Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

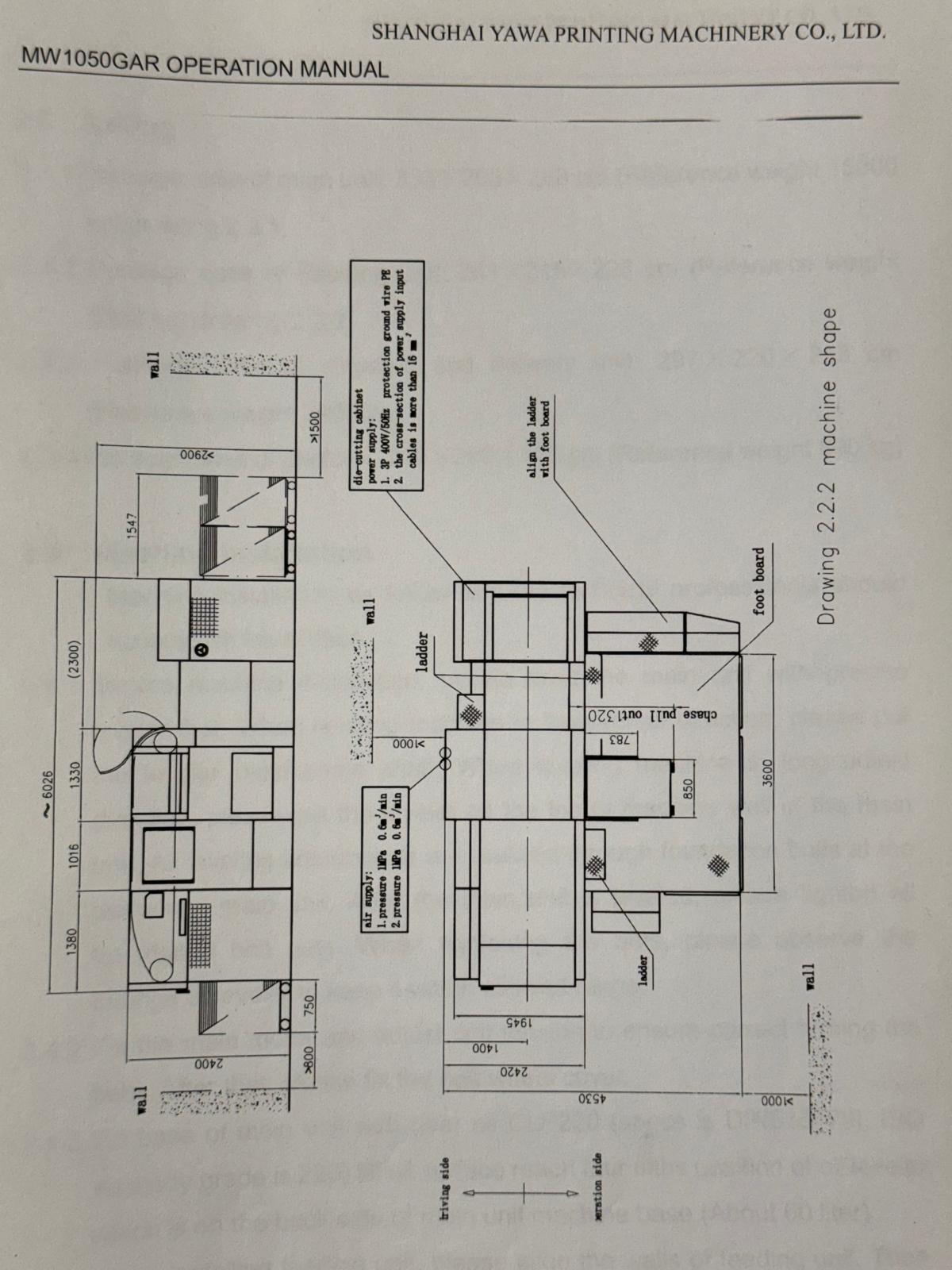

YAWA MW 1050 G

The machine was selected and carefully inspected by our engineers prior to purchase.

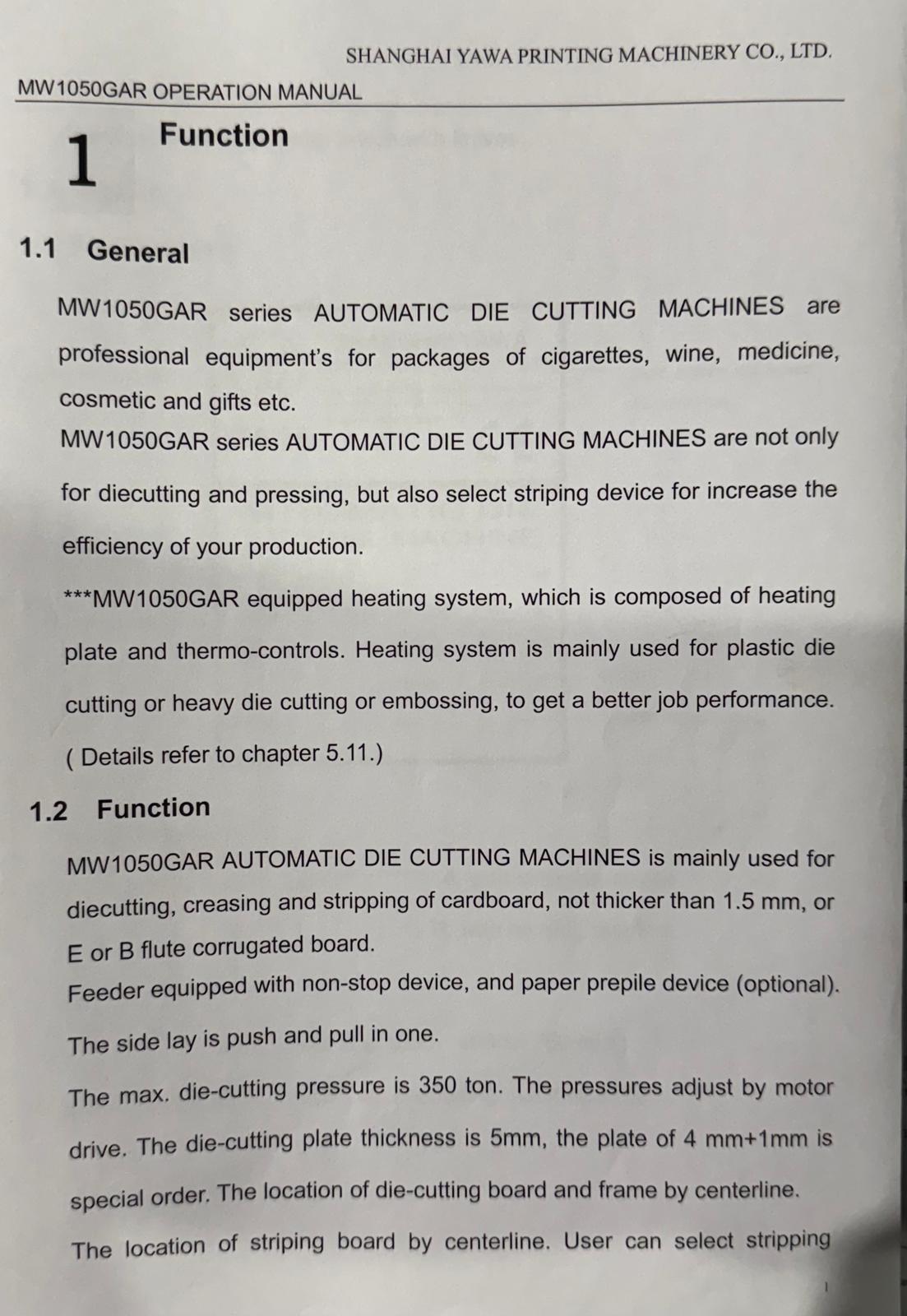

MACHINE SPECIFICATION

| Manufacturer | YAWA |

|---|---|

| Model | MW 1050 G |

| Type | Die Cutting/fustellatrici |

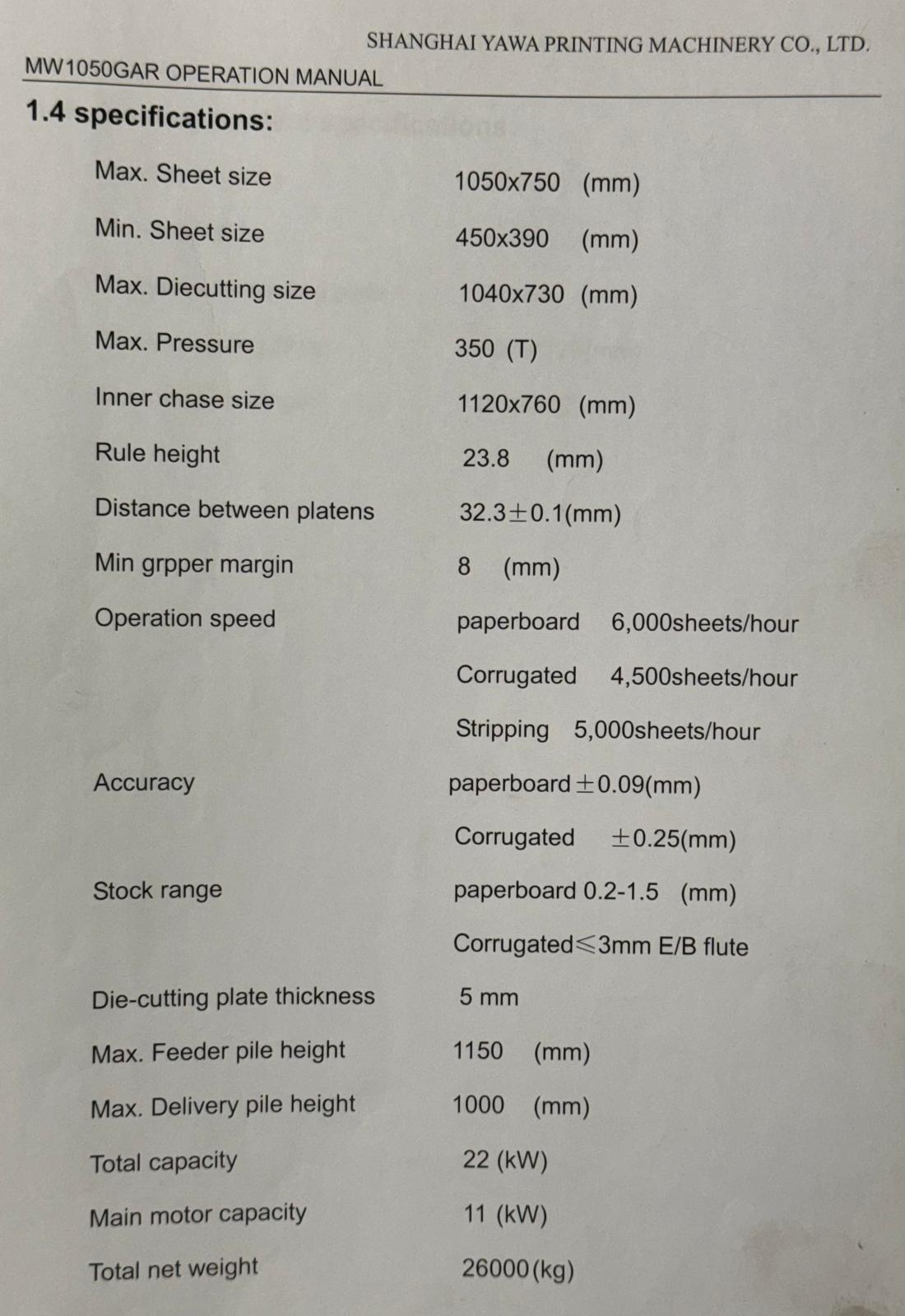

TECHNICAL DATA

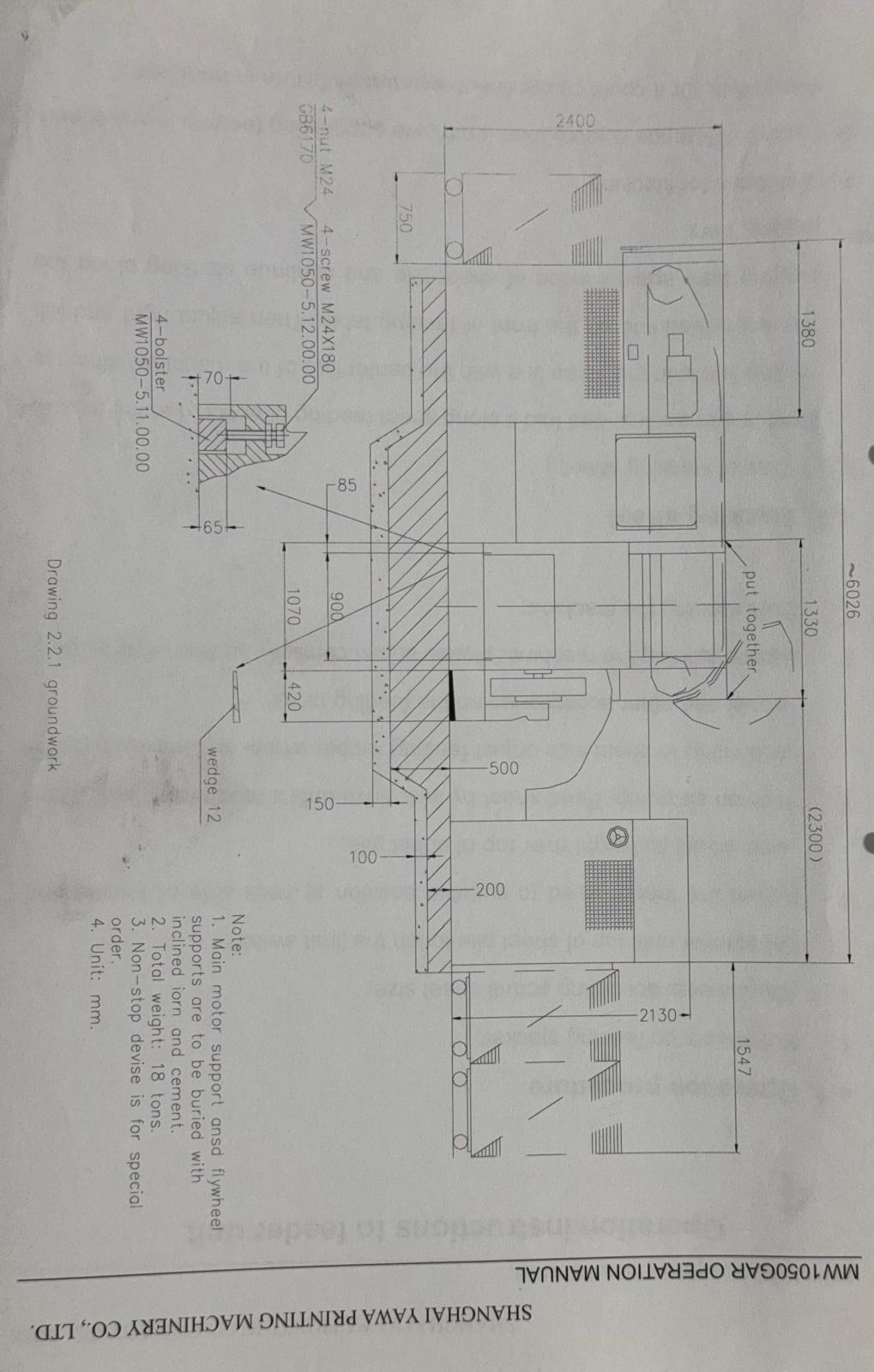

| Max sheet size | 1050 x 750 |

|---|

Accessories

- Feeder

- Additional blowers for papaer

- Photocells for sheet travel control for synthetic material

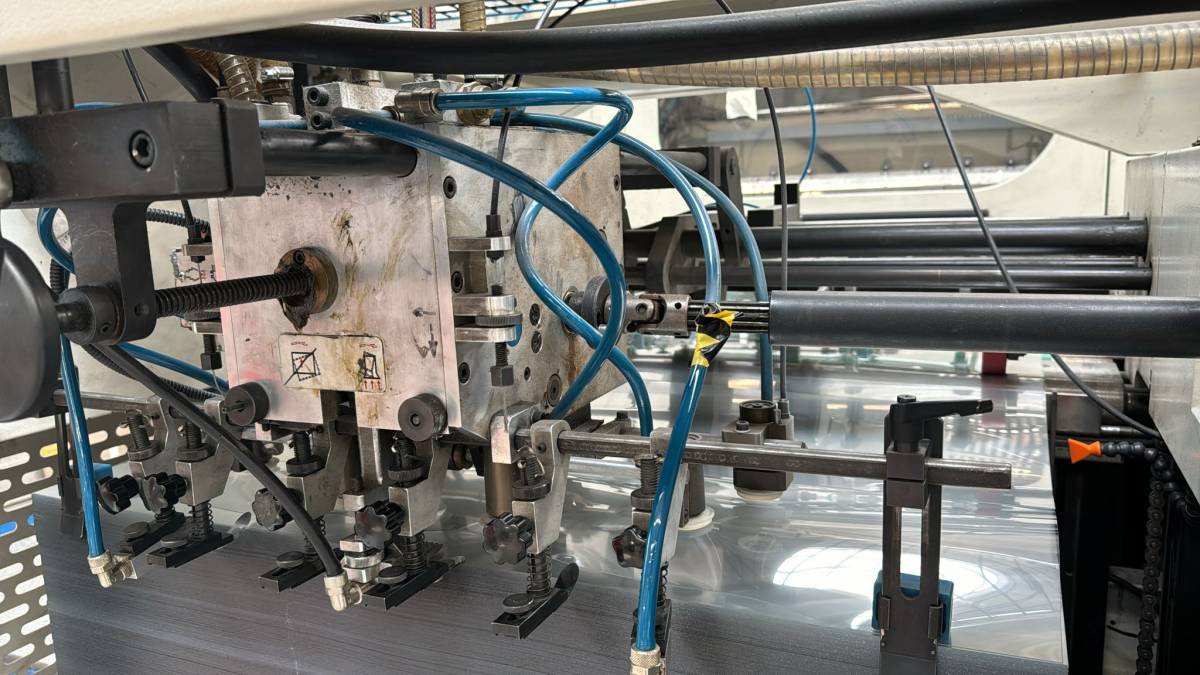

- Stripping Station

- Stripping

- Upper pull-out frame quick lock

- Nr 2 Upper pull-out quick lock frames

- Nr 4 lower stripping frame for needles

- Delivery

- NON-STOP conveyor in the delivery

- Various

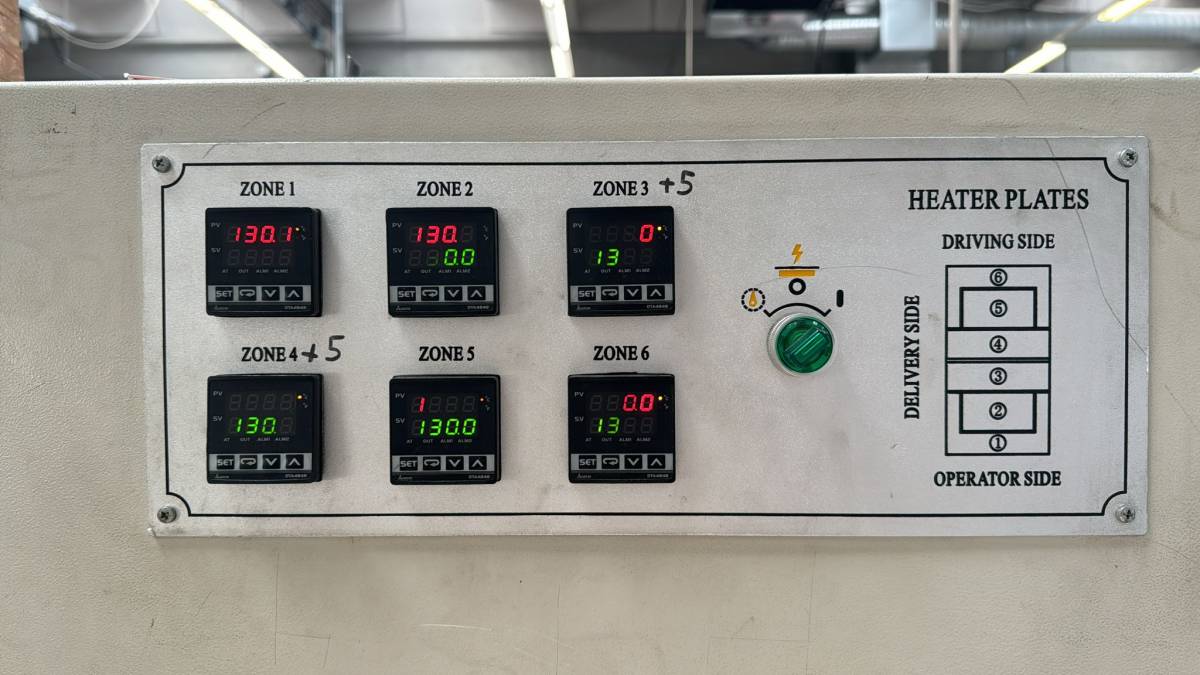

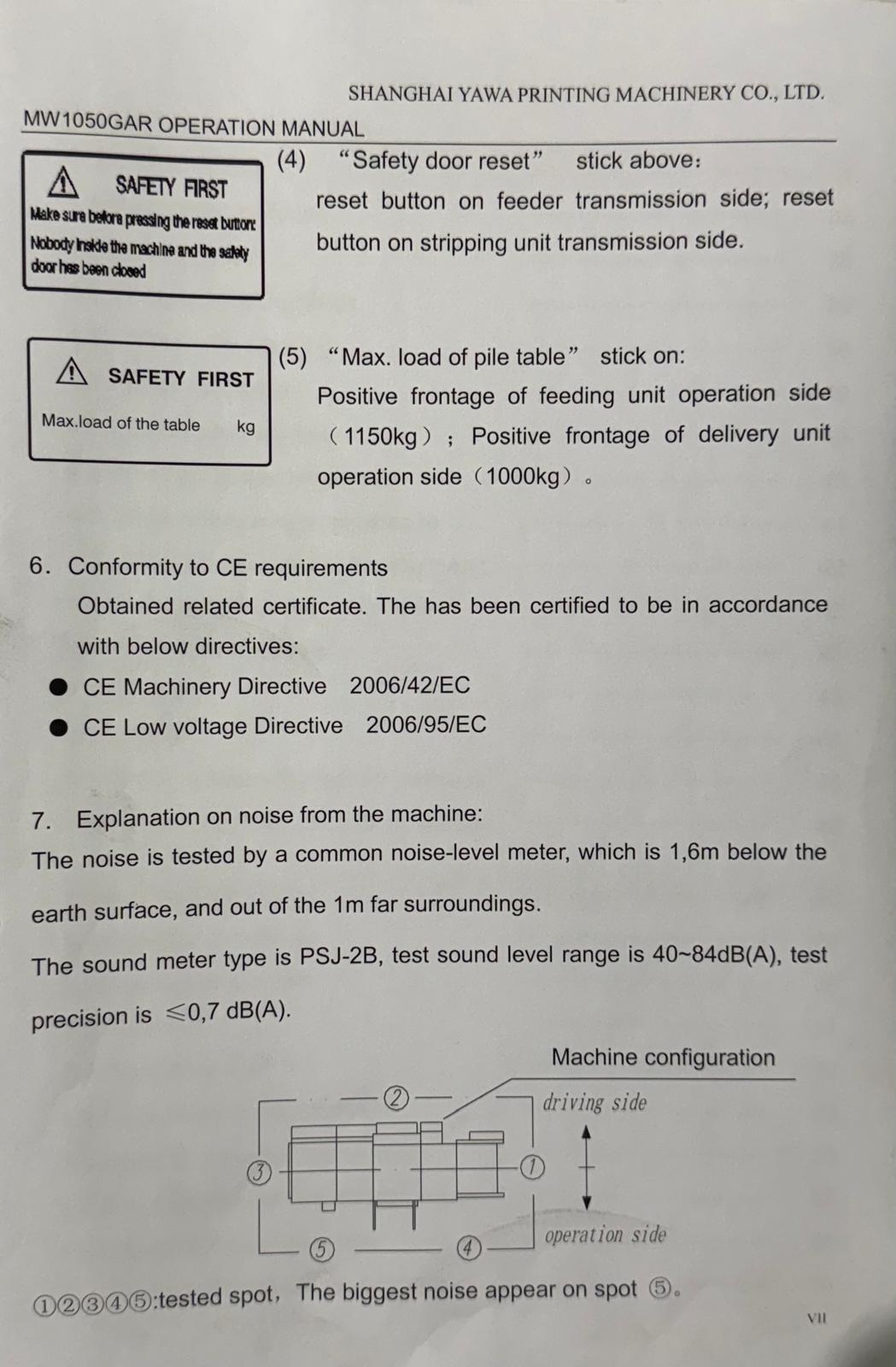

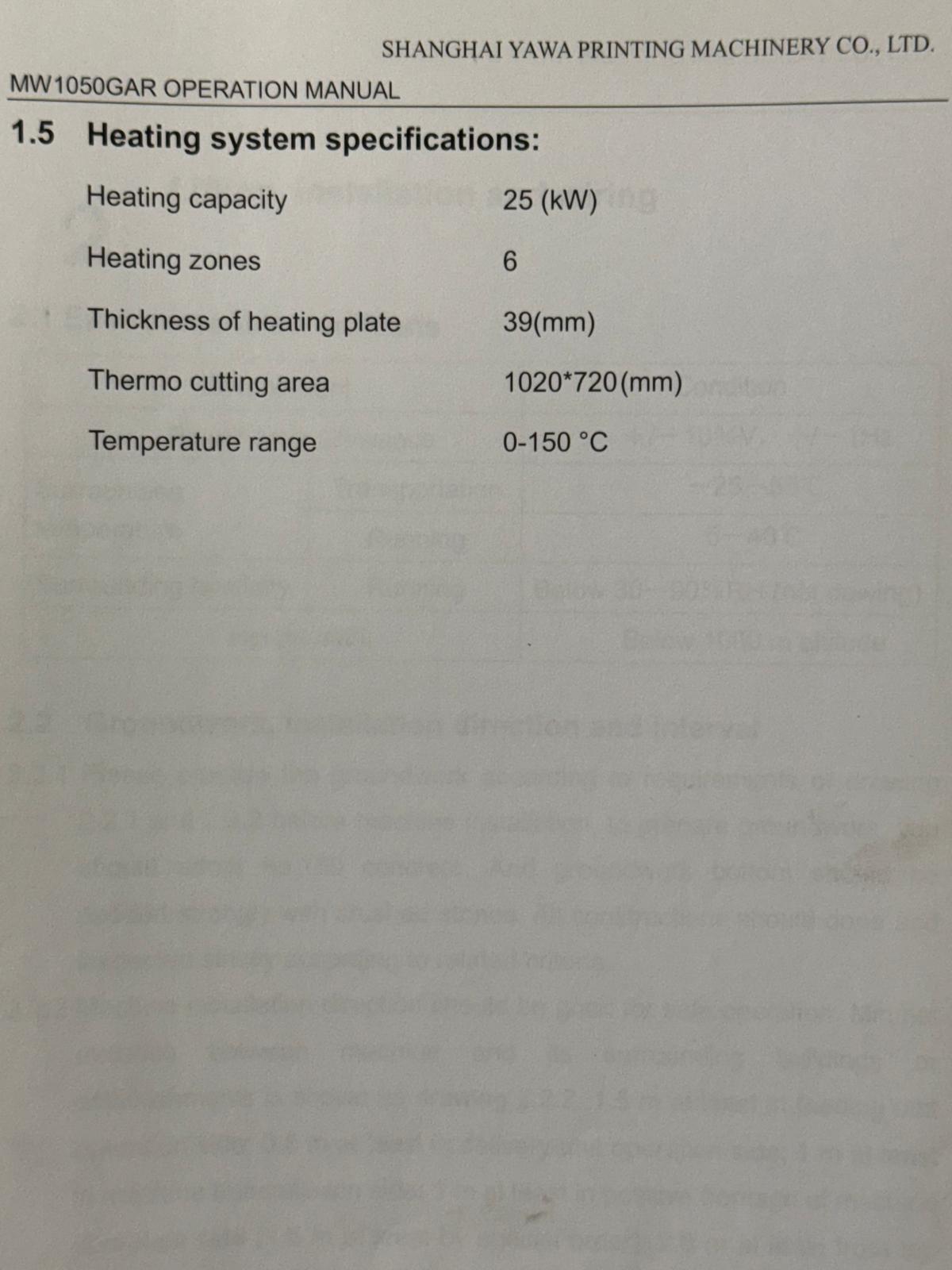

- 60 / 5.000 Die cutting machine with heated plate for synthetic materials

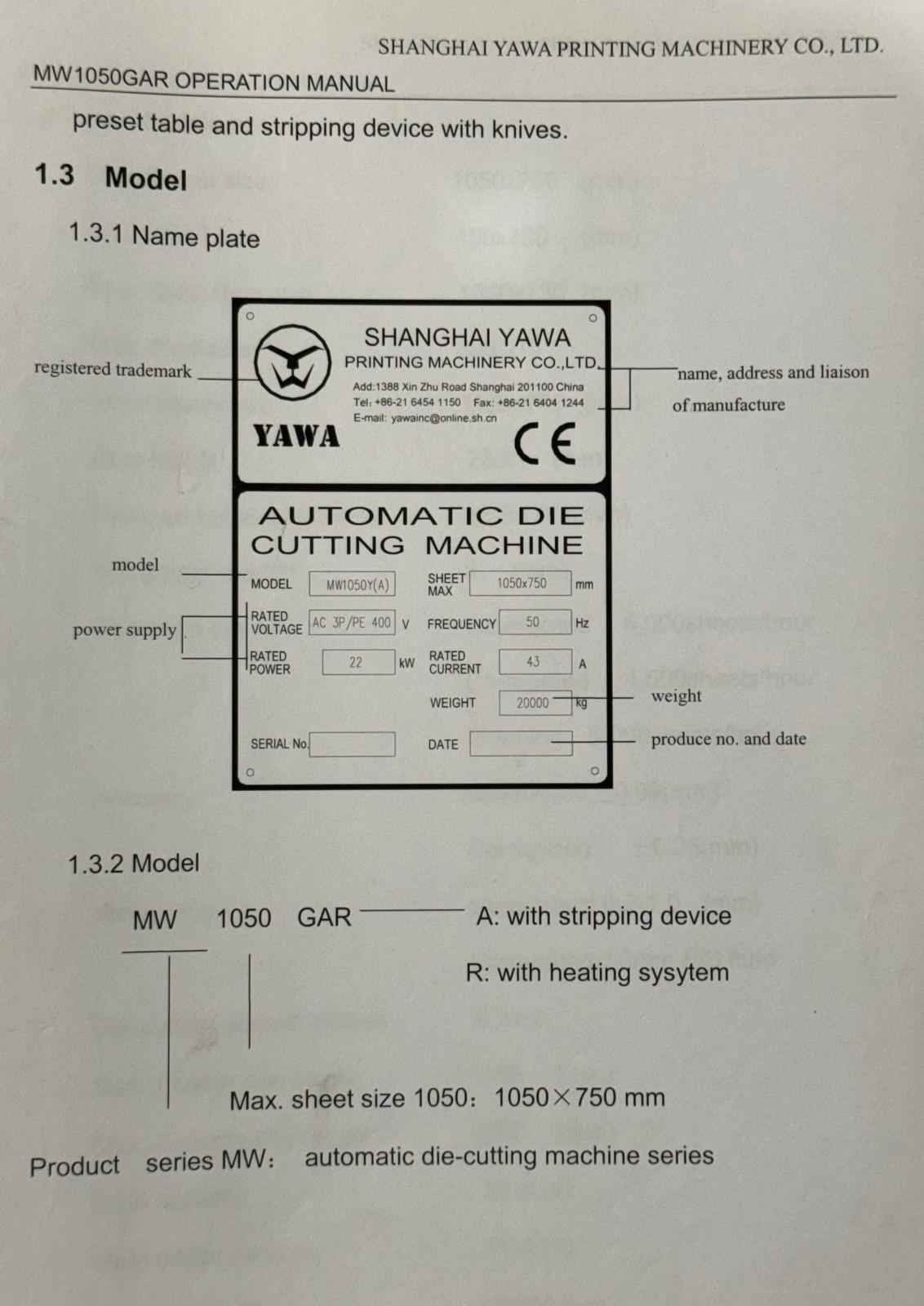

Machine overview

| Year | 2013 |

|---|---|

| Serial Number | GAR 143020 |

| N.of Impressions | 24 mio. |

“EXTRA” Accessories Overview

- Additional blowers for papaer

- Photocells for sheet travel control for synthetic material

- Upper pull-out frame quick lock

- Nr 2 Upper pull-out quick lock frames

- Nr 4 lower stripping frame for needles

- NON-STOP conveyor in the delivery

- 60 / 5.000 Die cutting machine with heated plate for synthetic materials

Reference Overview

| Reference | 24036444 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset