Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

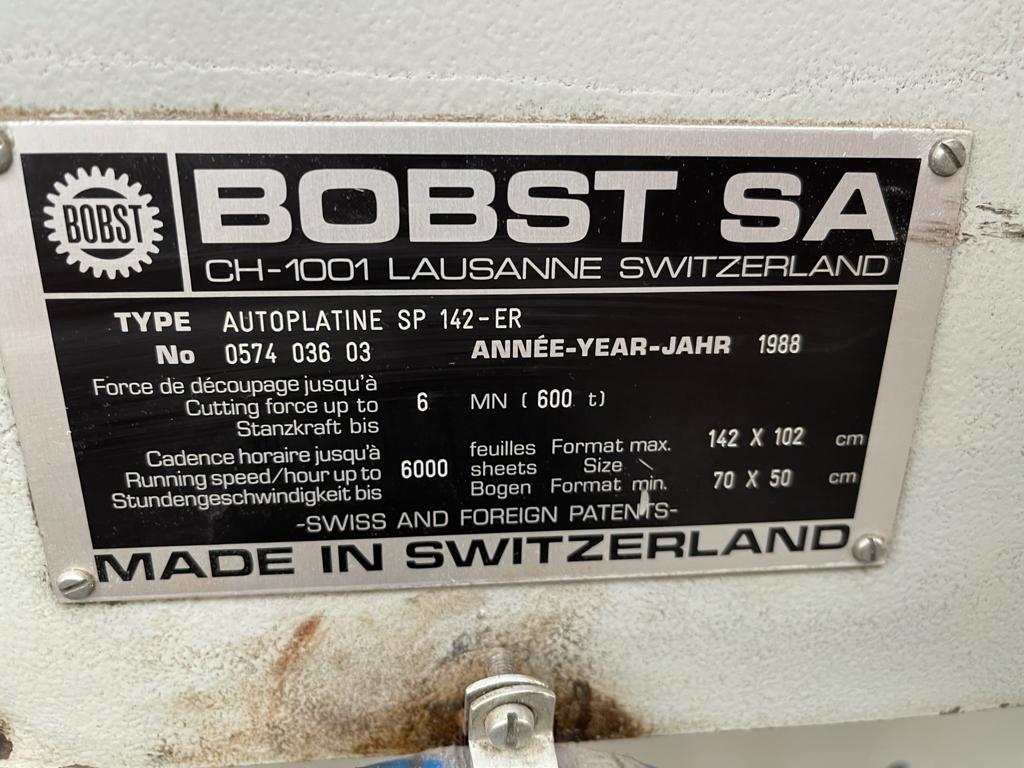

Bobst SP 142 ER

The machine was selected and carefully inspected by our engineers prior to purchase. Subsequently, it underwent a rigorous overhaul process, based on a well-established working protocol. This process involves disassembly in our specialized workshop, thorough cleaning, repainting of components and units, accurate reassembly, and the overhaul or replacement of all non-conforming or damaged parts and mechanisms according to our long and established experience. Each component is adjusted with centesimal precision to ensure compliance with original factory parameters. Finally, the machine is reassembled and subjected to thorough functionality tests and inspections for the best result according to our high quality standards.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 142 ER |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1020 x 1420 |

|---|---|

| Min sheet size | 500 x 700 |

Accessories

- Machine

- Centerline system for quick job changeover

- Bobst-Electronic for the machine control

- ELEVATED 650 mm

- OIL CONDITIONER BOX

- Feeder

- Motorized suction head unit

- Pile feeder with automatic lateral moving

- Non-stop on feeder with swords

- Universal Feeder

- synchronization to adjust the arrival of sheets to the registers

- Introduction table

- Adjustable sheet synchronizer while running, allows to adapt the feeder cycle to that of the platen

- Feed table with 4 front lays, adjustable in pairs with front register control

- Feed table with "Pull" guide (OS) adjustable according to Centerline marks, with side register control

- PULL LAY OPERATOR OPPOSITE SIDE (OOS)

- PUSHING LAY FOR CORRUGATE OPPOSITE OPERATOR SIDE (OOS)

- Electronic double sheet device

- Sheet-hold down device (Introduction sheets guide in gripper)

- D-7 REINFORCED SHEET TRANSPORT EQUIPMENT for rigid and corrugate cardboard included:

- Upper frame with pneumatic lifting device

- Side-guided carrying straps

- Platin

- Support plate with micrometric centering of the cutting sheet for thin plates, thickness 1 mm

- RESOCELL 22.5mm with 4mm compensation plate and 1mm metal sheet

- Stripping Station

- 3 points on lock system on ejection unit

- UPPER PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT WITH ALL ITS TOOLS

- Blanking Station

- 3 points on lock system on blanking unit

- Universal lower tool for blanket

- SHEET BRAKES DEVICE BY "BERNOULLI" SYSTEM ON BLANKING STATION

- UPPER PULL-OUT FRAME QUICK LOCK ON BLANKING UNIT WITH ALL ITS TOOLS

- Delivery

- Wrapper for interlayer sheet infeed

- Conveyor for automatic pallet change in delivery

- Various

- Speed 6.500 c/h

- All machine books, manuals and standard accessories

Machine overview

| Year | 1988 |

|---|---|

| Serial Number | 057403603 |

| N.of working hours | 106000 |

Conditions Overview

“EXTRA” Accessories Overview

- ELEVATED 650 mm

- OIL CONDITIONER BOX

- Non-stop on feeder with swords

- PULL LAY OPERATOR OPPOSITE SIDE (OOS)

- PUSHING LAY FOR CORRUGATE OPPOSITE OPERATOR SIDE (OOS)

- D-7 REINFORCED SHEET TRANSPORT EQUIPMENT for rigid and corrugate cardboard included:

- Support plate with micrometric centering of the cutting sheet for thin plates, thickness 1 mm

- RESOCELL 22.5mm with 4mm compensation plate and 1mm metal sheet

- 3 points on lock system on ejection unit

- UPPER PULL-OUT FRAME QUICK LOCK ON STRIPPING UNIT WITH ALL ITS TOOLS

- 3 points on lock system on blanking unit

- Universal lower tool for blanket

- SHEET BRAKES DEVICE BY "BERNOULLI" SYSTEM ON BLANKING STATION

- UPPER PULL-OUT FRAME QUICK LOCK ON BLANKING UNIT WITH ALL ITS TOOLS

Reference Overview

| Reference | 21036003 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset