Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

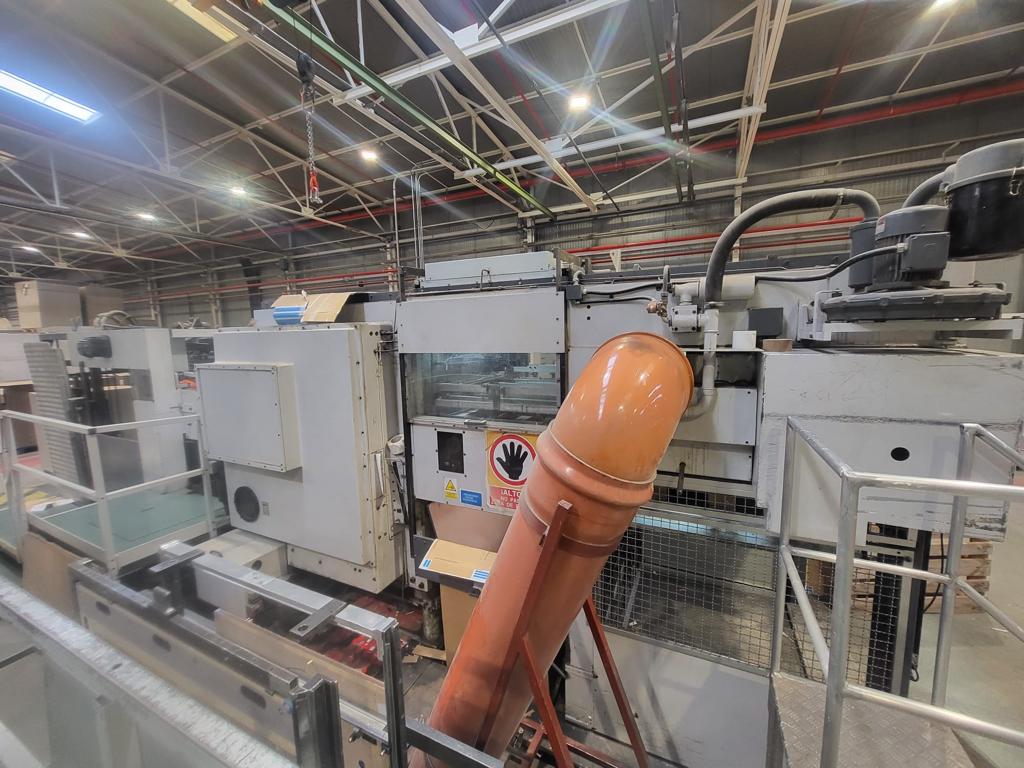

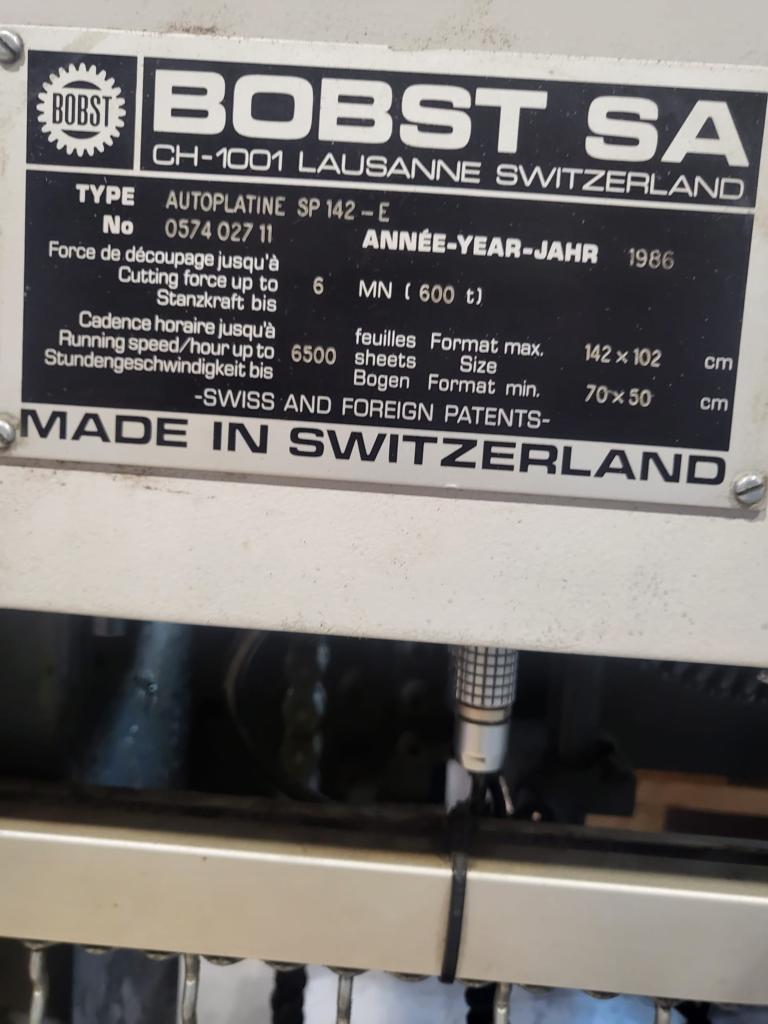

Bobst SP 142 E

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 142 E |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1020 x 1420 |

|---|

Accessories

- Console

- Centerline

- Feeder

- Motorized suction head unit

- Pile feeder with automatic lateral moving

- Universal Feeder

- Non-stop on feeder with swords

- Introduction table

- Sheet-hold down device (Introduction sheets guide in gripper)

- Pull-lay operator side (OS) adjustable according to Centerline, with sheet control

- Receiving pull lay of the push lay operator side

- PULL LAY OPERATOR OPPOSITE SIDE (OOS)

- PUSHING LAY FOR CORRUGATE OPPOSITE OPERATOR SIDE (OOS)

- Electronic double sheet device

- D-7 REINFORCED SHEET TRANSPORT EQUIPMENT for rigid and corrugate cardboard included: Introducers and upper belts - Upper transport elements (wide belts)

- Adjustable sheet synchronizer while running, allows to adapt the feeder cycle to that of the platen

- Feed table with 4 front lays, adjustable in pairs with front register control

- Side-guided carrying straps

- Platin

- E-5 COMPENSATING PLATE. THICKNESS 4 MM. IN GROUND STEEL

- E-55 ADJUSTABLE SUPPORTING PLATE CENTERINGS

- Stripping Station

- 1 "GRID" UPPER PULL-OUT FRAME WITH ALL ITS STANDARD TOOLS

- CENTRAL PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT WITH ALL ITS TOOLS

- F-8 1 LOWER STRIPPING PULL-OUT FRAME WITH ALL ITS TOOLS

- F-22 Fastening equipment for stripping die (including crossbars and clamps)

- F-35 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- F-2 : N. 1 Upper pull-out frame

- F-81 LOWER STRIPPING EQUIPMENT for waste stripping INCLUDING crossbars, pins and supports (installed on central pull-out frame F-8)

- Micrometric system with compensating plate and 1 mm small metals sheet

- Delivery

- Non-stop delivery with belt convey

- Safety sensors in delivery

- Guillotine device for front trim

- Various

- Elevated 350 mm

Machine overview

| Year | 1986 |

|---|---|

| Serial Number | 057402711 |

| N.of working hours | 76215 |

“EXTRA” Accessories Overview

- Non-stop on feeder with swords

- Receiving pull lay of the push lay operator side

- PULL LAY OPERATOR OPPOSITE SIDE (OOS)

- PUSHING LAY FOR CORRUGATE OPPOSITE OPERATOR SIDE (OOS)

- D-7 REINFORCED SHEET TRANSPORT EQUIPMENT for rigid and corrugate cardboard included: Introducers and upper belts - Upper transport elements (wide belts)

- E-5 COMPENSATING PLATE. THICKNESS 4 MM. IN GROUND STEEL

- E-55 ADJUSTABLE SUPPORTING PLATE CENTERINGS

- 1 "GRID" UPPER PULL-OUT FRAME WITH ALL ITS STANDARD TOOLS

- CENTRAL PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT WITH ALL ITS TOOLS

- F-35 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- Micrometric system with compensating plate and 1 mm small metals sheet

- Safety sensors in delivery

- Guillotine device for front trim

- Elevated 350 mm

Reference Overview

| Reference | 23036346 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset