Used Post-Press machines for Sale

BOBST HEIDELBERG POLAR STAHL

Enlarge

Enlarge

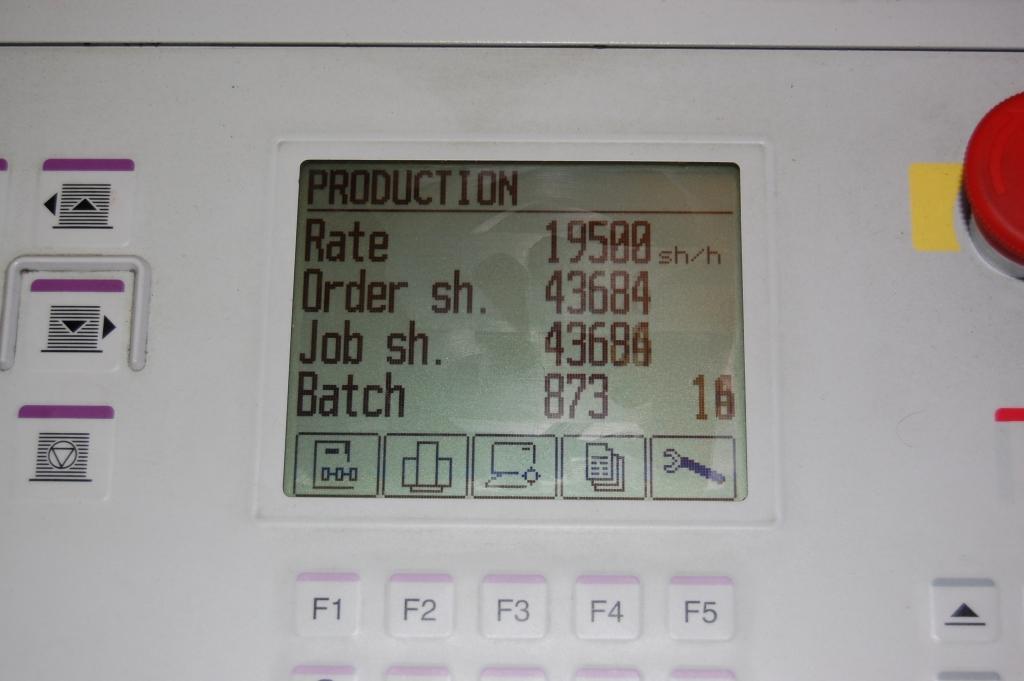

Heidelberg TH82 6/4/2 Rotary

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Heidelberg |

|---|---|

| Model | TH82 6/4/2 Rotary |

| Type | Folding/Piegatrice |

TECHNICAL DATA

| Max sheet size | 820 x 1280 |

|---|

Accessories

- Feeder

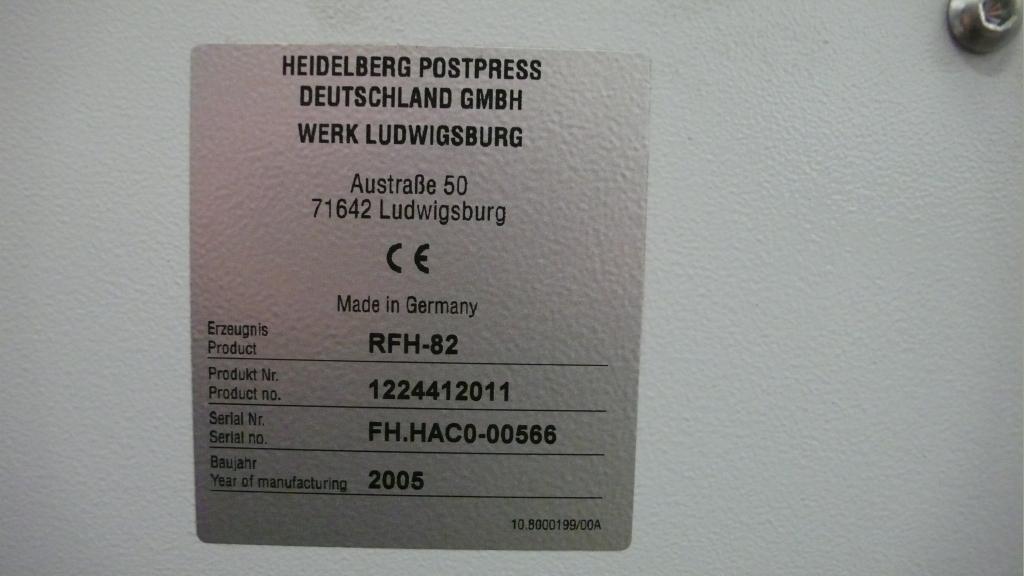

- Rotary RFH feeder

- Printing Units

- 1° station with 6 pockets automatized Kat.II with High Performance Kit

- 2° station 4 pockets automatized +High Performance

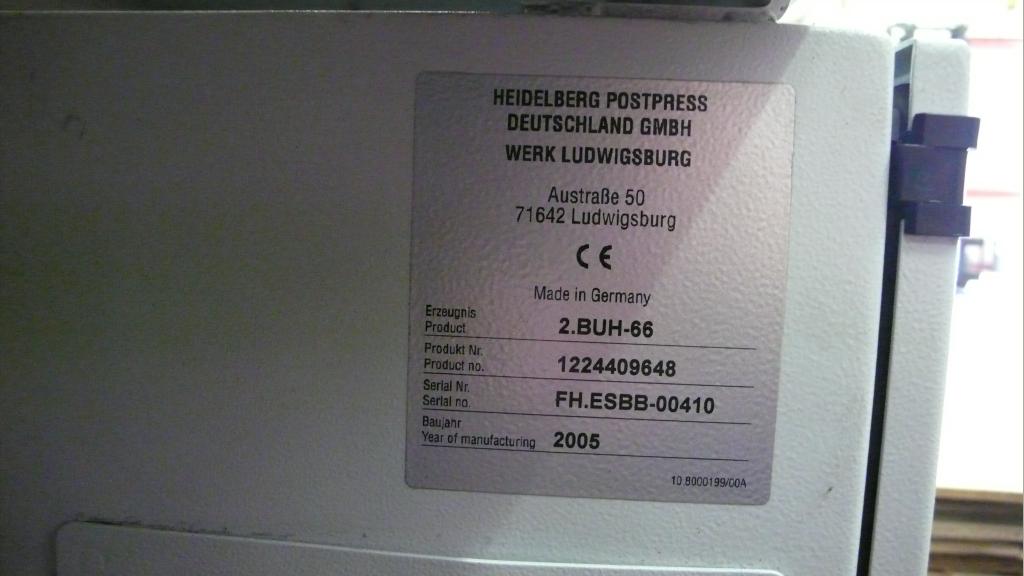

- 3° station with 2 pockets automatized 66 cm. Kat.II with High Performance Kit

- Delivery

- Orizontal delivery SBP.D

Machine overview

| Year | 2005 |

|---|---|

| Serial Number | 1224412555 |

“EXTRA” Accessories Overview

- Rotary RFH feeder

- 1° station with 6 pockets automatized Kat.II with High Performance Kit

- 2° station 4 pockets automatized +High Performance

- 3° station with 2 pockets automatized 66 cm. Kat.II with High Performance Kit

- Orizontal delivery SBP.D

Reference Overview

| Reference | 19016601 |

|---|---|

| Visible | Camporese Rebuilding Center of Limena (PD) |

| Availability | Immediately |

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset