Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

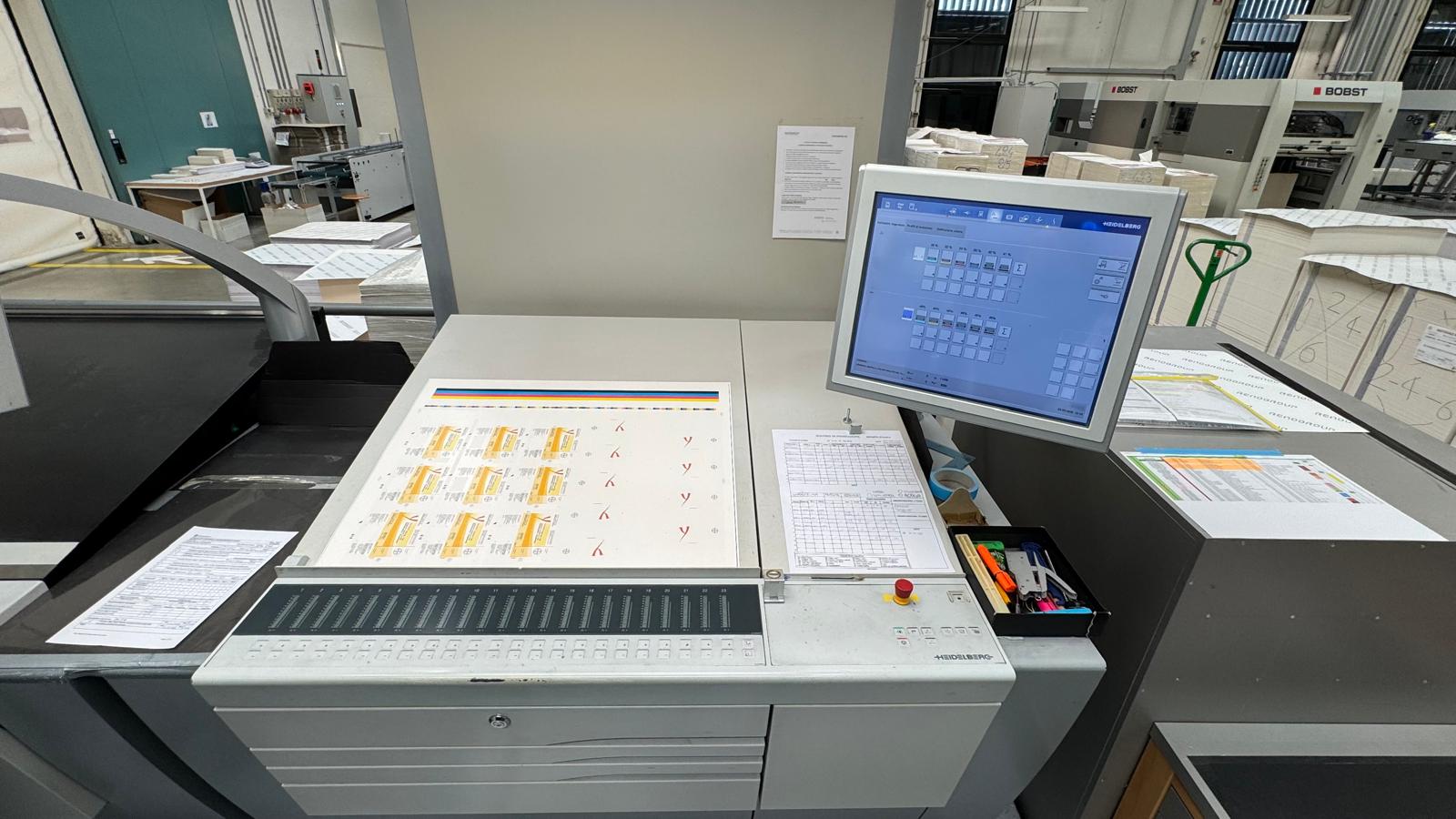

Heidelberg XL75-6 P2+LX 3 (F) Hybrid

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Heidelberg |

|---|---|

| Model | XL75-6 P2+LX 3 (F) Hybrid |

| Type | Sheetfed Offset/Offset a foglio |

TECHNICAL DATA

| Max sheet size | 600,5 x 750 |

|---|

Accessories

- Console

- Prinect Press Center console touch screen, axial, circumferential and diagonal register remote control, ink ductors rotation control, job memorization

- Prinect Press Center MasterLevel

- Prinect Press Center Color Assistant Pro

- Press Center InstantStar

- Prinect Press Center IntantGate

- Image Control: Spectrophotometric quality control on all the surfice of the printed sheet

- Feeder

- Pile height sensor

- Pneumatic side register control with integrated auto cleaning and double shee control with direct system

- Non-Stop on feeder

- Double sheet detector - pulling device

- StaticStar Compact : No. 2 Eltex ion blowers on feeder, antistatic bars on feeder and delivery

- Printing Units

- Alcolor Vario System damping

- Double diameter impression cylinders

- Double diameter transfer cylinder between printing units, with Air Transfer System with possibility to adjust automatically it based on thickness of material to print

- Roller wash-up device controlled by Prinect Press Center

- Blanket and impression cylinders automatic washing devices by Prinect Press Center

- Suction brush on 1 printing unit

- Autoplate PRO: Automatic plate change

- CombiStar PRO CAN : Technotrans ink temp control combined with damping refrigeration + Alcosmart

- Auto Protect. Protective fluid management system for the X PU inking rollers

- Blowing bar (anti-emulsion) on the inking units, recommended for UV and hybride X PU machines

- 6/0 ; 1/5 Fully Automatic perfecting device

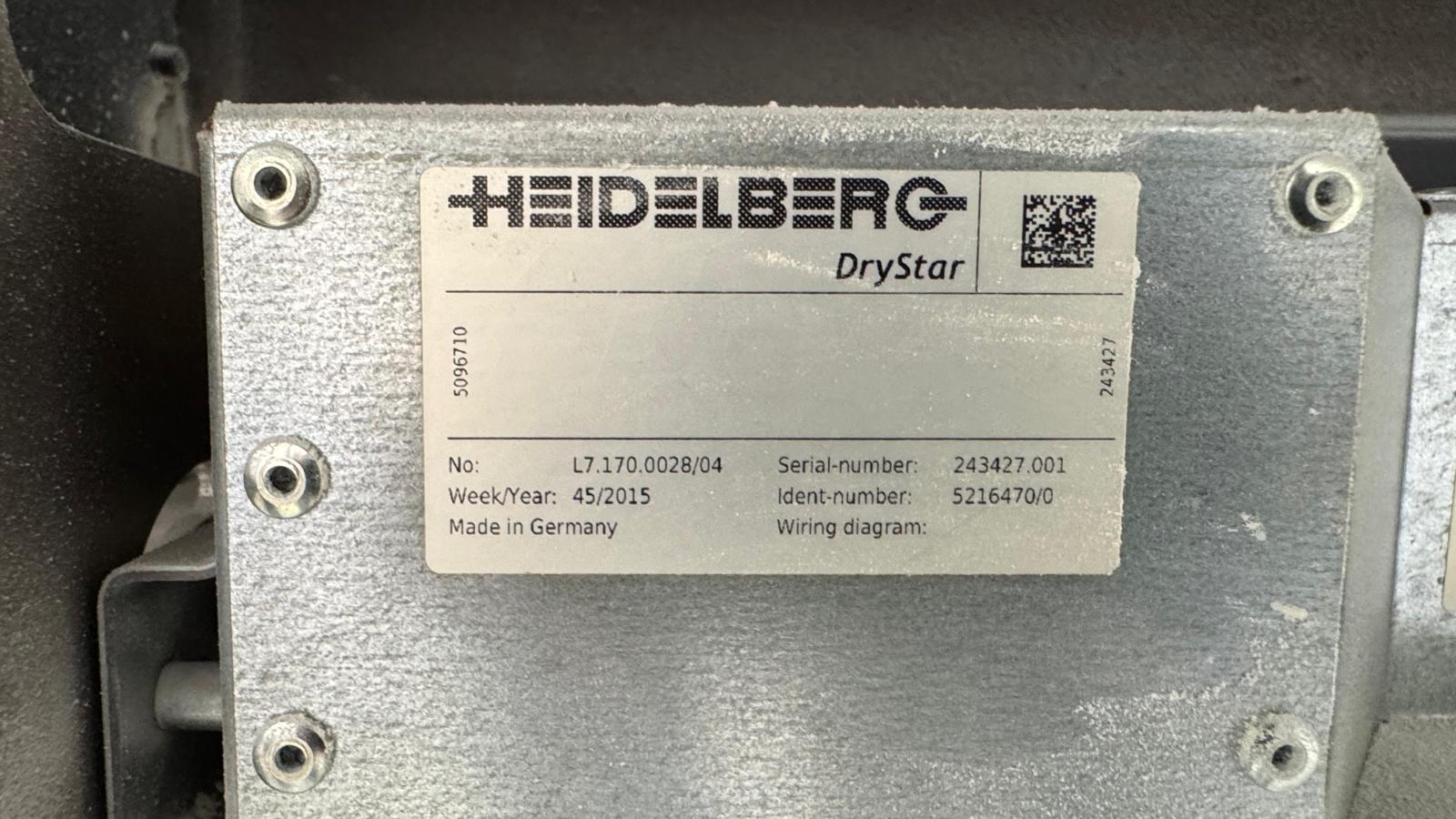

- N.ro 3 x DryStar IST/UV Interdeck CAN to put in all transfer positions (full flexibility)

- Ink.mate Technotrans Ink agitators

- Varnishing units

- Varnishing unit 550 L./H., with cooking register, Tresu pressurized chambered doctor blade system, with anilox roller

- Coating Star : heat coater system

- One additional camera not pressured

- Nro 4 anilox rollers: 120 lines (paper); 100 lines (UV); 80 lines (cardboard); 60 lines (cardboard);

- Delivery

- Extended Delivery (240 cm / X3)

- Non-Stop in delivery

- PowderStar Weko AP 500 CANopen

- CleanStar Compact : filter for powder spray suction

- DryStar Combination UV CAN with 4 modules (IR/HA + HA + EOP UV + Cold Air Module ) Water Cooled

- Peripherals

- ScrollStar : Atlas Copco compressor

- AirStar Pro : central air box water cooled

- Various

- 15.000 speed/h

- Technotrans Beta.t : Water refrigeration cabin for UV Dryer

- Elevated 550 mm

- Intercom : Microphone communication system

Machine overview

| Year | 2016 |

|---|---|

| Serial Number | LS001264 |

| N.of Impressions | 115 mio. |

“EXTRA” Accessories Overview

- Prinect Press Center Color Assistant Pro

- Press Center InstantStar

- Prinect Press Center IntantGate

- Image Control: Spectrophotometric quality control on all the surfice of the printed sheet

- Non-Stop on feeder

- Double sheet detector - pulling device

- Suction brush on 1 printing unit

- Autoplate PRO: Automatic plate change

- Auto Protect. Protective fluid management system for the X PU inking rollers

- Blowing bar (anti-emulsion) on the inking units, recommended for UV and hybride X PU machines

- 6/0 ; 1/5 Fully Automatic perfecting device

- N.ro 3 x DryStar IST/UV Interdeck CAN to put in all transfer positions (full flexibility)

- Ink.mate Technotrans Ink agitators

- Varnishing unit 550 L./H., with cooking register, Tresu pressurized chambered doctor blade system, with anilox roller

- Coating Star : heat coater system

- One additional camera not pressured

- Nro 4 anilox rollers: 120 lines (paper); 100 lines (UV); 80 lines (cardboard); 60 lines (cardboard);

- Extended Delivery (240 cm / X3)

- Non-Stop in delivery

- PowderStar Weko AP 500 CANopen

- CleanStar Compact : filter for powder spray suction

- DryStar Combination UV CAN with 4 modules (IR/HA + HA + EOP UV + Cold Air Module ) Water Cooled

- AirStar Pro : central air box water cooled

- Technotrans Beta.t : Water refrigeration cabin for UV Dryer

- Elevated 550 mm

- Intercom : Microphone communication system

Reference Overview

| Reference | 24036459 |

|---|---|

| Availability | 01/01/2026 |

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset