Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

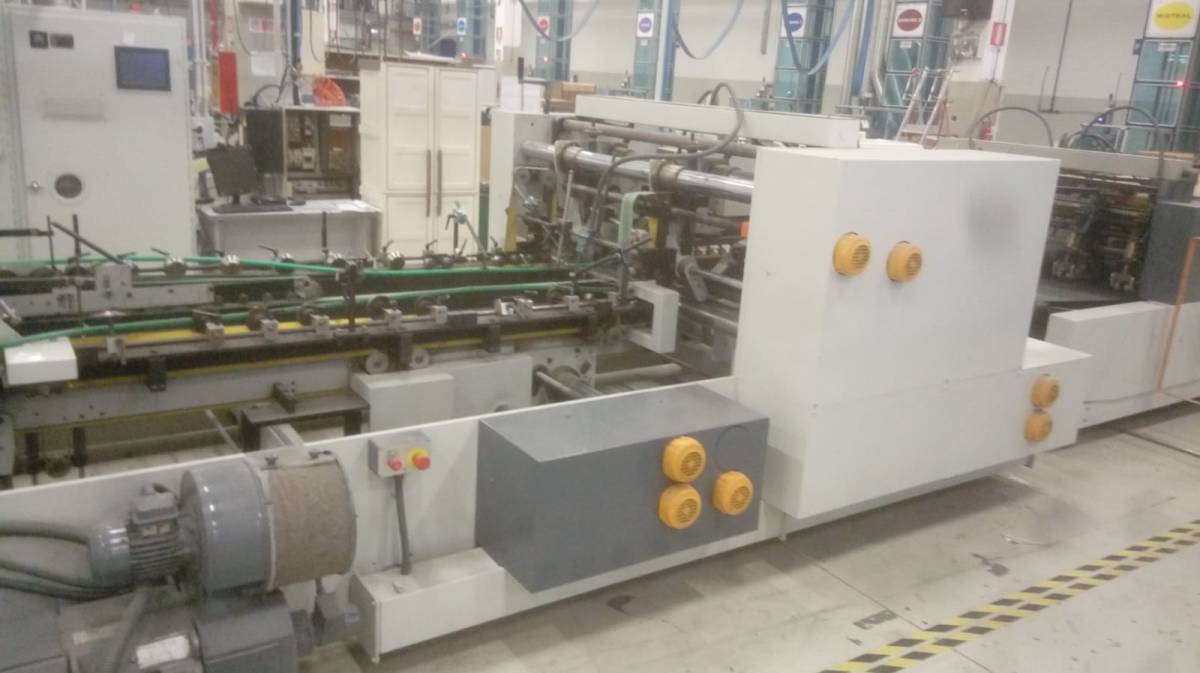

Bobst Domino 145 Matic

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

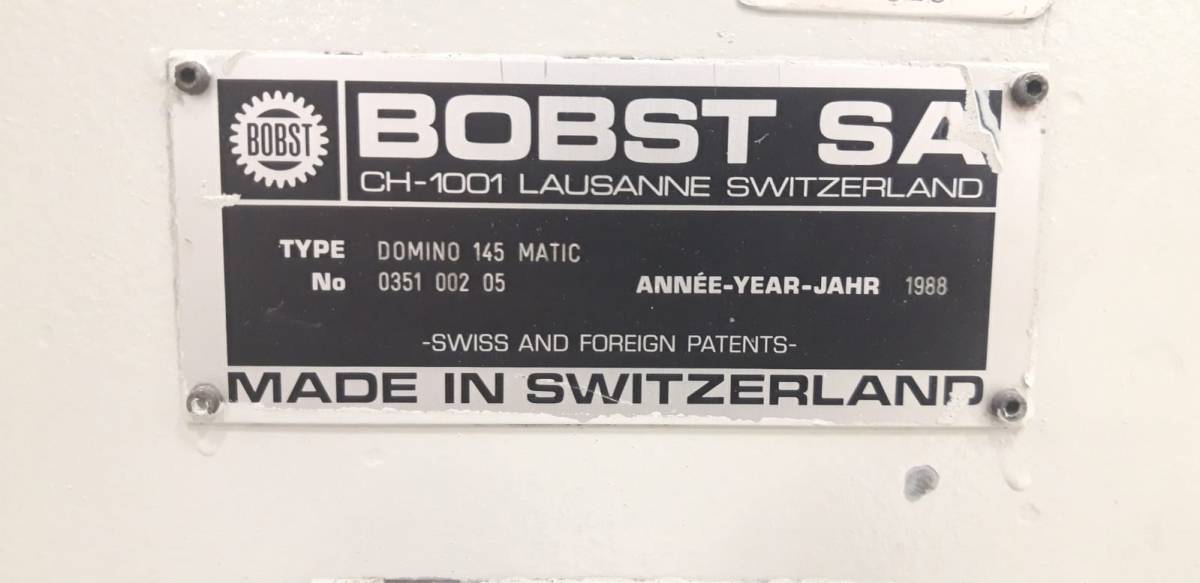

| Manufacturer | Bobst |

|---|---|

| Model | Domino 145 Matic |

| Type | Folding Carton Gluing/Piegaincolla |

TECHNICAL DATA

| Max sheet size | 145 |

|---|

Accessories

- Machine

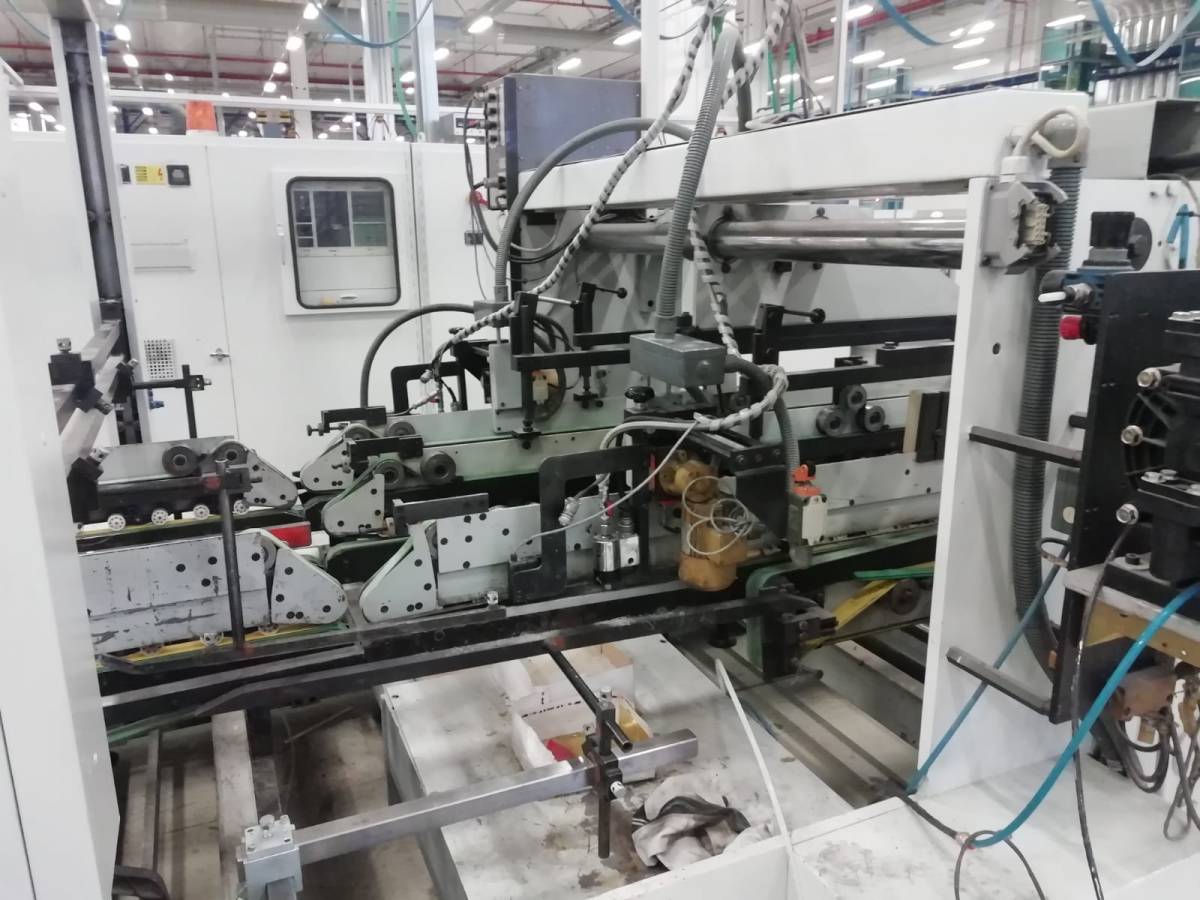

- Straight line boxes

- Automatic Bottom

- Automatic bottom

- Folder system

- 4 corners min. 80 x 120 cm. (depends on kind of flaps)

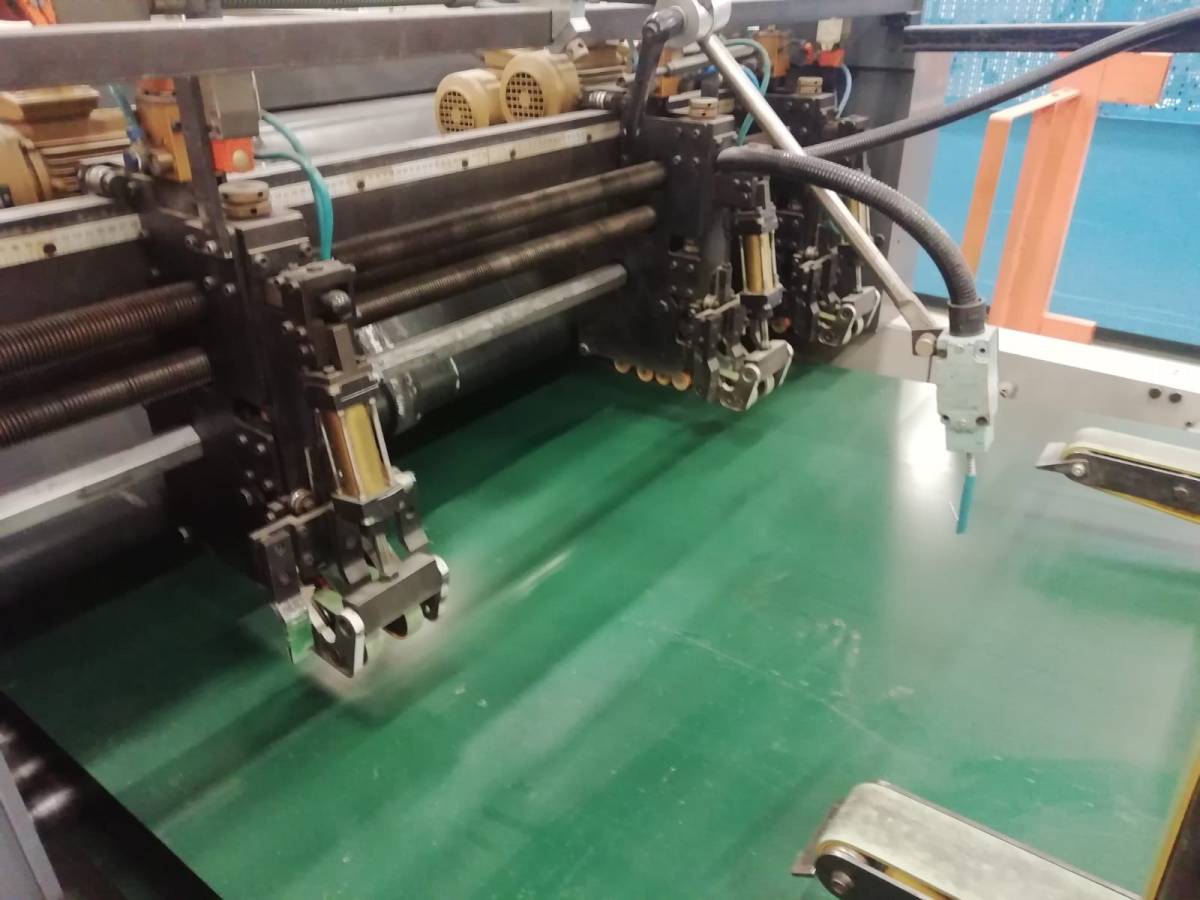

- Transfer system

- All motorized transports

- Delivery

- Pneumatic carpet in delivery

- No. 3 side joggers in delivery

- Various

- No. 2 Mactron motorized guns glue system

Machine overview

| Year | 1988 |

|---|---|

| Serial Number | 035100205 |

“EXTRA” Accessories Overview

- Automatic bottom

- 4 corners min. 80 x 120 cm. (depends on kind of flaps)

- All motorized transports

- Pneumatic carpet in delivery

- No. 3 side joggers in delivery

Reference Overview

| Reference | 21035970 |

|---|---|

| Visible | Testable in production at Sbm a Robecco sul Naviglio (MI) |

| Availability | Immediately |

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset