Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

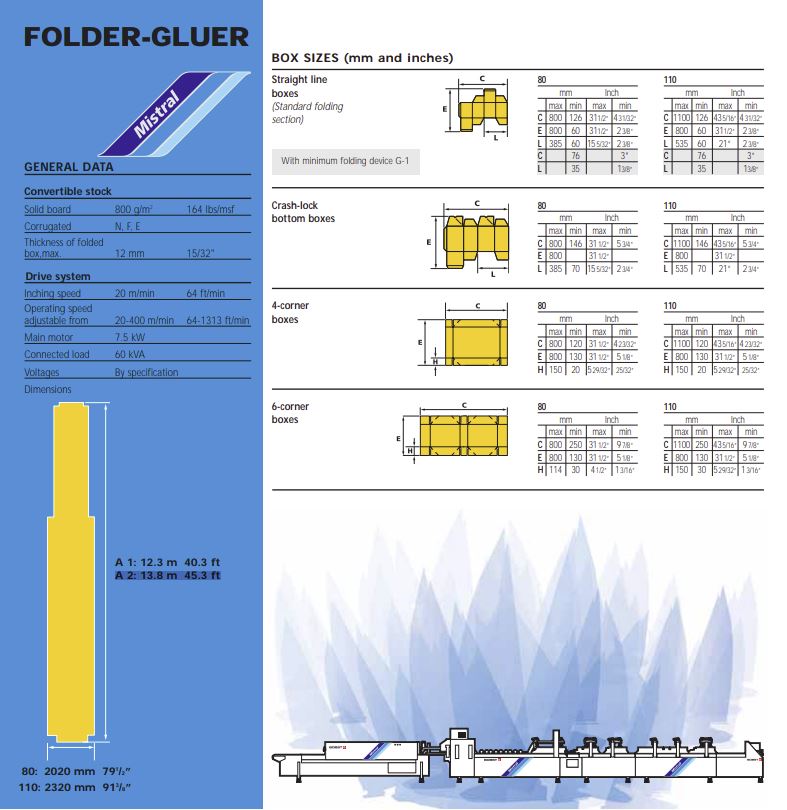

Bobst MISTRAL 110 A2 CS

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | MISTRAL 110 A2 CS |

| Type | Folding Carton Gluing/Piegaincolla |

TECHNICAL DATA

Accessories

- Feeder

- FEEDER : total lenght 1320 mm

- 8 Infeed conveyors with 30 mm belts, with 4 built-in mechanical vibrators

- 1 Thickness gauge. With lateral and longitudinal adjustment and upper introduction rollers

- 1 Additional thickness gauge. With lateral and longitudinal adjustment and upper introduction rollers

- 2 Side lays in two parts. With right gauge equipped with a digital position indicator. Asymmetrical and adjustable longitudinally. Maximum height of the stack of die cut: 350 mm

- 1 Gear-motor. Controlled by a frequency converter for feeding the infeed belts and switching on or off

- 1 Series of adjustable rear guides mounted on a longitudinally adjustable carriage with pneumatic closure

- 1 Lower right transporter. With 25 mm belts and 1 obliquely adjustable upper transport for perfect alignment of the die cuts

- 1 Left Pre breaker positioned at 90°

- Pre Breaker

- Total lenght 2.300 mm

- Lower left conveyor with 43 mm belt. With digital position indicator

- 1 Lower right transporter. With 25 mm belts. With digital position indicator

- 1 Set of upper conveyors with 25mm belts and lifting device

- 1 Left pre-break without belt with built-in presser. Adjustable by eccentric. Max. width of the gluing flap: 30 mm

- 1 Reopening Guide

- 1 Right pre-break with 30 mm strap. Includes a system to adjust the pre-break angle

- 1 lower support guide

- Automatic Bottom

- Total width 1500 mm

- Lower conveyors with 25 mm belts. With digital position indicator

- Upper conveyors with longitudinal adjustment with 25 mm belt

- Lower support guides

- Set of hooks, bending propellers and guides

- Gluer System

- No. 1 bottom glue system on the left with disk and double scraper. With digital position indicator

- 1 Removable glue tank

- 1 Pressure guide with pressure roller

- 1 Filling bottle

- Folder system

- Total length 3000 mm

- 2 Lower conveyors with 25 mm belts. With digital position indicator

- 1 Set of longitudinally adjustable upper conveyors with 25 mm belts and lifting device

- 2 Folding equipment with 10/15/30 mm belts

- 2 Pressure rollers adjustable by eccentrics

- 2 speed variators for the folding belts

- 2 Integrated devices for lifting the folding belts on the left and right. For folding boxes with protruding flaps

- 1 Lower support guide

- Transfer system

- Total lenght 1400 mm

- 2 Lower conveyors with longitudinal adjustment with 25 mm belt. With digital position indicator

- 2 Upper conveyors with longitudinal manual adjustment with 25 mm belt

- 1 System for vertical adjustment of the lower and upper conveyor output. With automatic belt tensioning system

- 1 Flexible contact safety sensor

- Delivery

- Total length 4425 mm.

- Pressure length 2700 mm.

- 1 Independent exit with belt, width 900 mm.

- 1 Pneumatic pressure system adjustable by spindles. 2 independent adjustment zones

- 1 Automatic lateral correction guide system for the lower and upper belts

- 1 Scale regulator. For automatic stop of the exit in the event of interruption of the case arrival

- 1 Command for temporary acceleration of the exit

- 1 Command for independent start-up of the exit when the machine is stopped

- 1 Gearmotor controlled by a frequency converter. Speed regulation according to the space between the dies, to maintain a regular scale pitch

- Various

- B-5 PRE-BREAKING OR BENDING DEVICE

- B-13 ADDITIONAL TOOLS FOR REINFORCED CRASH-LOCK BOTTOM

- EA-6 MAIN GAUGE WITH LATERAL AND LONGITUDINAL ADJUSTMENT

- EA-8 CALIBER BLADE WITH BLOWER

- EA-15 ELECTRIC PILE VIBRATOR for the rear stack guides. It favors the introduction of blanks adhering to each other

- EA-80 LEFT ALIGNMENT CONVEYOR

- FA-001 LOWER CENTRAL CONVEYOR. With 25mm belts. It ensures and facilitates the transport of disproportionate or large format boxes

- F-5 UPPER CENTRAL CONVEYOR.With 25 mm belts. It ensures and facilitates the transport of disproportionate or large format boxes

- G-15 CENTRAL CONVEYORS. With digital position indicator. Central lower and upper conveyors with 25 mm belts. They ensure good central support for disproportionate or large format boxes

- HB-6 MOTORIZATION OF CONVEYORS. Motorized longitudinal adjustment of the left and right lower transport arms

- J-1 LEFT AND RIGHT INTRODUCER. 30 mm belt introducer. To precisely control the formation of the scale

- J-10 UPPER PRESSURE BELT. This accessory is essential for self-locking bottom and double-wall boxes. To exert additional pressure on a specific point on the box

- J-15 MIRROR. For visual monitoring of the introduction of boxes at the delivery

- J-025 LEFT AND RIGHT INTRODUCER AND RECTIFIER (necessity of: J-001) . To ensure good squaring of the corrugated cardboard self-bottom box. It is composed of corrector pegs operated by pneumatic mandrels

- K-3 KURANDT CODE READER COMPACT SERIES. Reading and checking the code printed on the gluing flap and checking the colours. It is composed of a control box and a reading head

- K-5 KURANDT LOWER GLUE TRACE DETECTOR COMPACT SERIES. Allows you to check the presence and regularity of the trace of glue in the gluing flap

- K-10 BOBST ROTARY EJECTOR with box advancement device. For the extraction of classic small and medium format boxes that do not comply with specifications

- K-15 GLUE LEVEL CONTROL DEVICE. It ensures a constant glue level in the lower left gluer tray. composed of a probe and an automatic tray filling system

- Close and flat box minimum 60 mm.

Machine overview

| Year | 2005 |

|---|---|

| Serial Number | 035603901 |

“EXTRA” Accessories Overview

- B-5 PRE-BREAKING OR BENDING DEVICE

- B-13 ADDITIONAL TOOLS FOR REINFORCED CRASH-LOCK BOTTOM

- EA-6 MAIN GAUGE WITH LATERAL AND LONGITUDINAL ADJUSTMENT

- EA-8 CALIBER BLADE WITH BLOWER

- EA-15 ELECTRIC PILE VIBRATOR for the rear stack guides. It favors the introduction of blanks adhering to each other

- EA-80 LEFT ALIGNMENT CONVEYOR

- FA-001 LOWER CENTRAL CONVEYOR. With 25mm belts. It ensures and facilitates the transport of disproportionate or large format boxes

- F-5 UPPER CENTRAL CONVEYOR.With 25 mm belts. It ensures and facilitates the transport of disproportionate or large format boxes

- G-15 CENTRAL CONVEYORS. With digital position indicator. Central lower and upper conveyors with 25 mm belts. They ensure good central support for disproportionate or large format boxes

- HB-6 MOTORIZATION OF CONVEYORS. Motorized longitudinal adjustment of the left and right lower transport arms

- J-1 LEFT AND RIGHT INTRODUCER. 30 mm belt introducer. To precisely control the formation of the scale

- J-10 UPPER PRESSURE BELT. This accessory is essential for self-locking bottom and double-wall boxes. To exert additional pressure on a specific point on the box

- J-15 MIRROR. For visual monitoring of the introduction of boxes at the delivery

- J-025 LEFT AND RIGHT INTRODUCER AND RECTIFIER (necessity of: J-001) . To ensure good squaring of the corrugated cardboard self-bottom box. It is composed of corrector pegs operated by pneumatic mandrels

- K-3 KURANDT CODE READER COMPACT SERIES. Reading and checking the code printed on the gluing flap and checking the colours. It is composed of a control box and a reading head

- K-5 KURANDT LOWER GLUE TRACE DETECTOR COMPACT SERIES. Allows you to check the presence and regularity of the trace of glue in the gluing flap

- K-10 BOBST ROTARY EJECTOR with box advancement device. For the extraction of classic small and medium format boxes that do not comply with specifications

- K-15 GLUE LEVEL CONTROL DEVICE. It ensures a constant glue level in the lower left gluer tray. composed of a probe and an automatic tray filling system

Reference Overview

| Reference | 24036430 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset