Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

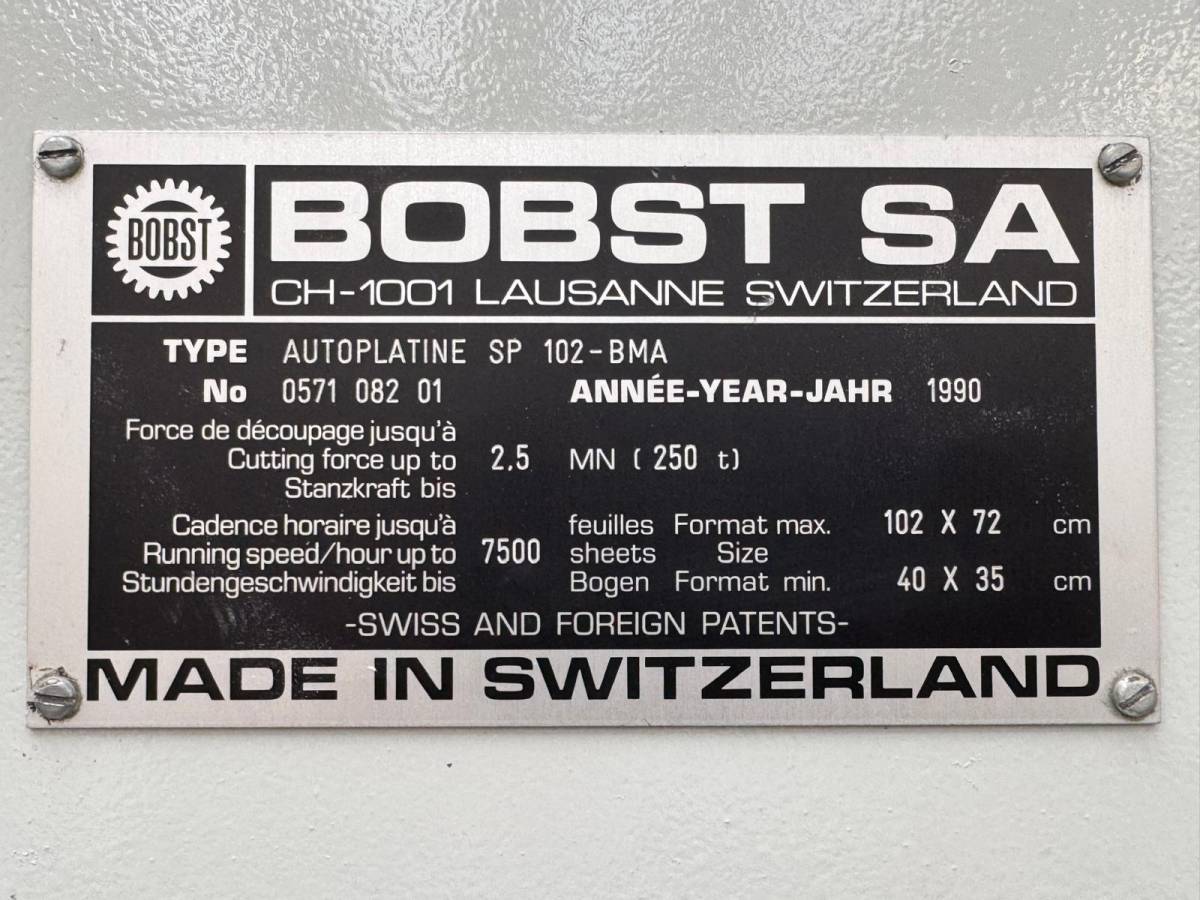

Bobst SP 102 BMA

The machine was selected and carefully inspected by our engineers prior to purchase. Subsequently, it underwent a rigorous overhaul process, based on a well-established working protocol. This process involves disassembly in our specialized workshop, thorough cleaning, repainting of components and units, accurate reassembly, and the overhaul or replacement of all non-conforming or damaged parts and mechanisms according to our long and established experience. Each component is adjusted with centesimal precision to ensure compliance with original factory parameters. Finally, the machine is reassembled and subjected to thorough functionality tests and inspections for the best result according to our high quality standards.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | SP 102 BMA |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 720 x 1020 |

|---|

Accessories

- Machine

- ELEVATED MACHINE Machine elevated 415 mm, included elevation of the steps

- Step

- Centerline for job quick change

- Electronic device for sheet travel control

- Air conditioning for the electrical cabinet

- Gripper bars

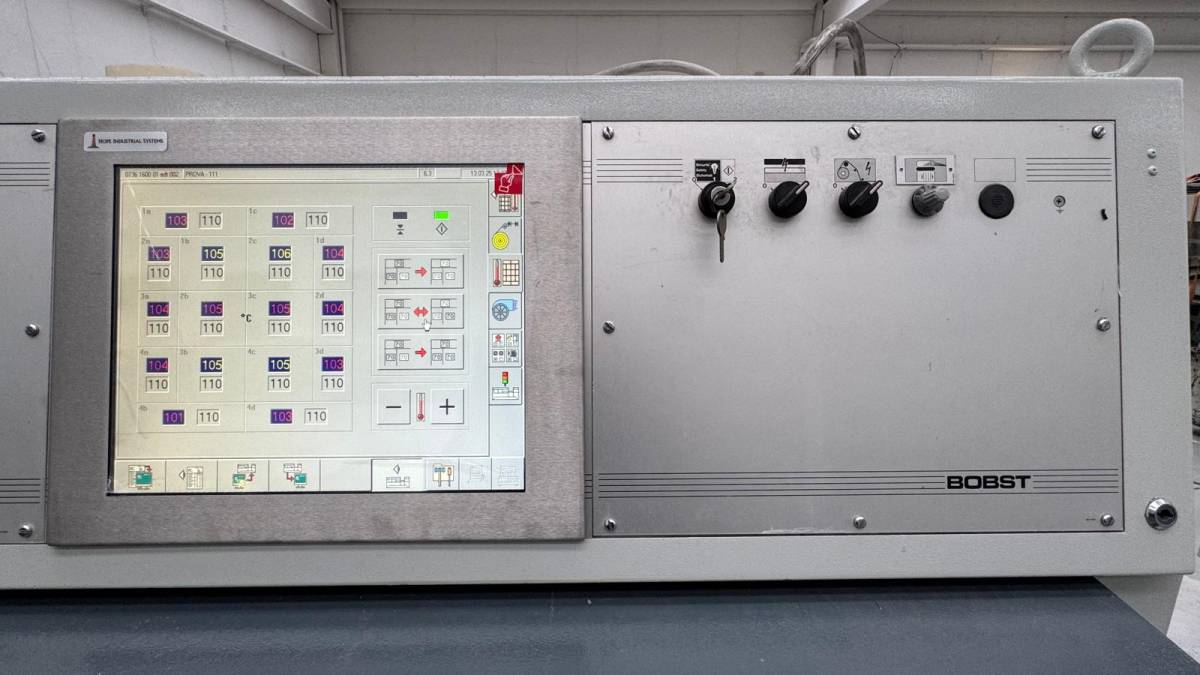

- Bobst-electronic for managing the machine

- Motore principale con variatore di frequenza

- Feeder

- Pile-tray with handle allowing manual lateral correction of the pile during production

- NON-STOP FEEDER MANUAL DEVICE

- Adjustable lateral blowers with Centerline references

- Suction unit with multiple adjusting

- Safety system for lowering the pile try

- Introduction table

- Introduction table covered by antistatic steel stainless plate

- Sheet synchronization adjustable during the machine is running for adapting feeder cycle to platin cycle

- Feed belt slow-down device Ensures smooth arrival of sheets against front lays

- 4 front lays, adjustable in pairs with front register control

- Pull-lay operator side (OS) adjustable according to Centerline, with sheet control

- "Double sheet "detector

- Upper frame with manual lifting device

- Sheet-hold down device (guiding the sheets to front lays)

- Upper transport equipment for paper, paperboard and corrugated board

- Transport belts. With lateral guidance

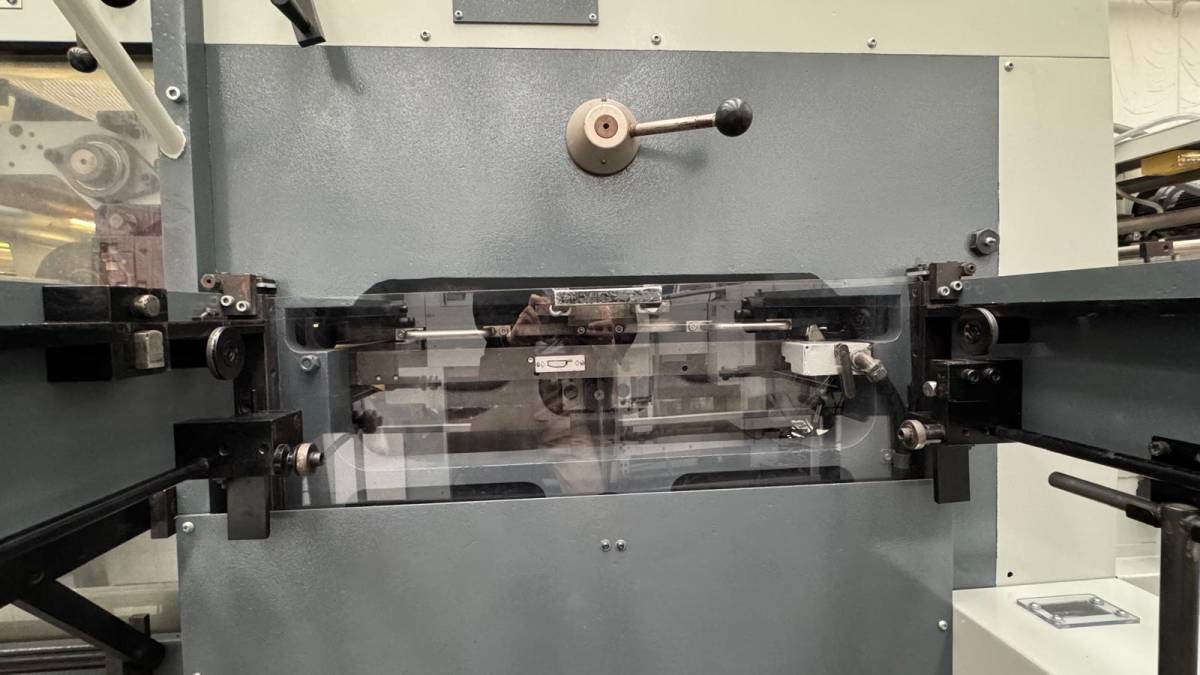

- Platin

- Heated upper platen with 16 heating zones

- Grippers re-opening device

- Equipment centering and locking

- Locking of the chase against the upper beam

- Measurement of the die-cutting force using an electronic probe

- Steel material print supporting plate

- Compensation plate, 3 mm thick (E-52). It is used as a cutting plate for die cutting and as a compensation plate together with the 2.3 mm thick printing plate for printing and embossing

- Honeycomb frame (E-6) Includes a series of cliché fixing accessories. To specify: height of the clichés of 6.35 or 7 mm

- Compensating plate, thickness 2,3 mm (E-62)

- 1 HONEYCOMB FRAME. It includes a series of accessories for fixing the clichés. 1 unit with the basic machine

- Delivery

- Pile tray

- Braking Brush

- Pneumatically controlled adjustable front joggers

- Pneumatically controlled adjustable lateral and front joggers with Centerline marks

- AUTOMATIC NON-STOP BELT. The belt automatically enters on delivery when the pile of sheets is complete. Facilitates the use of non-stop by eliminating the manipulation of the grid. This mat replaces the Non-stop grille (Standard)

- Supplementary equipment "BM"

- Removable tape feeding module. Including a trolley equipped with: 3 shafts for adjusting the advancement of the belts driven by motors

- 2 telescopic reel holder guides

- 2 reel-holder boards

- 2 additional roll-holder axles for preparation outside the machine

- 3 sets of 8 reel holders with 3° combined spindles consisting of: 1 set of narrow rolls; 1 set of medium coils; 1 set of reels with brake

- 30 wide drive rollers, 38 mm wide

- 1 automatic device for putting the platen "on and off" pressure

- 1 Margin line. Facilitates the positioning of clichés

- 1 device for manual tapes introduction (mounted on the autoplaten)

- 1 blower with nozzles to detach the belts after printing (mounted on the platen)

- 1 blower inside the platen to stabilize the sheets of paper before printing or die-cutting (mounted on the platen)

- 1 belts guide on the upper post (mounted on the platen)

- 1 belt tension shaft driven by a motor with air cooling device (mounted on the platen)

- 1 bands break control system with 16 photo-electric cells with lateral adjustment for immediate machine stop in case of band breakage

- 1 lateral evacuation device for metal band with rotary brushes at variable speed depending on the advancement of the belts (mounted on the platen)

- 1 longitudinal belts cutting device (mounted on the platen)

- Security

- Operator safety devices

- Gripper Bar Chain Slip Clutch

- Handling of the diecutting equipment

- Emergency Stops

- Photoelectric cell safety barriers located at the feeder and at the delivery

Machine overview

| Year | 1990 |

|---|---|

| Serial Number | 057108201 |

| N.of working hours | 57626 |

Conditions Overview

“EXTRA” Accessories Overview

- ELEVATED MACHINE Machine elevated 415 mm, included elevation of the steps

- 1 HONEYCOMB FRAME. It includes a series of accessories for fixing the clichés. 1 unit with the basic machine

- AUTOMATIC NON-STOP BELT. The belt automatically enters on delivery when the pile of sheets is complete. Facilitates the use of non-stop by eliminating the manipulation of the grid. This mat replaces the Non-stop grille (Standard)

Reference Overview

| Reference | 20035829 |

|---|---|

| Visible | Testable in production at Sbm a Robecco sul Naviglio (MI) |

| Availability | Ready for delivery |

Note:

TOP Machine; Print test possible with your jobs by appointment

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset