Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

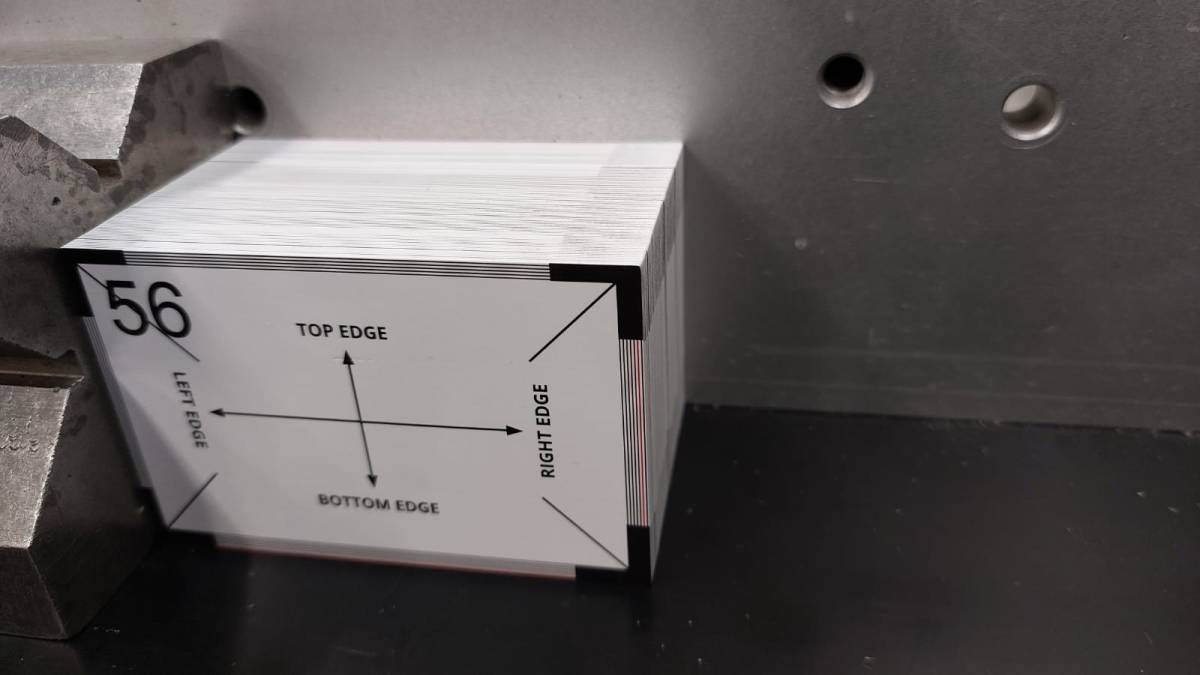

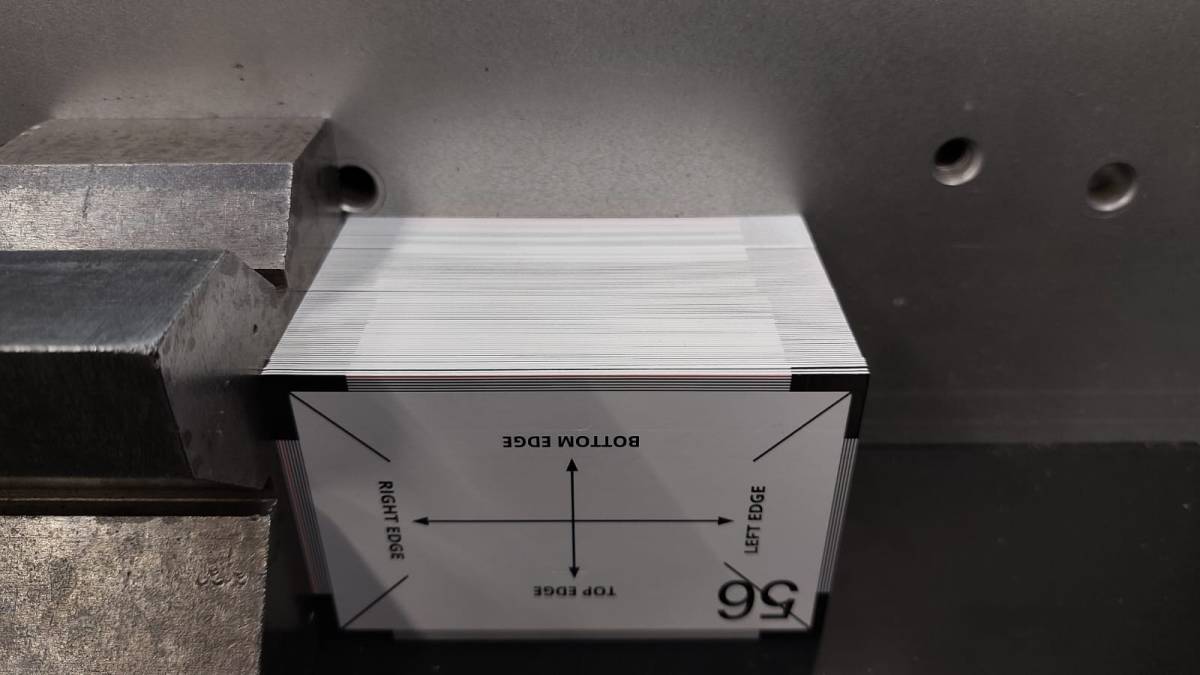

Enlarge

Enlarge

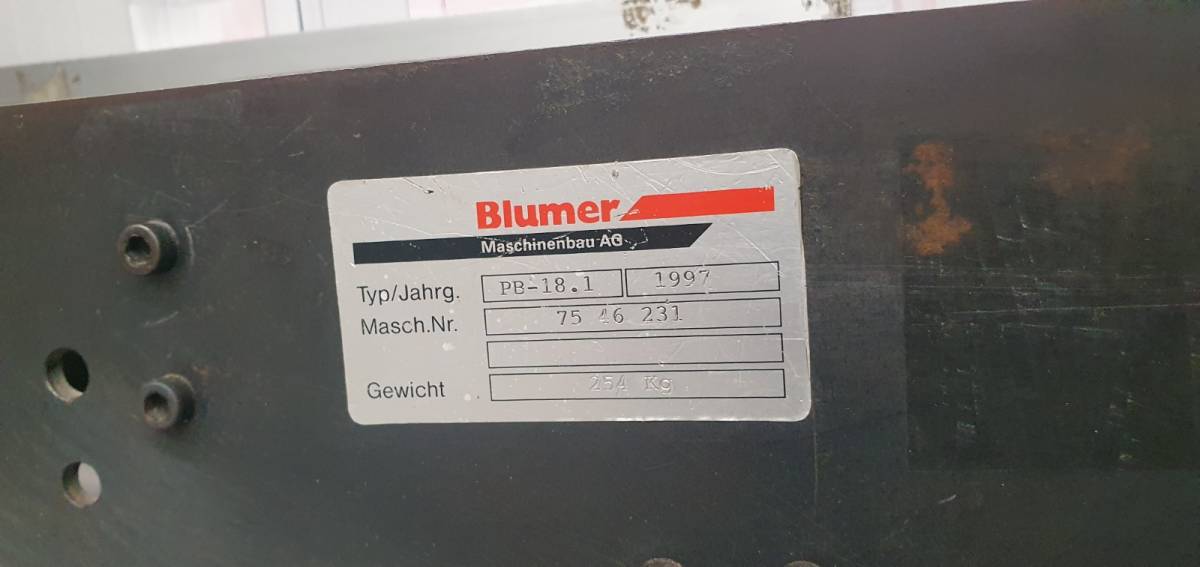

BLUMER ATLAS 110 PB18.1

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | BLUMER |

|---|---|

| Model | ATLAS 110 PB18.1 |

| Type | Die Cutting/fustellatrici |

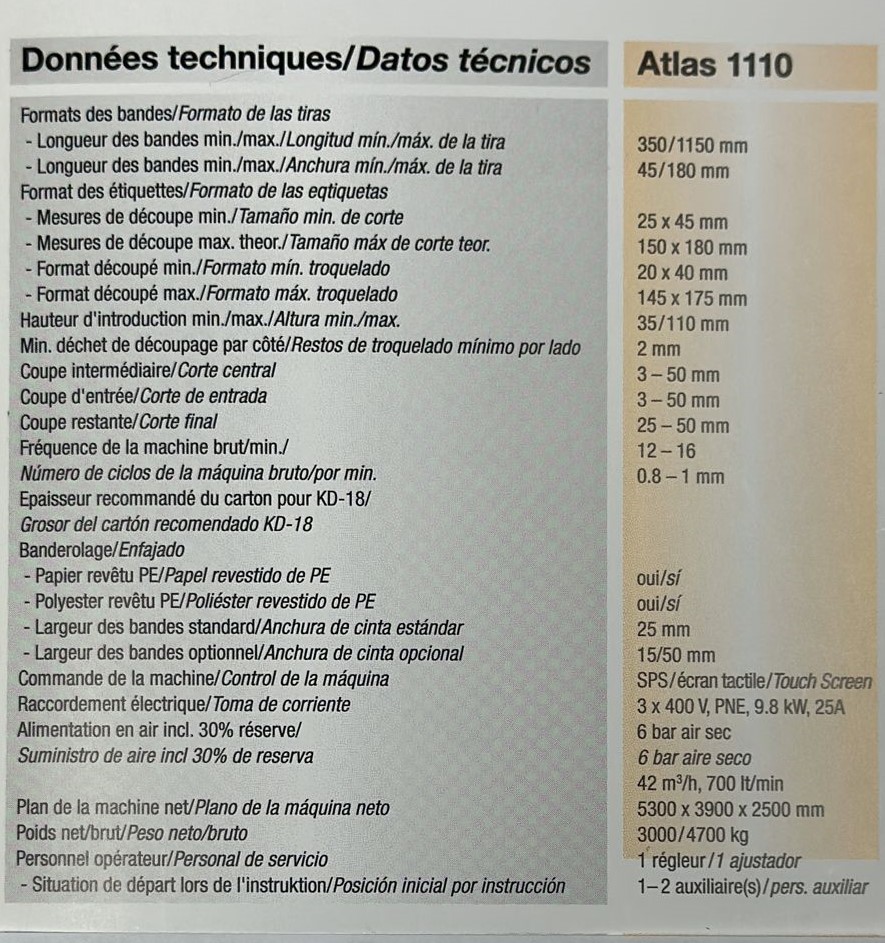

TECHNICAL DATA

| Max sheet size | 110 |

|---|

Accessories

- Printing Units

- D-18 Die-Cutting punching device

- SE-18.2 Infeed and cross cutter with programm

- ST-18.2 Strip stack infeed unit

- Delivery

- PB-18.1 Horizontal and vertical banding unit with delivery

Machine overview

| Year | 1997 |

|---|---|

| Serial Number | 7546231 |

“EXTRA” Accessories Overview

- D-18 Die-Cutting punching device

- SE-18.2 Infeed and cross cutter with programm

- ST-18.2 Strip stack infeed unit

- PB-18.1 Horizontal and vertical banding unit with delivery

Reference Overview

| Reference | 22036204 |

|---|---|

| Visible | Stock |

| Availability | Immediately |

Note:

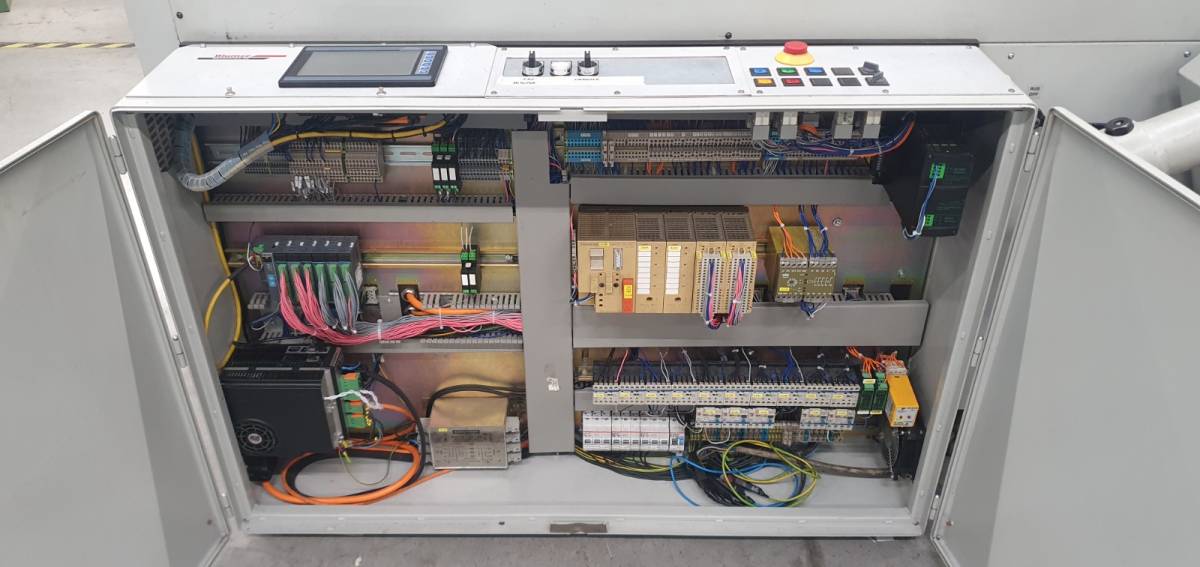

The machine is cleaned and fully checked, NEW PLC with NEW BRUSHLESS MOTOR, NEW SOFTWARE , NEW COLOR TOUCH SCREEN to insert working data, the machine can be tested in production in our workshop.

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset