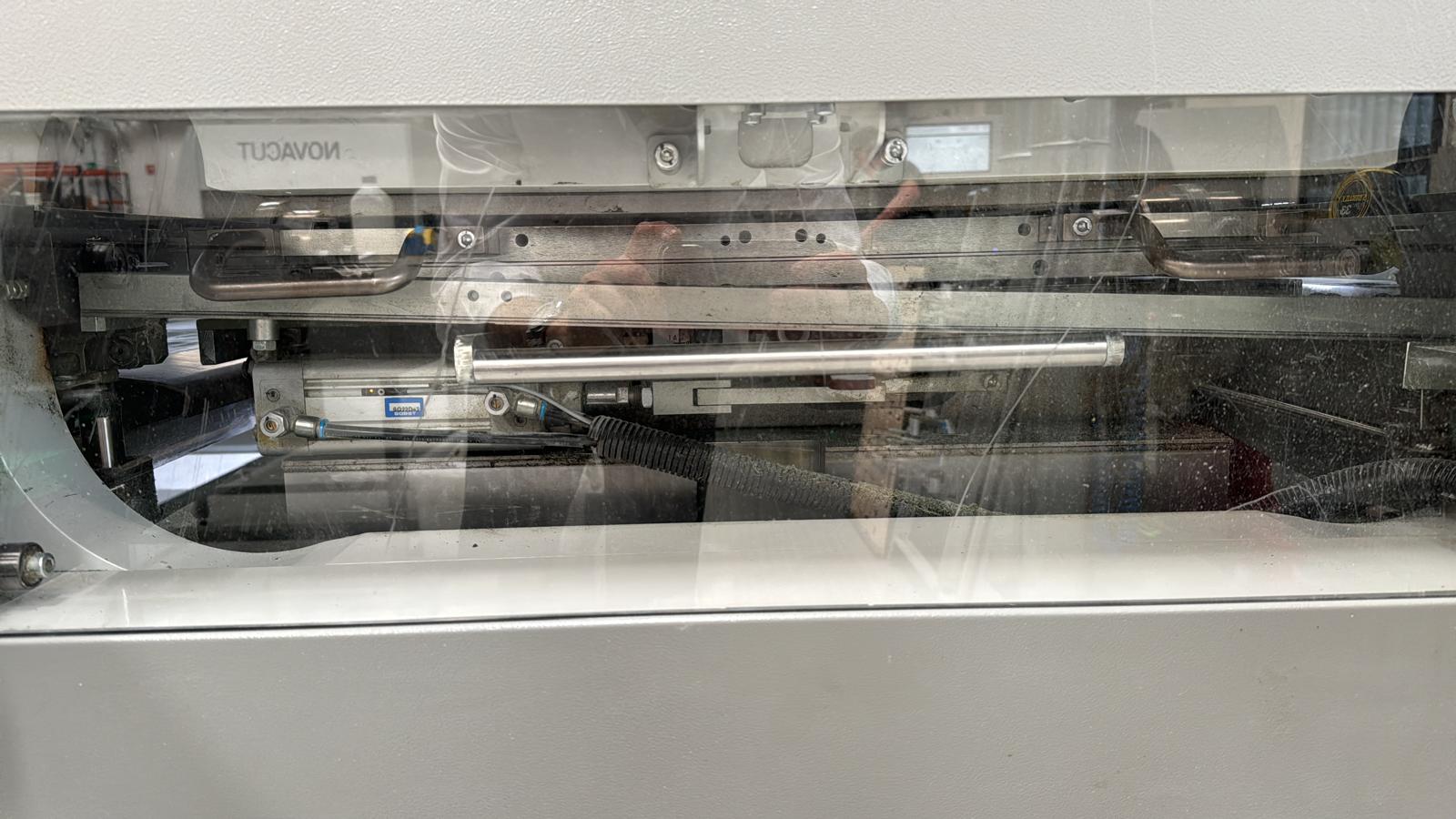

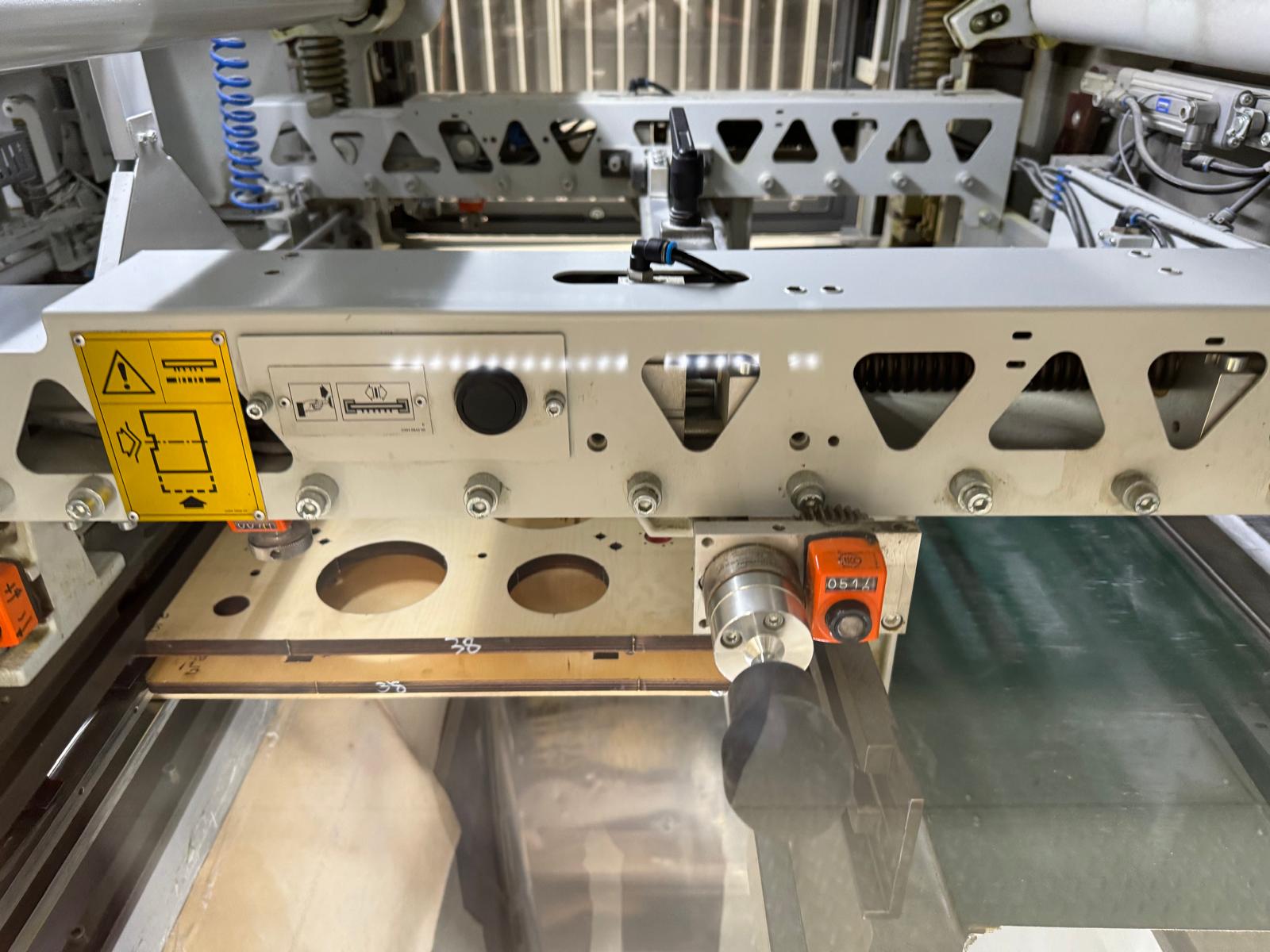

Enlarge Bobst NOVACUT 106E 3.0

| Reference | 24036456 |

|---|---|

| Type | Die Cutting/fustellatrici |

| Manufacturer | Bobst |

| Model | NOVACUT 106E 3.0 |

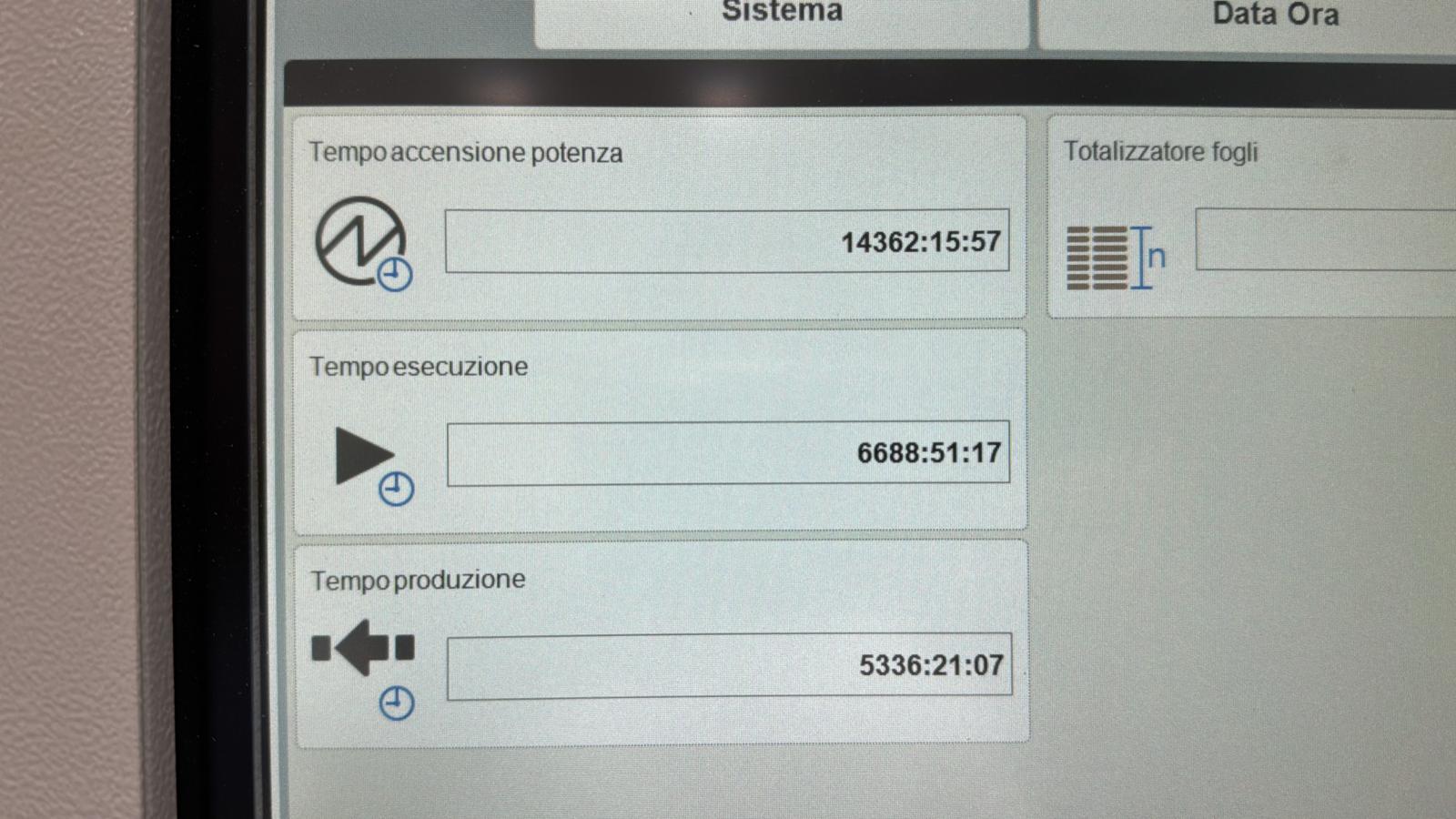

| Year | 2019 |

| Serial Number | BSA05572000479/1940 |

| N.of Impressions | 26 |

DETAILS

| Visible | In production |

|---|---|

| Availability | 01/02/2025 |

| Max sheet size | 1060 X 740 mm |

| Min sheet size | 400 x 740 mm |

Accessories

- Pile tray wit handle allowing manul lateral correction of the pile during production

- Pile lifting controlled by pressfoot

- Synchronization device timing the sheet arrival against the front lays when the machine is at a standstill

- Real pile guides (OS and OOS)

- Side blowers adjustable with Centerline marks

- Suction unit

- Safety system for lowering the pile tray

- Feed table covered with an anti-static stainless steel plate

- Feed table inlet equipped with lateral ramps

- Feed table with support plates at entry of platen station

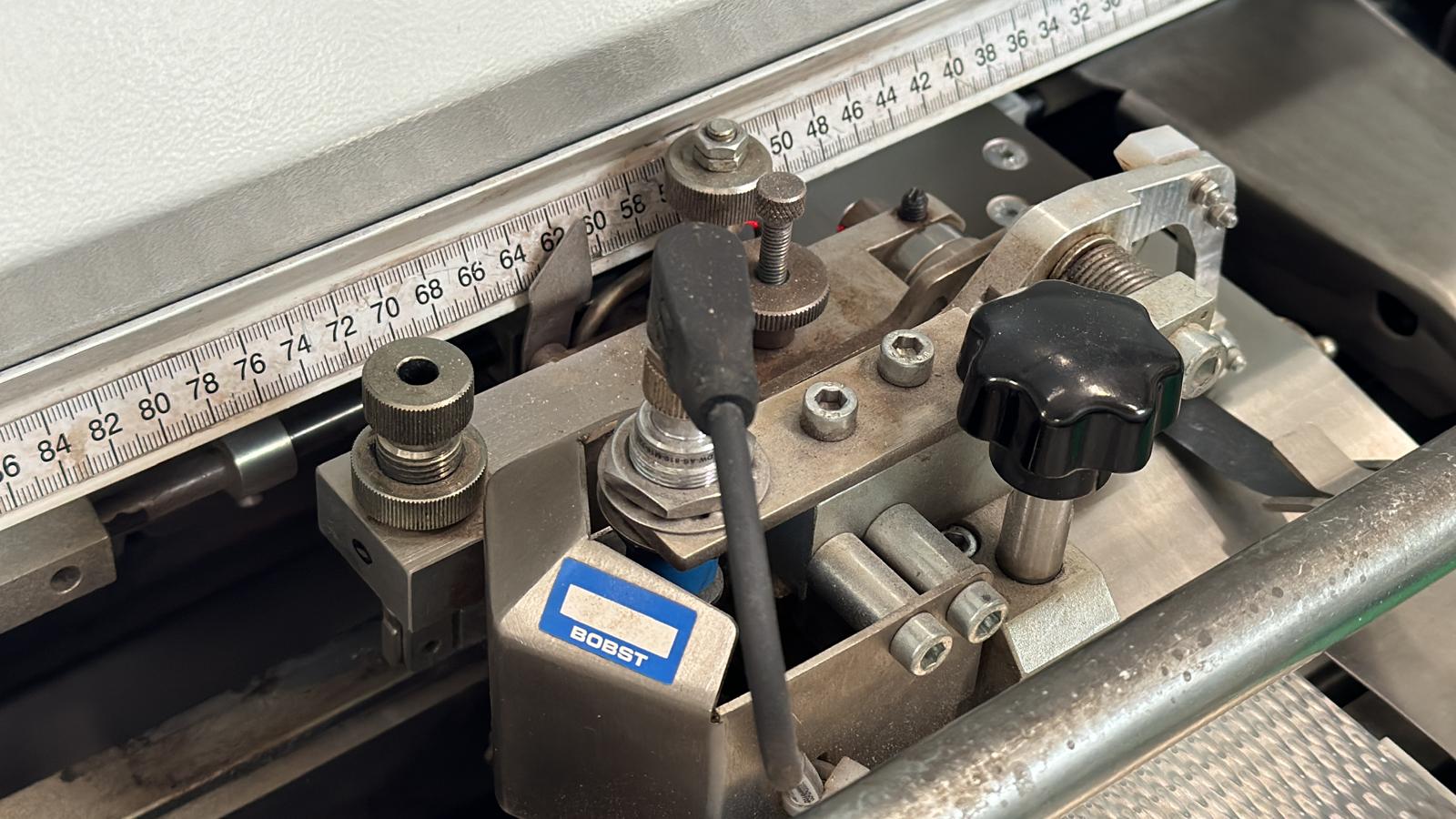

- Feed table with 4 front lays, adjustable in pairs with front register control

- Feed table with Pull guide (OS) adjustable according to Centerline marks, with side register control

- Feed table with double sheet detector. Mechanical, integrated on pull guide (OS)

- Feed table sheet-hold down device (guiding the sheets to front lays)

- Table feeder with upper frame with manual lifting device

- Feed Table with upper transport equipment for paper, paperboard and corrugated board

- Feed table with transport belts (with lateral guidance and automatic tensionning system)

- Pull lay operator side

- 1 D-100.002 Pull Guide (OOS) With side register control. Pull guide adjustable according to the Centerline marks. For jobs with opposite operator side registering.

- 1 D-120.002 Push Guide (OOS) Without mechanical stop (OS). Set of parts for changing a (OOS) pull guide into a push guide.

- Gripper reopening device

- Equipment centering and locking on platin

- Automatic locking of the chase against the upper beam on platen

- Measurement of the cutting force with strain gauge on platen

- Synthetic material supporting plate on platen (Thickness 23.5 mm (0,925)

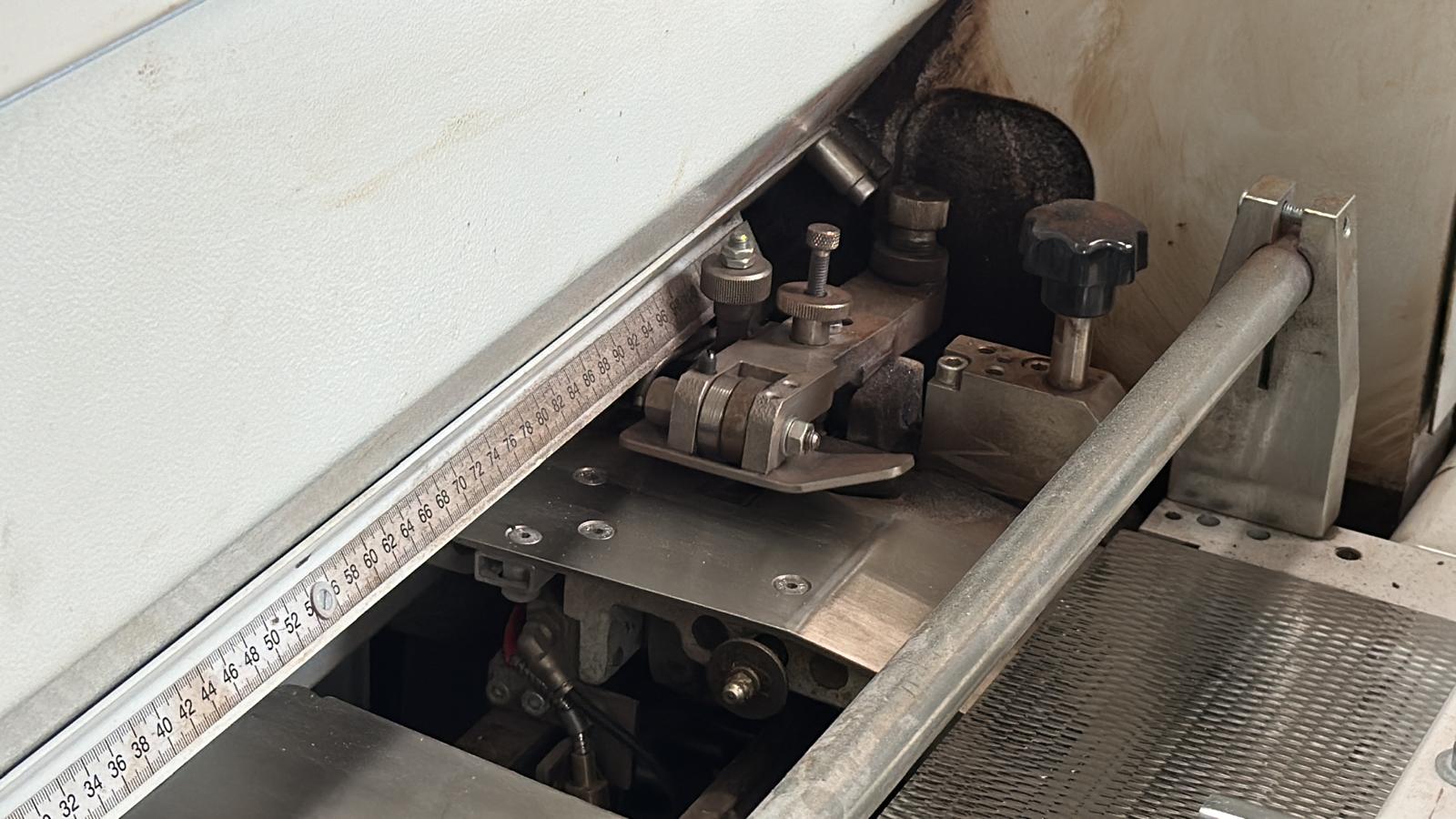

- Adjustable centering at stripping station

- Quick locking device of the central stripping board on Waste Stripping Station

- Motorized lifting of the upper frame on Waste Stripping Station

- Pile tray in delivery

- Front jogger in delivery

- Adjustable rear and side joggers with Centerline marks in delivery

- Braking Brush in delivery

- Non-stop delivery with grill

- Centerline system for quick job changeover

- Bobst-Electronic machine operating system CUBE 3 (Control Unit Bost Electronic) with color touch screen

- Electronic device for sheet travel control

- Control cabinet cooling unit

- Main motor with frequency converter control

- 1 Cutting plate (T-120.001) Thickness 5 mm

- 1 Upper stripping equipment (T-205.001) Equipment required to create a waste stripping tool, including crossbars, clamps, stripper holders and stripping pins of 3, 5 and 10 mm of diameter

- 1 Upper stripping pull-out frame (T-200.001)

- 1 Fastening equipment for stripping die (T-205.002) Including crossbars and clamps

- 1 Adaption material for stripping board on the central frame (quick locking) (T-225.002)

- 1 Lower stripping pull-out frame (T.230.001)

- 1 Lower stripping equipment (T-235.001) Equipment for waste stripping including crossbars, pins and supports

- 1 C-111-001 Manual Non-Stop device

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset