Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

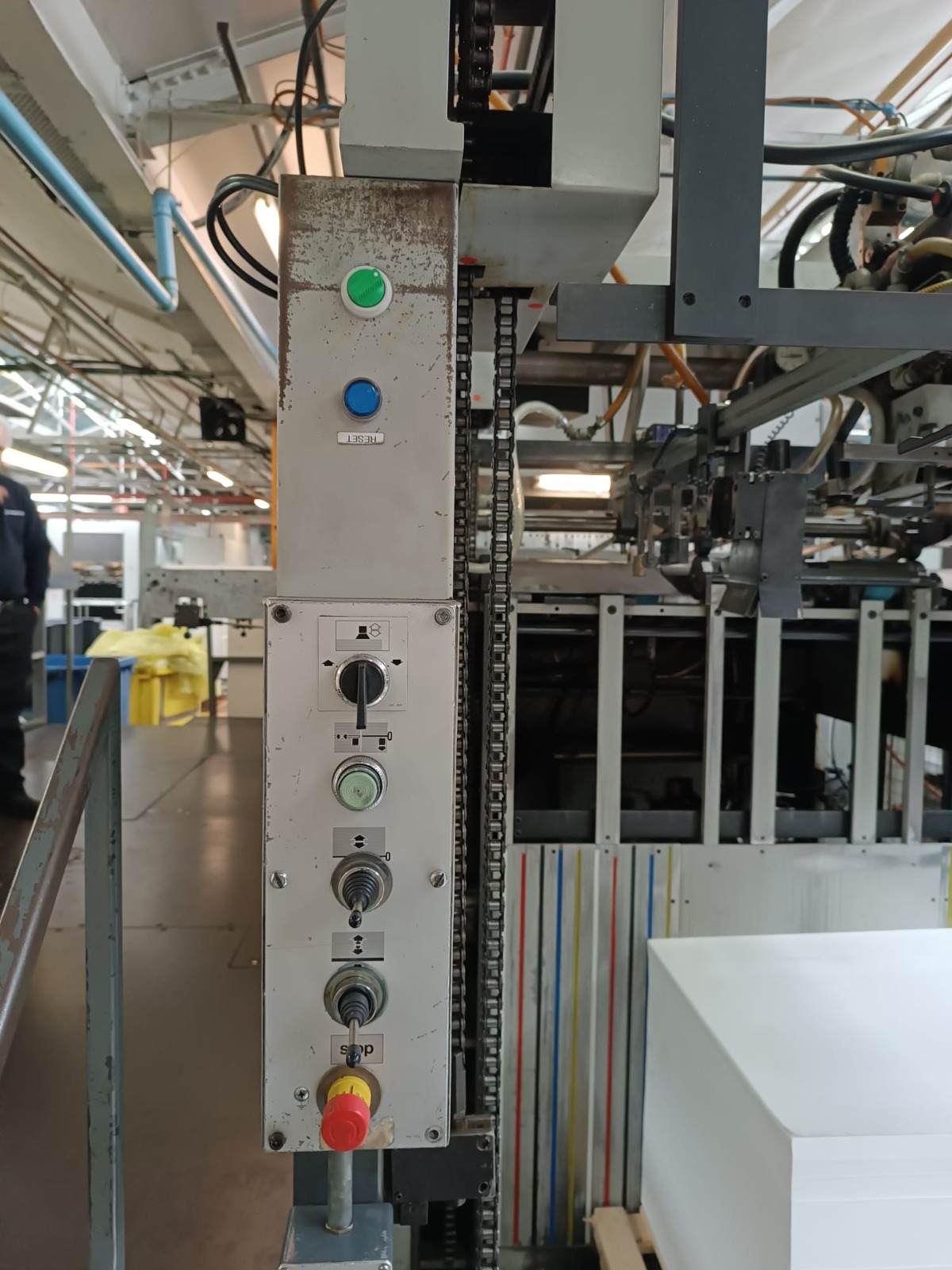

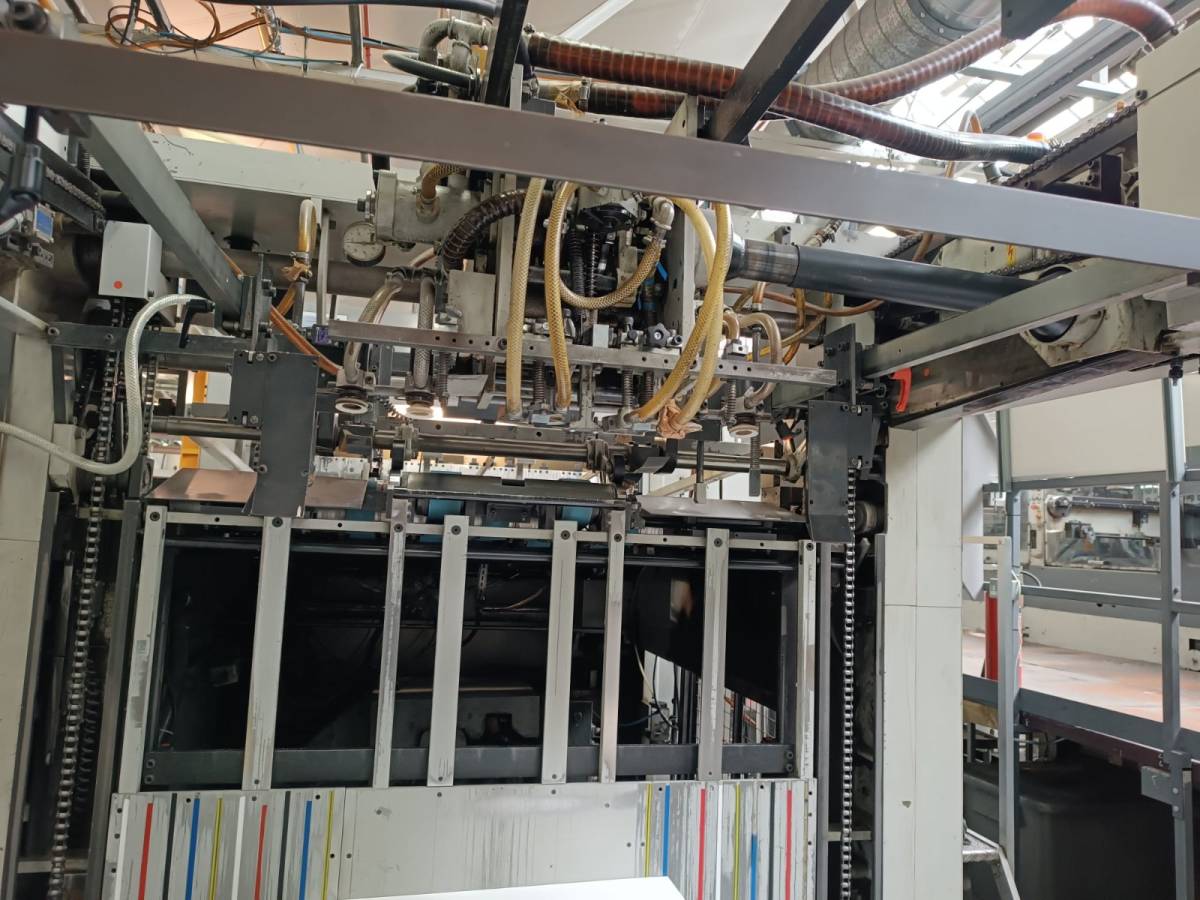

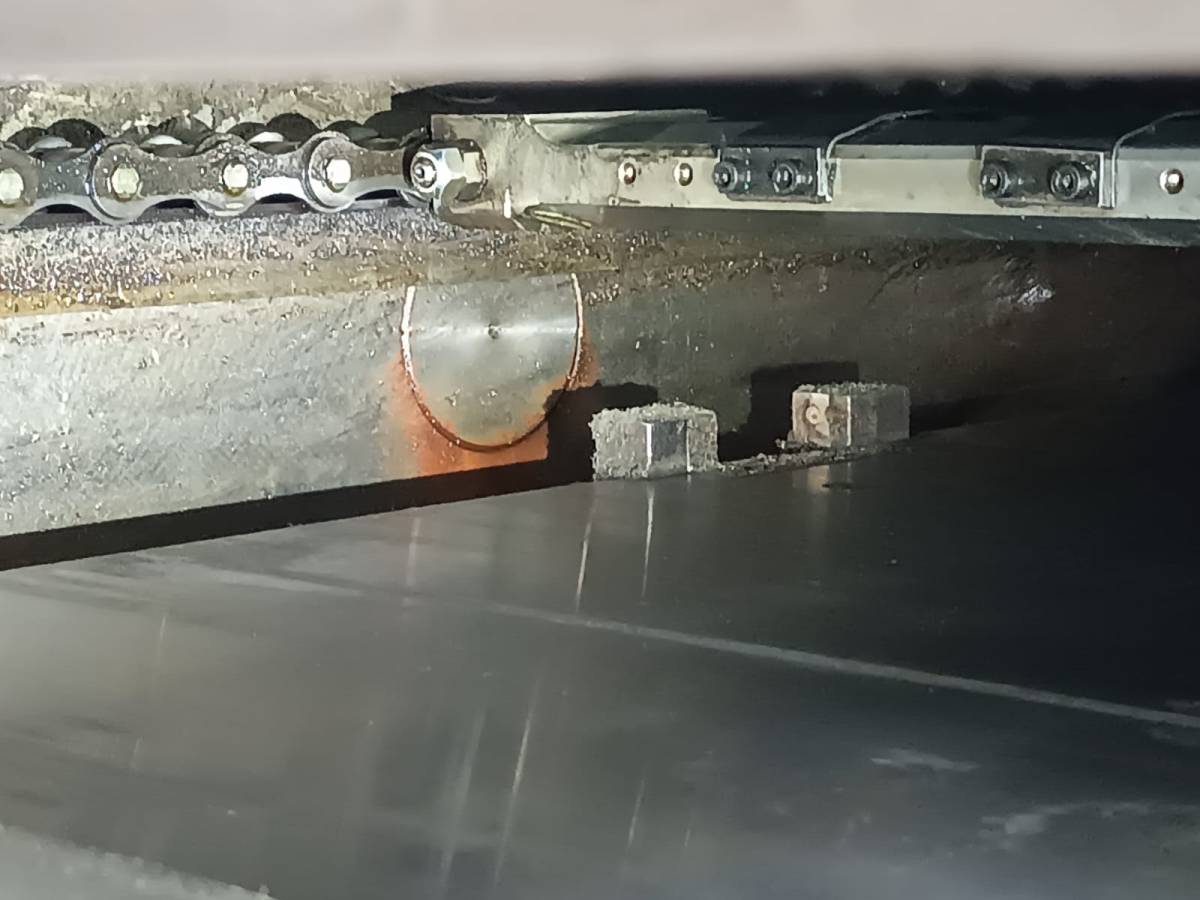

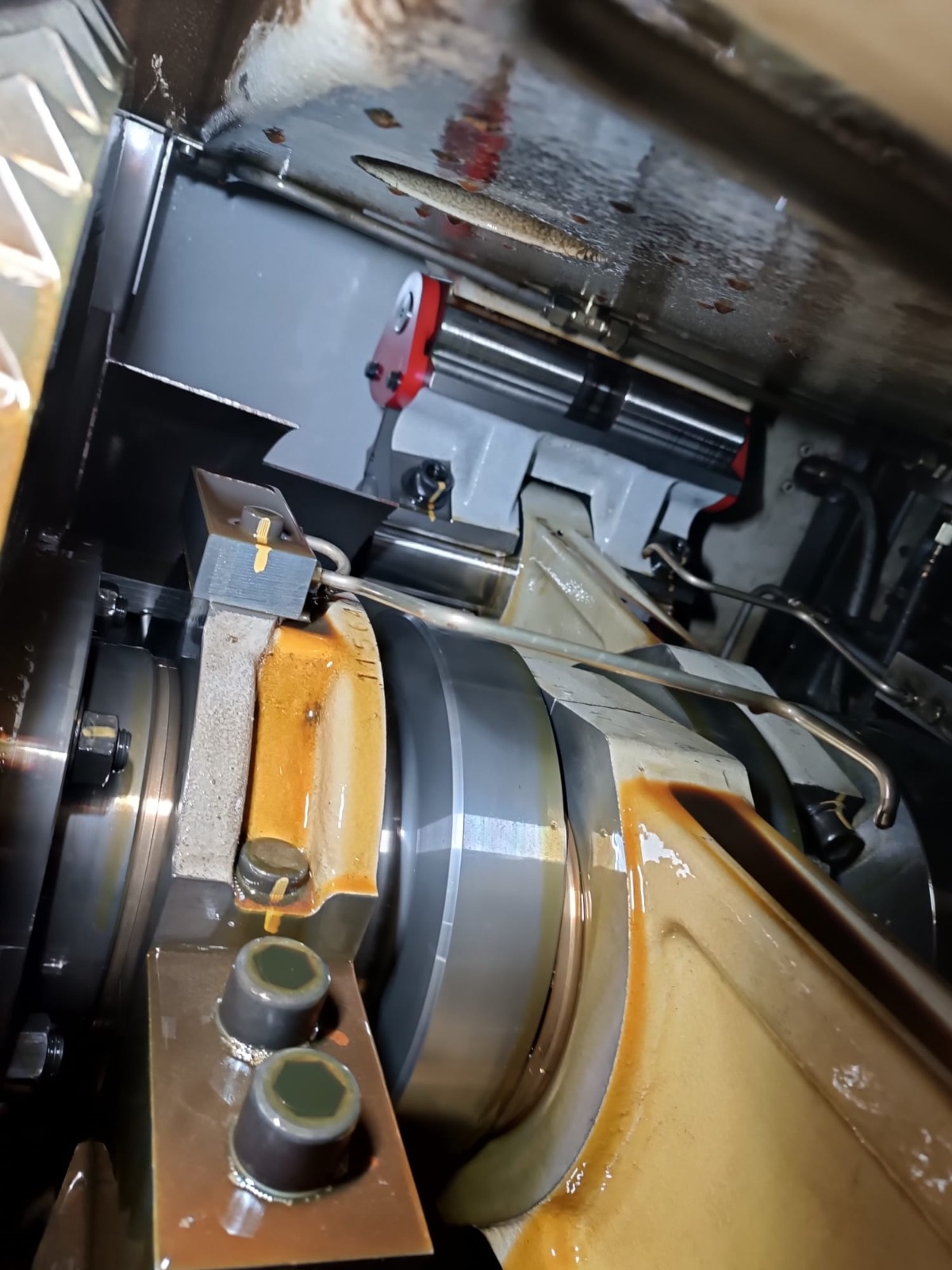

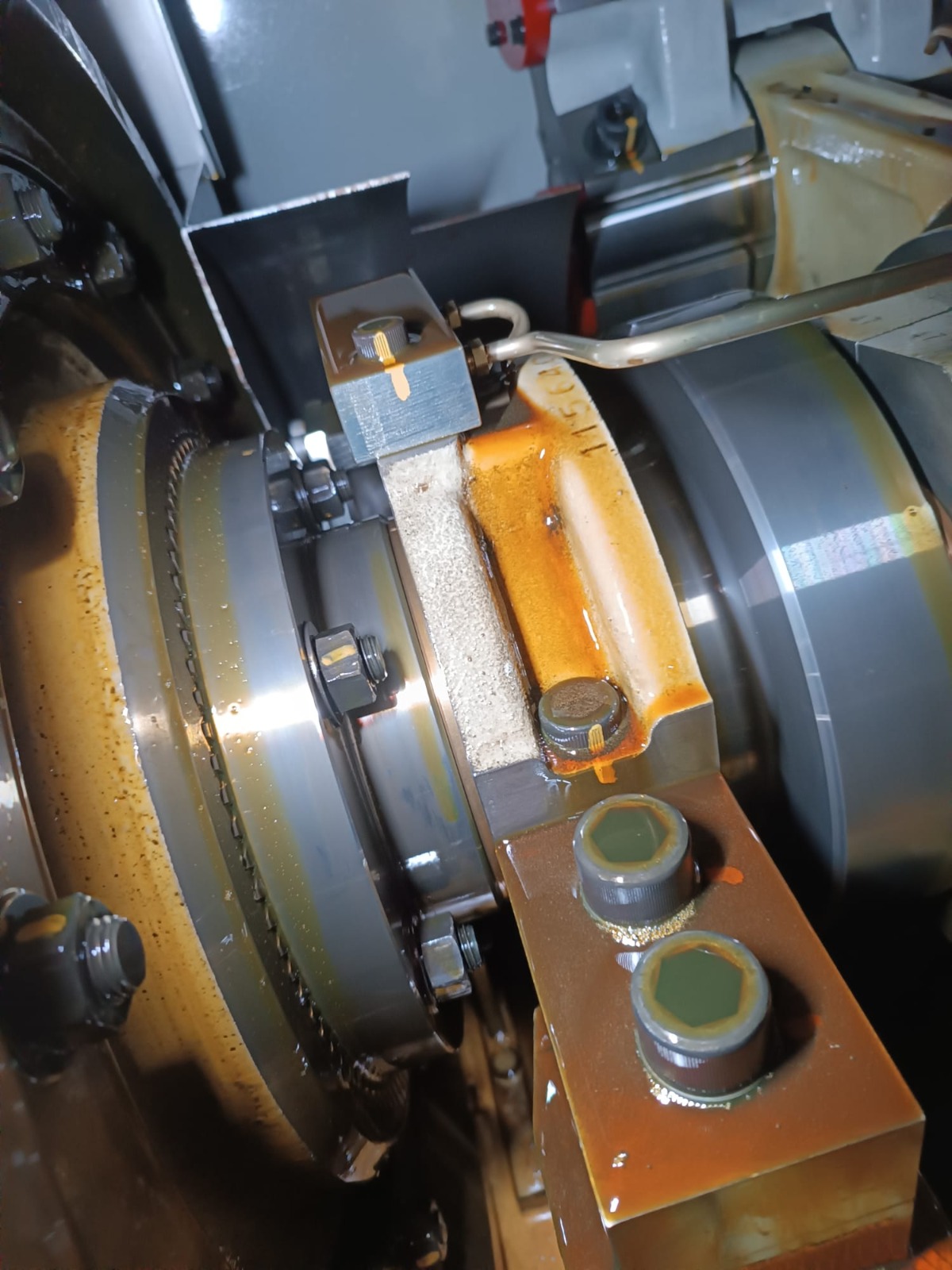

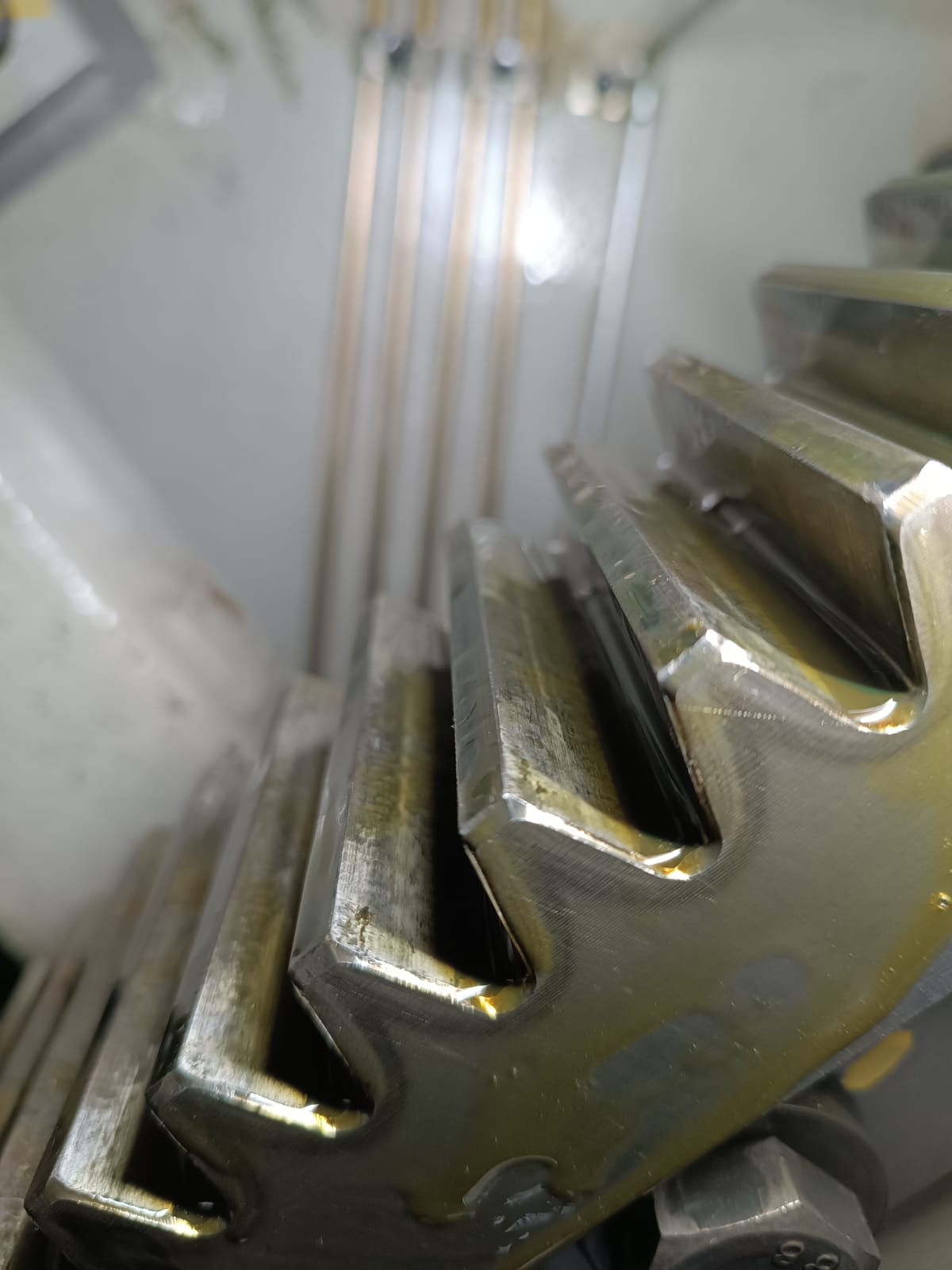

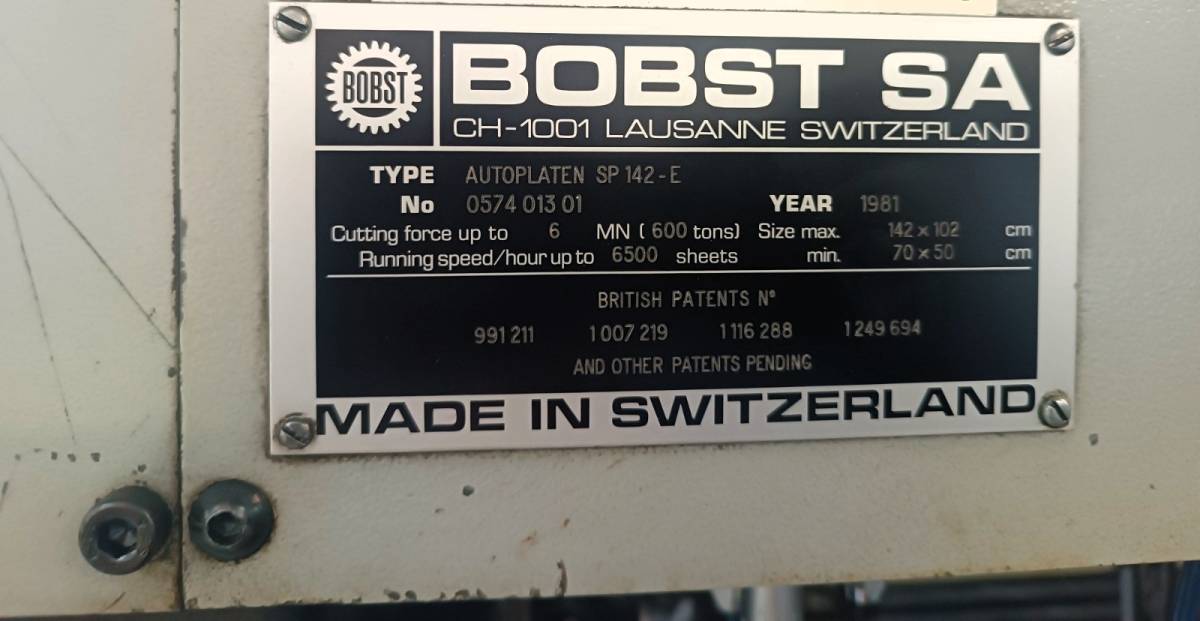

Bobst SP 142 E

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 142 E |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1020 x 1420 |

|---|

Accessories

- Machine

- Step with safety barriers

- Centerline system for quick job changeover

- Electronic device for the sheet passage control

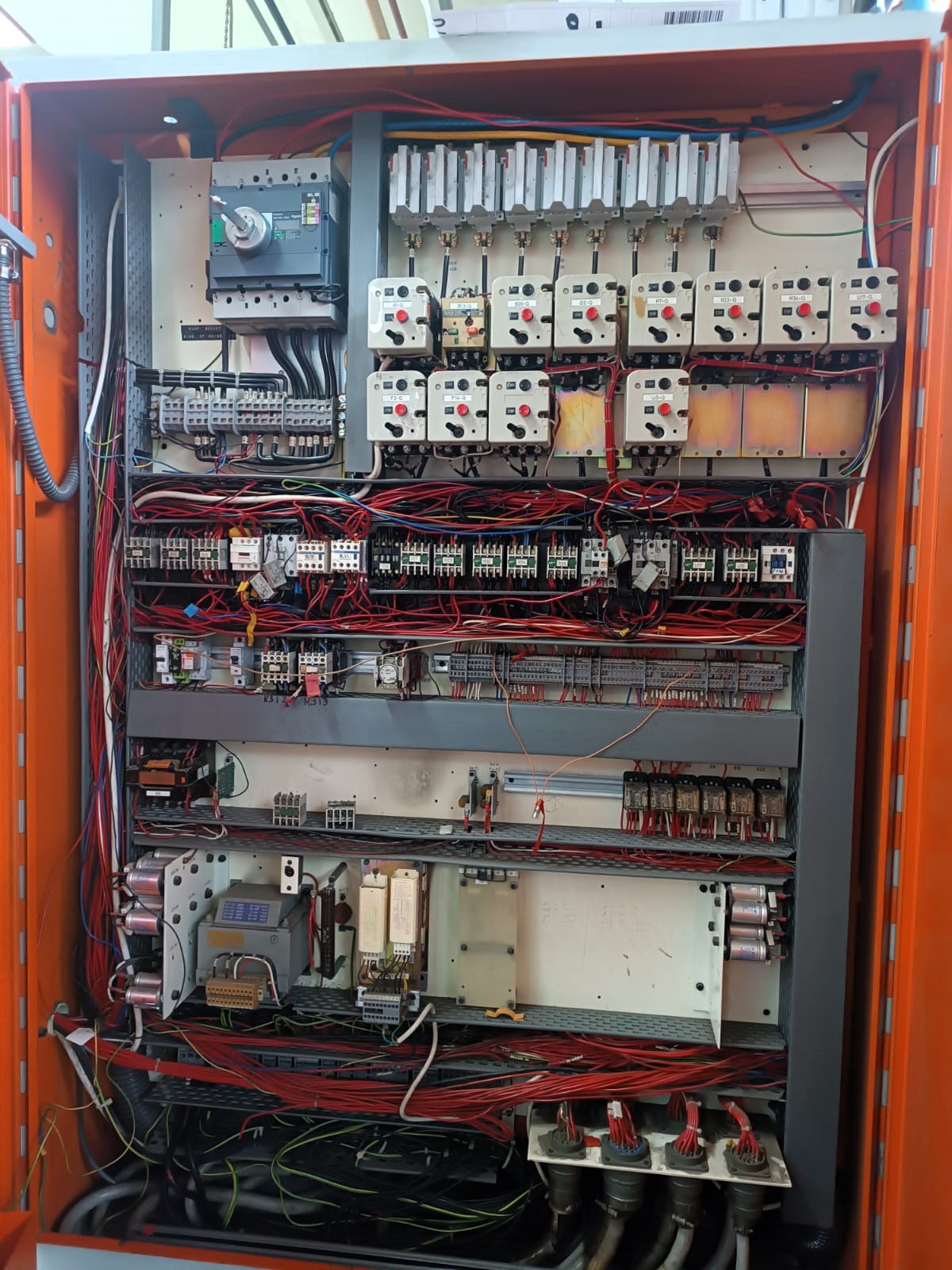

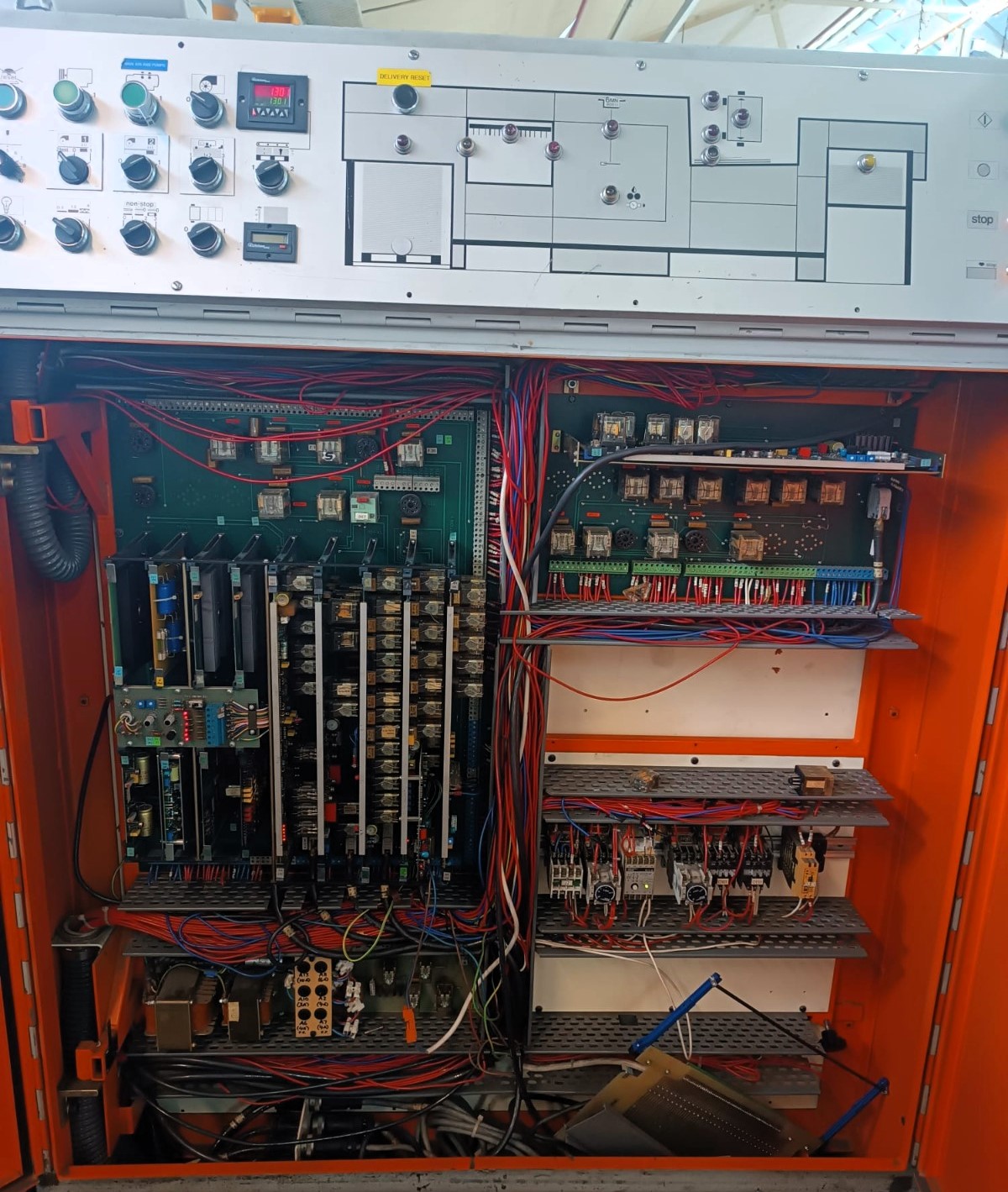

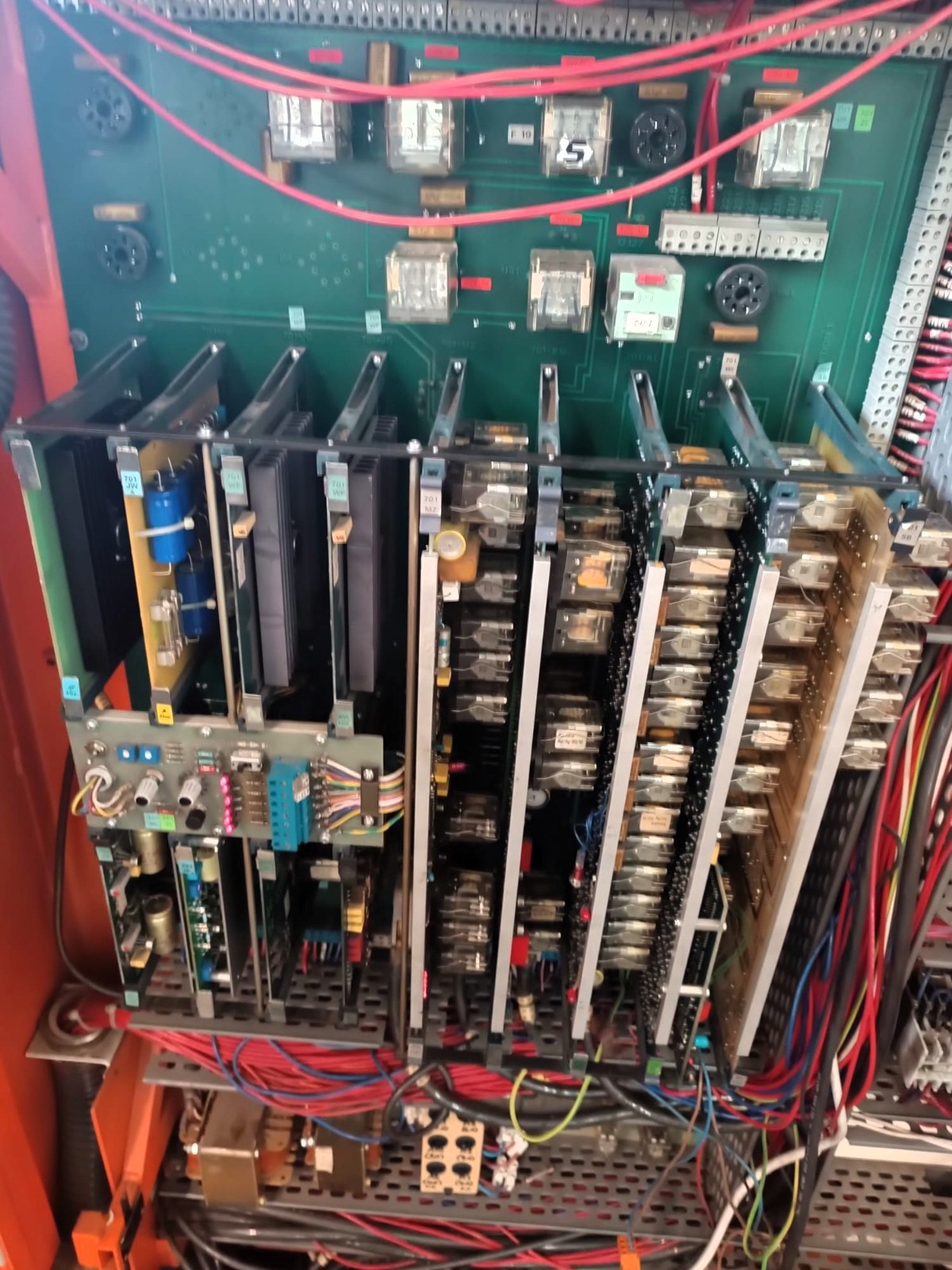

- Bobst-Electronic for the machine control

- ELEVATED 300 mm

- Console

- Centerline

- Feeder

- Pile feeder with automatic lateral moving

- Non-stop on feeder with swords

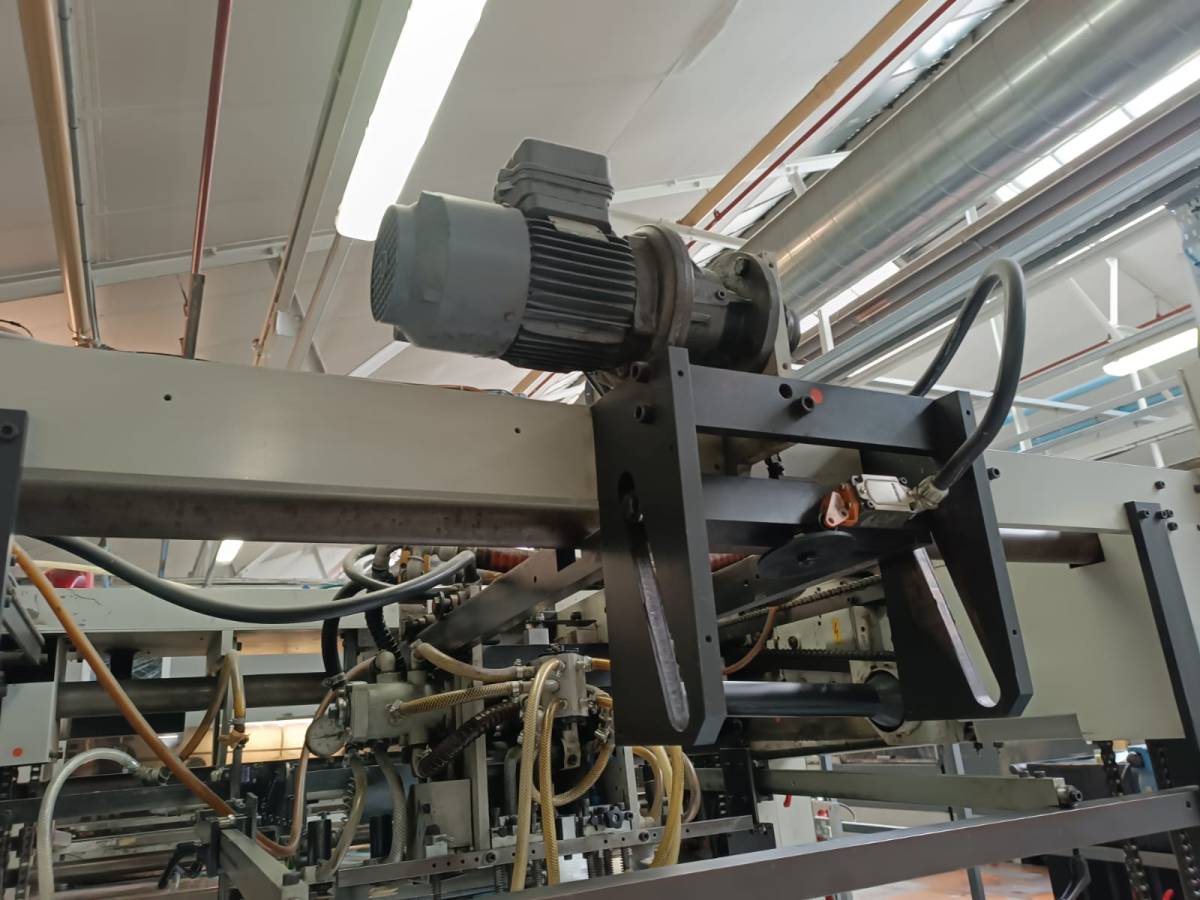

- Motorized suction head unit

- Universal Feeder

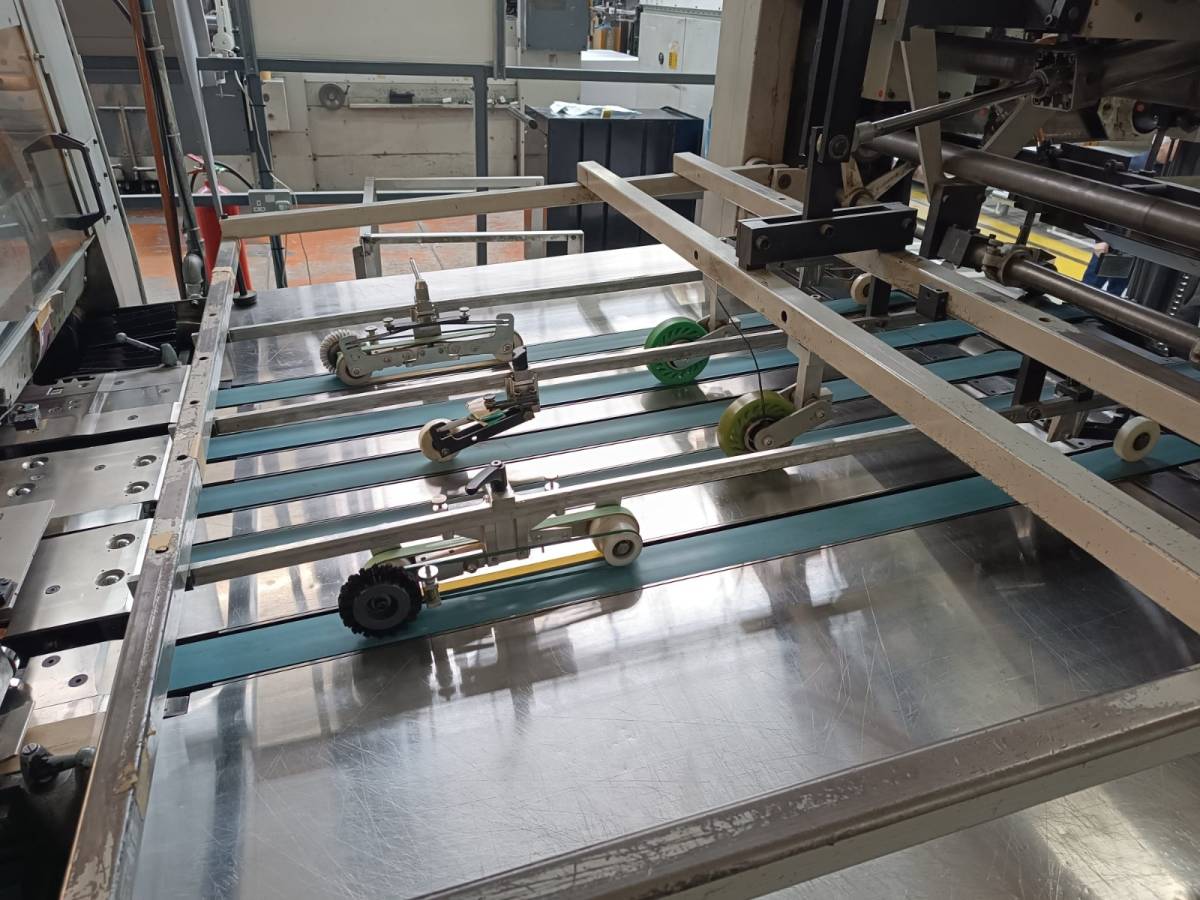

- Introduction table

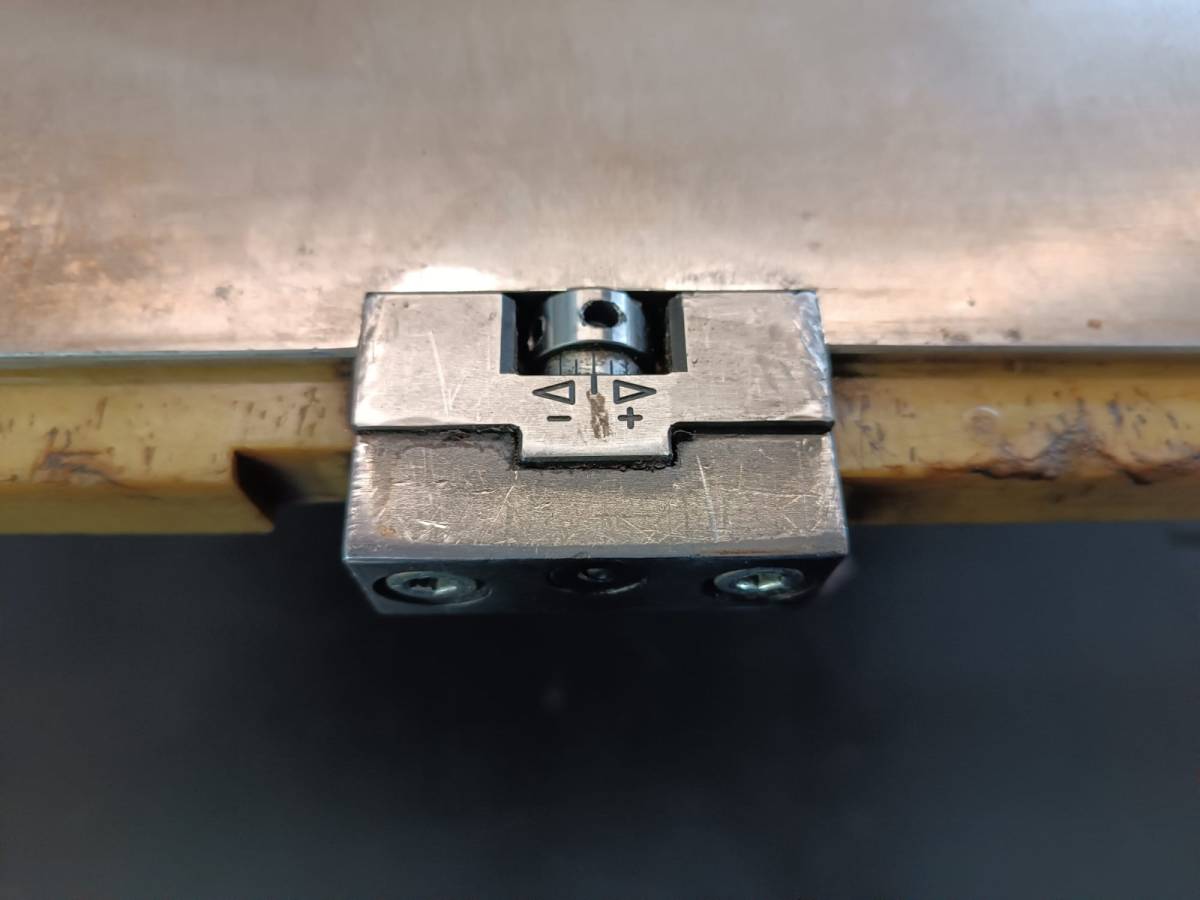

- synchronization to adjust the arrival of sheets to the registers

- Pull-lay operator side (OS) adjustable according to Centerline, with sheet control

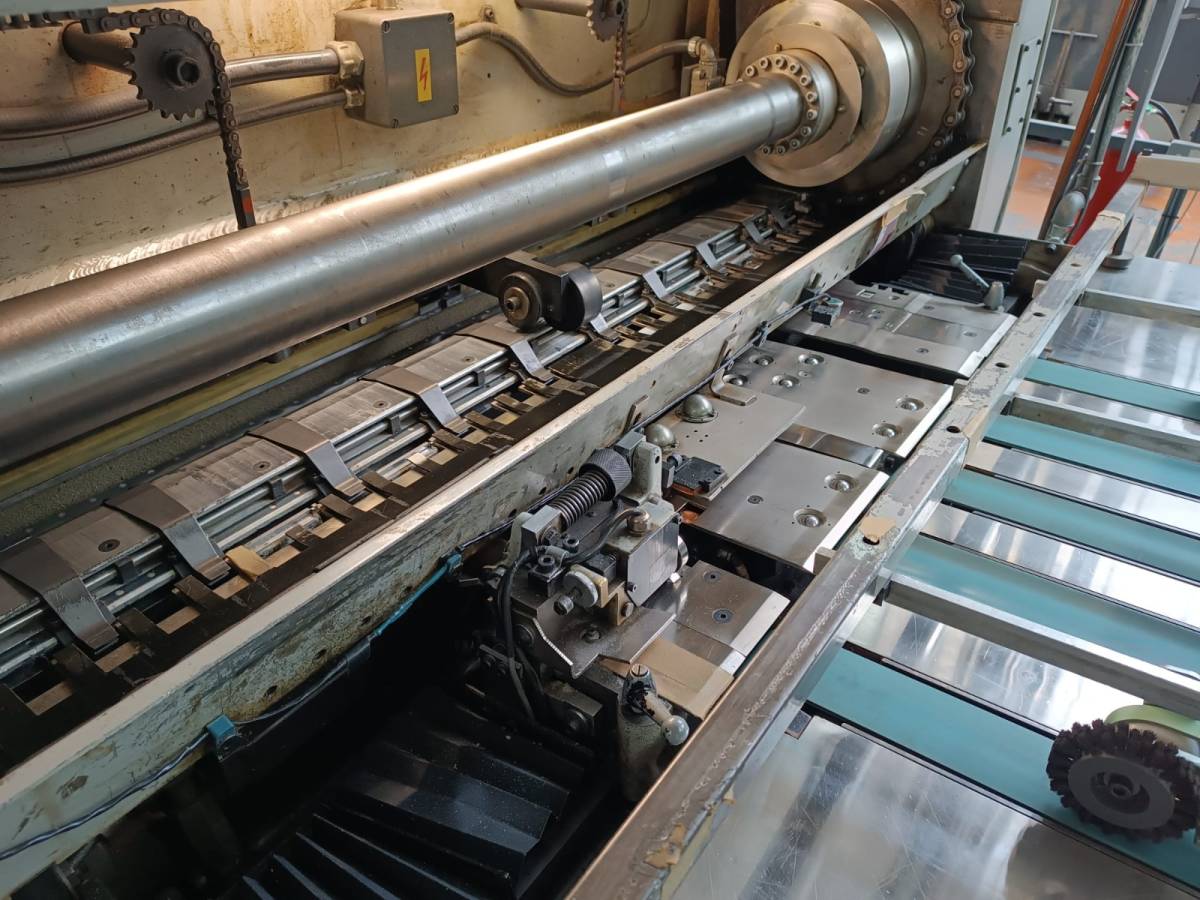

- D-7 REINFORCED SHEET TRANSPORT EQUIPMENT for rigid and corrugate cardboard included: Introducers and upper belts - Upper transport elements (wide belts)

- Guide belt device on feeder table

- Stripping Station

- F-2 : N. 1 Upper pull-out frame

- Delivery

- Guillotine device for front trim

- G-5 AUTOMATIC NON-STOP ON DELIVERY

- Various

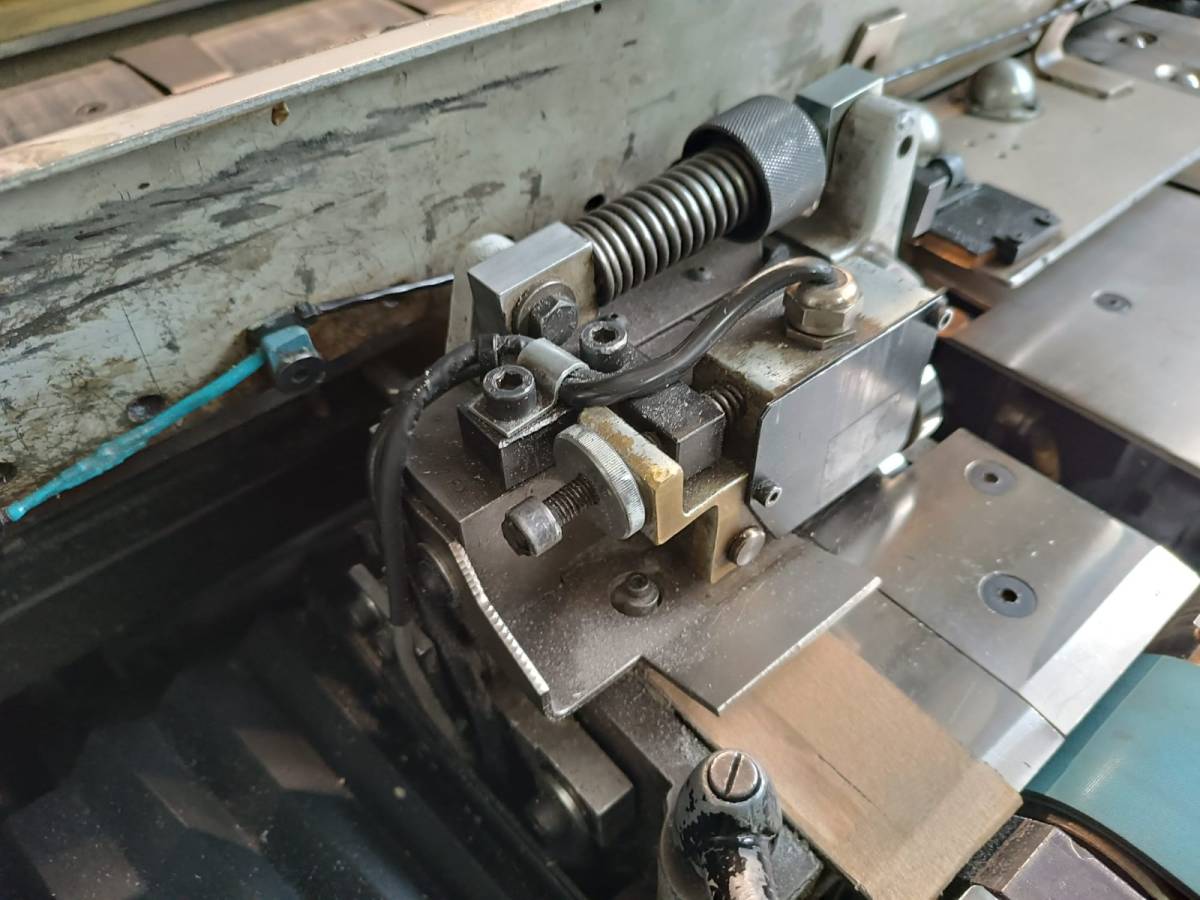

- Micrometric system with compensating plate and 1 mm small metals sheet

Machine overview

| Year | 1981 |

|---|---|

| Serial Number | 053403303 |

| N.of working hours | 27629 |

“EXTRA” Accessories Overview

- ELEVATED 300 mm

- Pile feeder with automatic lateral moving

- Motorized suction head unit

- Universal Feeder

- D-7 REINFORCED SHEET TRANSPORT EQUIPMENT for rigid and corrugate cardboard included: Introducers and upper belts - Upper transport elements (wide belts)

- Guide belt device on feeder table

- Guillotine device for front trim

- G-5 AUTOMATIC NON-STOP ON DELIVERY

- Micrometric system with compensating plate and 1 mm small metals sheet

Reference Overview

| Reference | 24036420 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

Note:

-Machine Fully Equipped

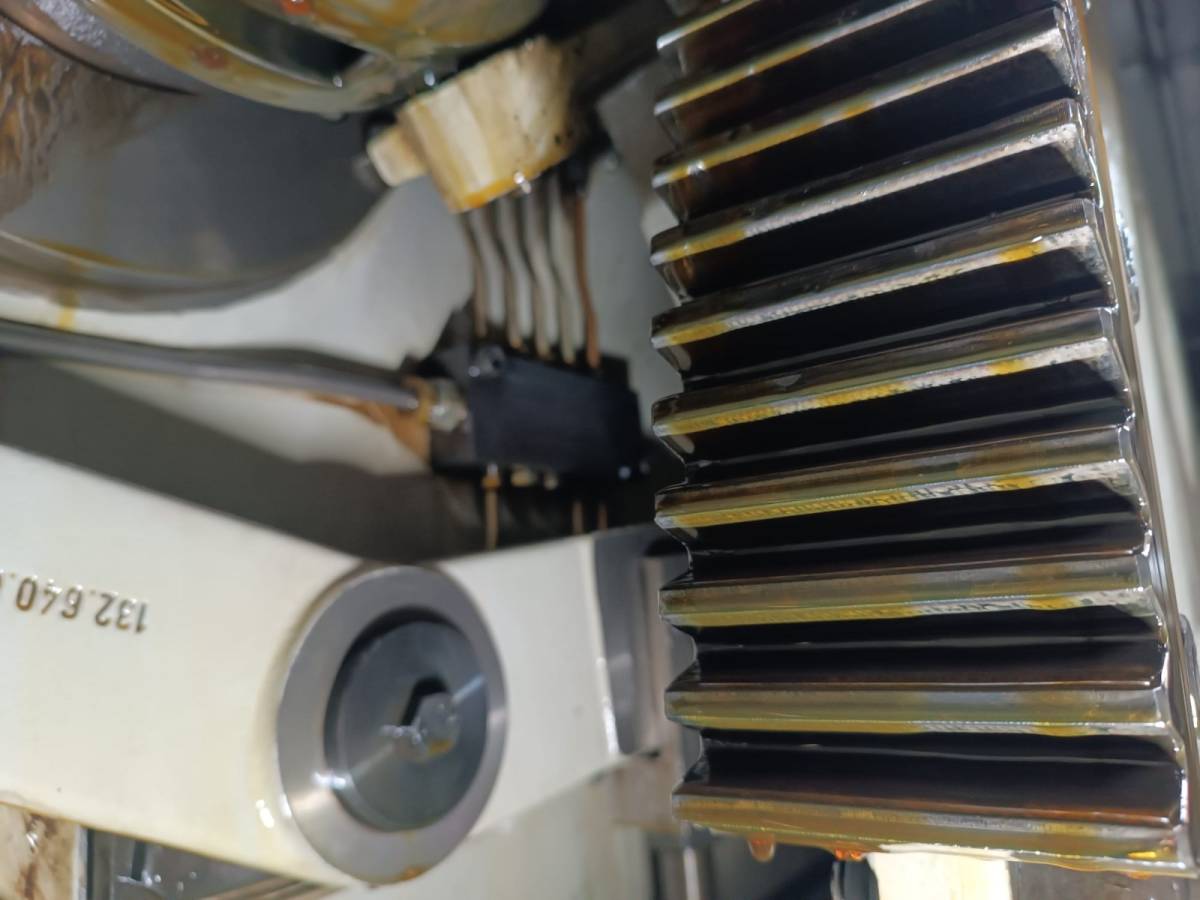

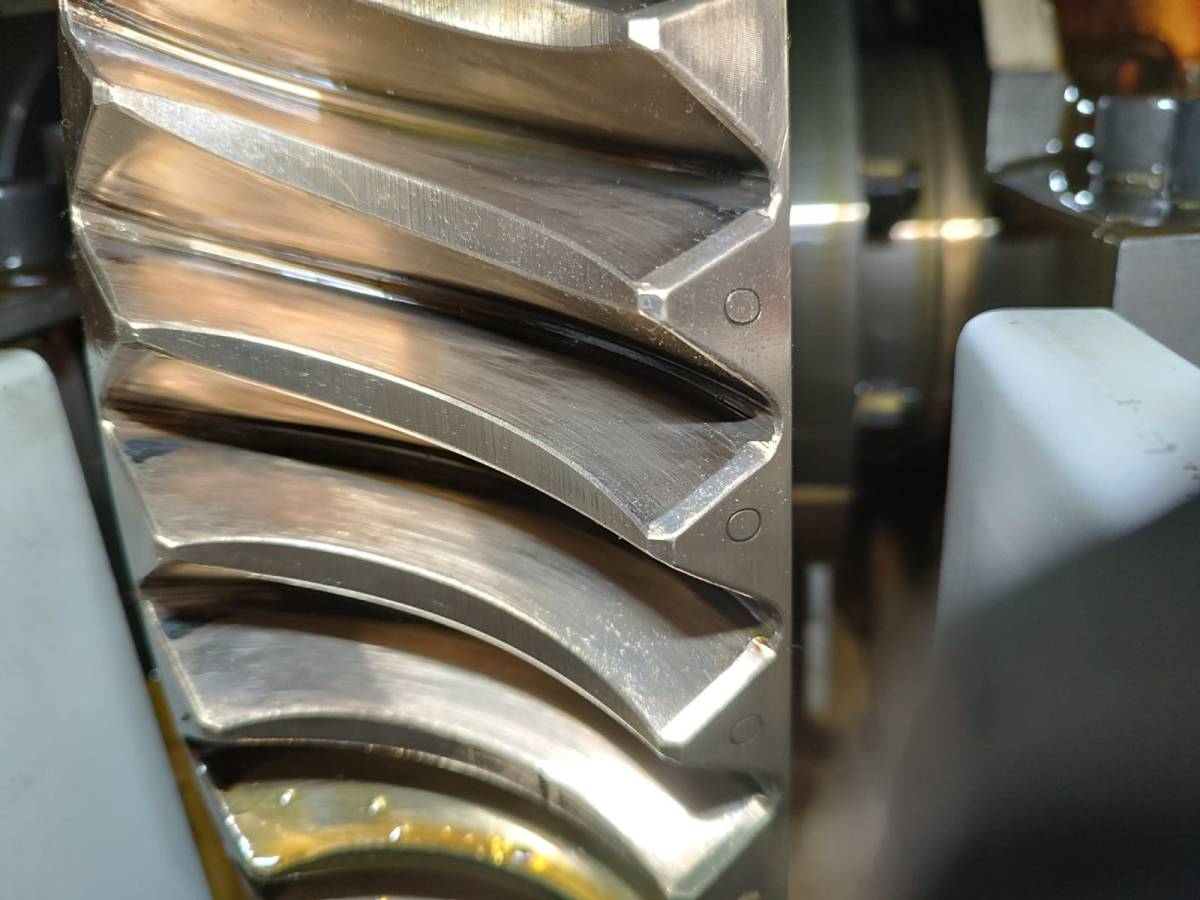

-Completely Retrofitted and Rebuilt by Bobst in 2015 for PDS 164.121: Double cams etc for sector drive, Parts for crankshaft failure, Worm gear wheel for crankshaft, Toggle levers and pins, Plummer black for crankshaft, keys.

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset