Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

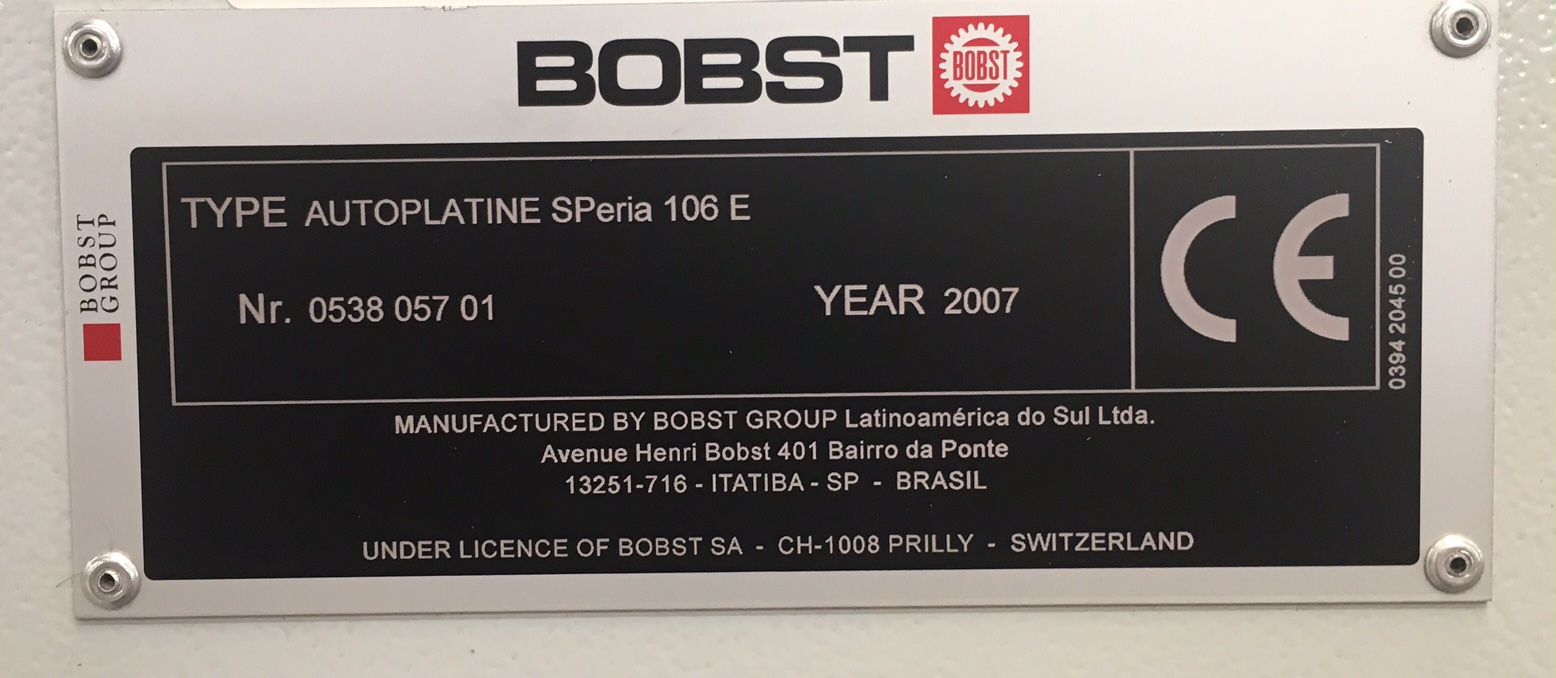

Bobst SPERIA 106 E

The machine was selected and carefully inspected by our engineers prior to purchase. Subsequently, it underwent a rigorous overhaul process, based on a well-established working protocol. This process involves disassembly in our specialized workshop, thorough cleaning, repainting of components and units, accurate reassembly, and the overhaul or replacement of all non-conforming or damaged parts and mechanisms according to our long and established experience. Each component is adjusted with centesimal precision to ensure compliance with original factory parameters. Finally, the machine is reassembled and subjected to thorough functionality tests and inspections for the best result according to our high quality standards.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SPERIA 106 E |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1060 x 740 |

|---|---|

| Min sheet size | 400 x 350 |

Accessories

- Machine

- B-28 INSTALLATION OF THE MACHINE WITHOUT EXCAVATION

- B-7 PLATFORM

- Macchina compatible with HIGHWAY TDF VIEW System

- Centerline system for quick job changeover

- Electronic device for sheet travel control

- Adjustable centering on delivery

- Control cabinet cooling unit

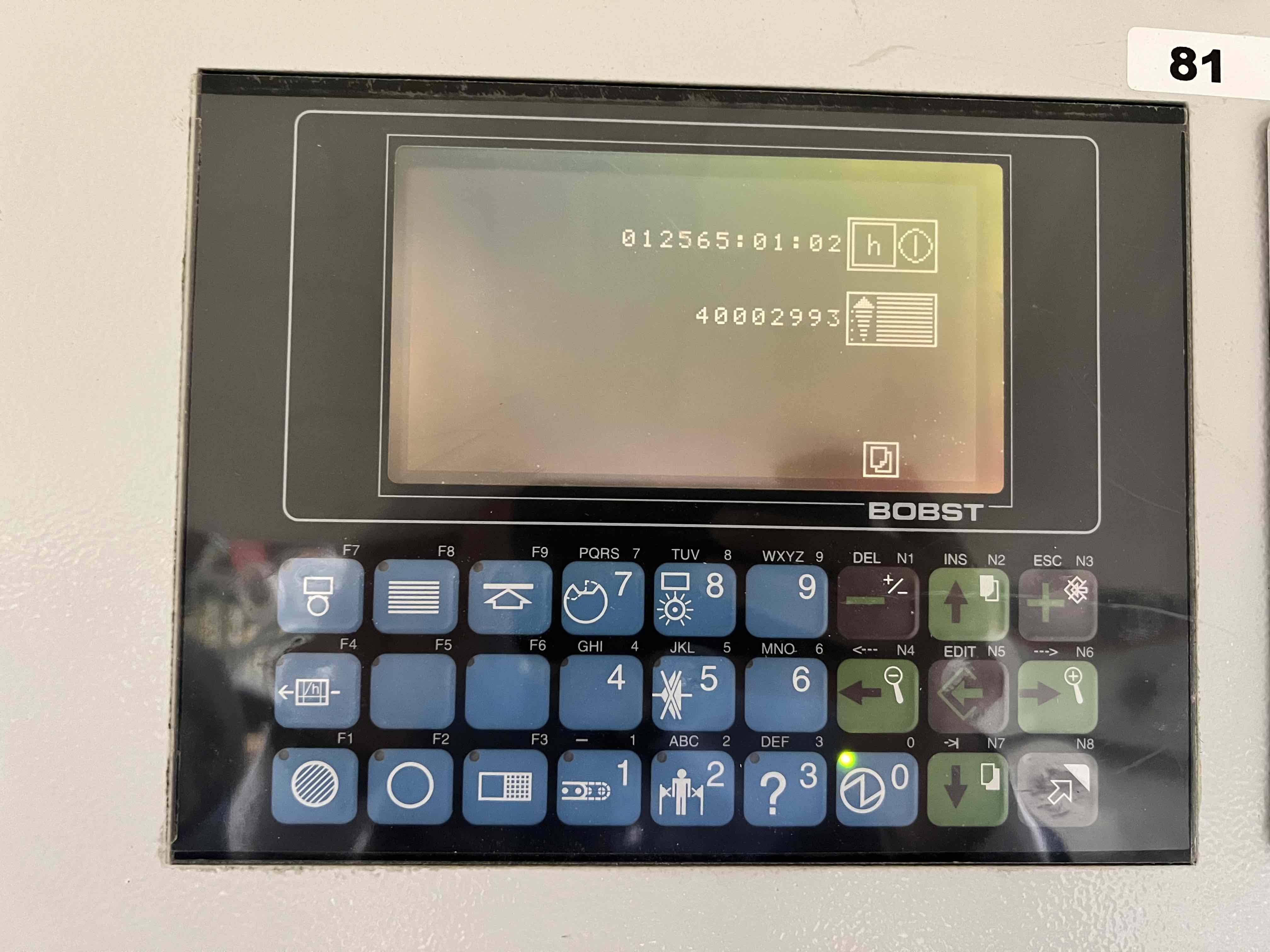

- C.U.B.E. (Control Unit Bobst Electronic) for machine operation

- Main motor with frequency variator

- Feeder

- Pile tray with handle allowing manual lateral correction on the pile during production

- Synchronization device timing the sheet arrival against the front lays when the machine is at a standstill

- Pile lifting controlled by Pressfoot

- Rear pile guide (OS and OOS sides)

- Side blowers adjustable with Centerline marks

- Suction unit

- Safety system for lowering the pile try

- C-4 NON-STOP FEEDER MANUAL DEVICE

- Platin

- Grippers re-opening device (Platin)

- Equipment centering and locking on platin

- Synthetic material supporting plate on platen (Thickness 23.5 mm (0,925")

- E-5 COMPENSATING PLATE. THICKNESS 4 MM. IN GROUND STEEL

- E-55 ADJUSTABLE SUPPORTING PLATE CENTERINGS

- 1 Upper chase-fixed bottom (E-1)

- 1 Cutting plate (E-4)

- Stripping Station

- Quick locking device of the central stripping board

- Motorized lifting of the upper frame

- 1 Upper Stripping Frame (F-2)

- 1 Upper stripping equipment (F-21) required to create a waste stripping tool, including crossbars, clamps, stripper holders and stripping pins of 3, 5 and 10 mm of diameter

- Fastening equipment for stripping die (F-22)

- 1 Adaption material for stripping board on the central frame (quick locking) (F-76)

- 1 lower pull-out frame (F-8)

- 1 Lower stripping equipment (F-81) Equipment for waste stripping including crossbars, pins and supports

- F-31 UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING ((decreases extraction tool assembly times. the quick-closing device allows the tool to be changed in the machine)

- F-35 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- CENTRAL PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT WITH ALL ITS TOOLS

- Various

- The Autoplaten Presses SP 106-E are in conformity with the European Directives for the Safety and Health requirements related to its design and construction, sa well American standards UL 508 and NFPA related to industrial equipment

- Tavolo di introduzione

- Covered with an anti-static stainless steel plate

- Transport belts (with lateral guidance and automatic tensionning system)

- 4 front lays, adjustable in pairs with front register control

- "Pull" guide (OS) adjustable according to Centerline marks, with side register control

- Double sheet detector. Mechanical, integrated on pull guide (OS)

- Sheet-hold down device (guiding the sheets to front lays)

- Upper transport equipment for paper, paperboard and corrugated board

- C-5 SYNCHRONIZATION DEVICE TIMING THE SHEET ARRIVAL AGAINST THE FRONT LAYS WHEN THE MACHINE IS AT A STANDSTILL

- D-1 PULL GUIDE (OOS)

Machine overview

| Year | 2007 |

|---|---|

| Serial Number | 053805701 |

| N.of Impressions | 40 mio. |

| N.of working hours | 12565 |

Conditions Overview

“EXTRA” Accessories Overview

- B-28 INSTALLATION OF THE MACHINE WITHOUT EXCAVATION

- B-7 PLATFORM

- Macchina compatible with HIGHWAY TDF VIEW System

- C-4 NON-STOP FEEDER MANUAL DEVICE

- E-5 COMPENSATING PLATE. THICKNESS 4 MM. IN GROUND STEEL

- E-55 ADJUSTABLE SUPPORTING PLATE CENTERINGS

- F-31 UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING ((decreases extraction tool assembly times. the quick-closing device allows the tool to be changed in the machine)

- F-35 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- CENTRAL PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT WITH ALL ITS TOOLS

- C-5 SYNCHRONIZATION DEVICE TIMING THE SHEET ARRIVAL AGAINST THE FRONT LAYS WHEN THE MACHINE IS AT A STANDSTILL

- D-1 PULL GUIDE (OOS)

Reference Overview

| Reference | 23036326 |

|---|---|

| Visible | Testable in production at Sbm a Robecco sul Naviglio (MI) |

| Availability | Ready for delivery |

Note:

The machine is installed in our WorkShop and die cutting testable. At this time we are using it for training courses for die-cutting operators

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset