Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

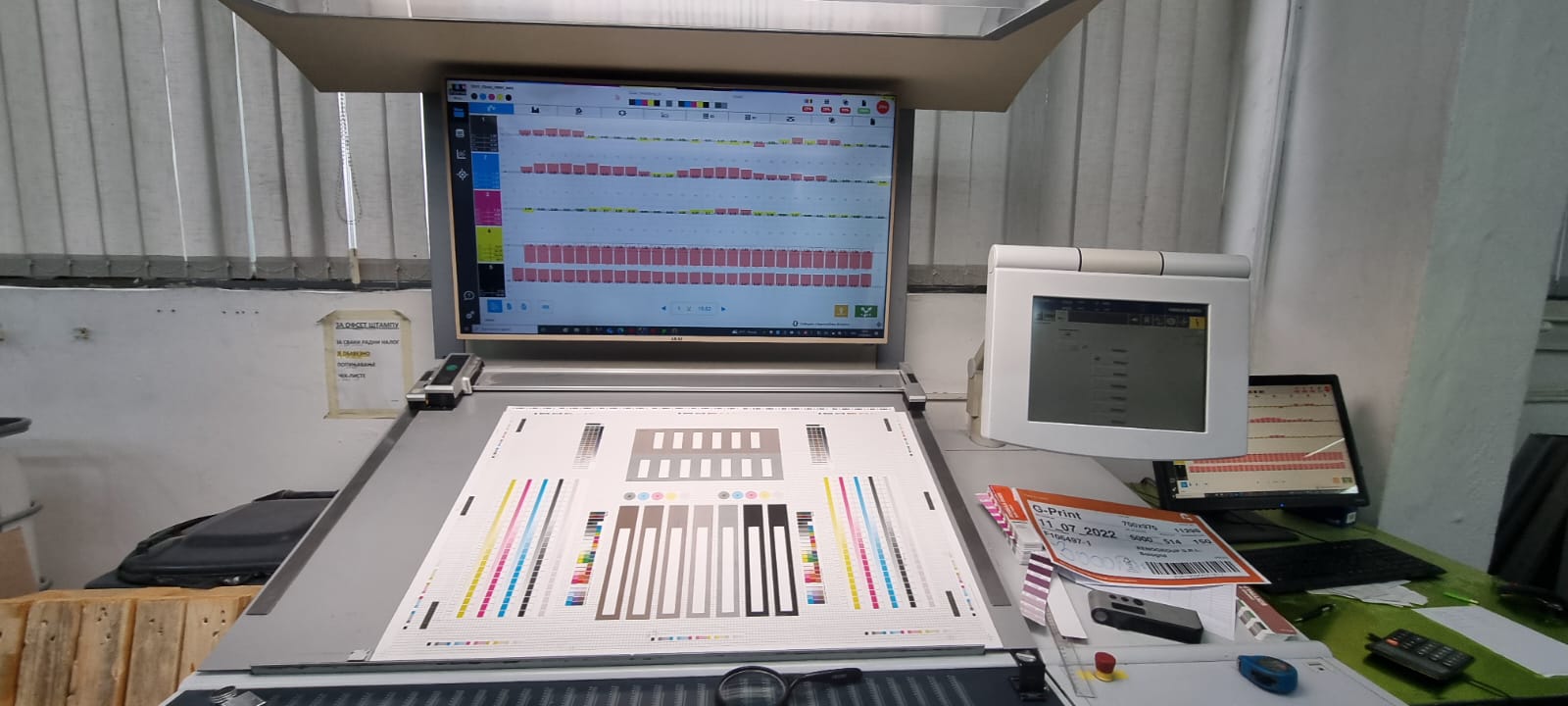

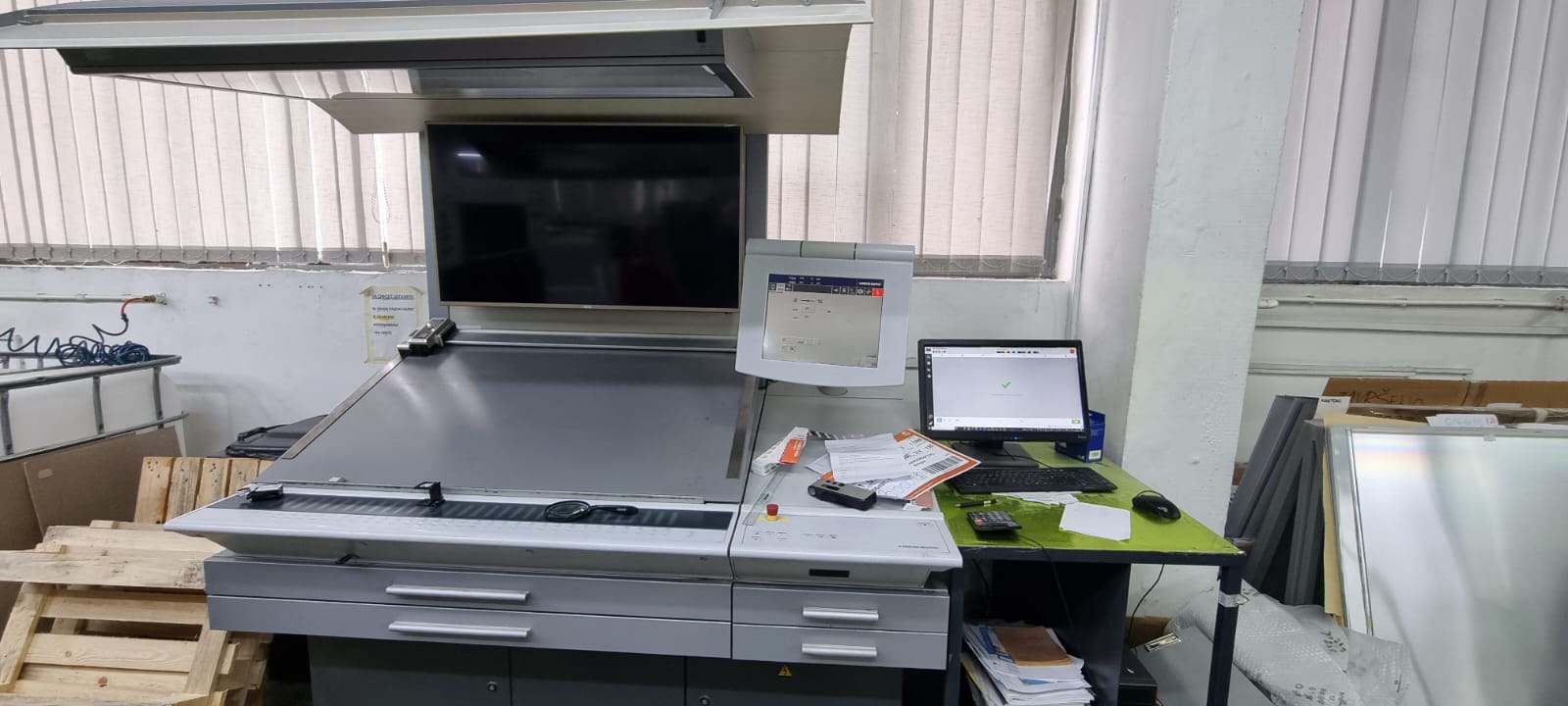

Heidelberg CD102-5 L

The machine was selected and carefully inspected by our engineers prior to purchase. Subsequently, it underwent a rigorous overhaul process, based on a well-established working protocol. This process involves disassembly in our specialized workshop, thorough cleaning, repainting of components and units, accurate reassembly, and the overhaul or replacement of all non-conforming or damaged parts and mechanisms according to our long and established experience. Each component is adjusted with centesimal precision to ensure compliance with original factory parameters. Finally, the machine is reassembled and subjected to thorough functionality tests and inspections for the best result according to our high quality standards.

MACHINE SPECIFICATION

| Manufacturer | Heidelberg |

|---|---|

| Model | CD102-5 L |

| Type | Sheetfed Offset/Offset a foglio |

TECHNICAL DATA

| Max sheet size | 720 x 102 |

|---|---|

| Min sheet size | 280 x 420 |

| Max print size | 710 x 1020 (Autoplate) |

| Material Thickness | 0,03 / 1 mm |

| Plate size | 790 x 1030 (Autoplate) |

Accessories

- Console

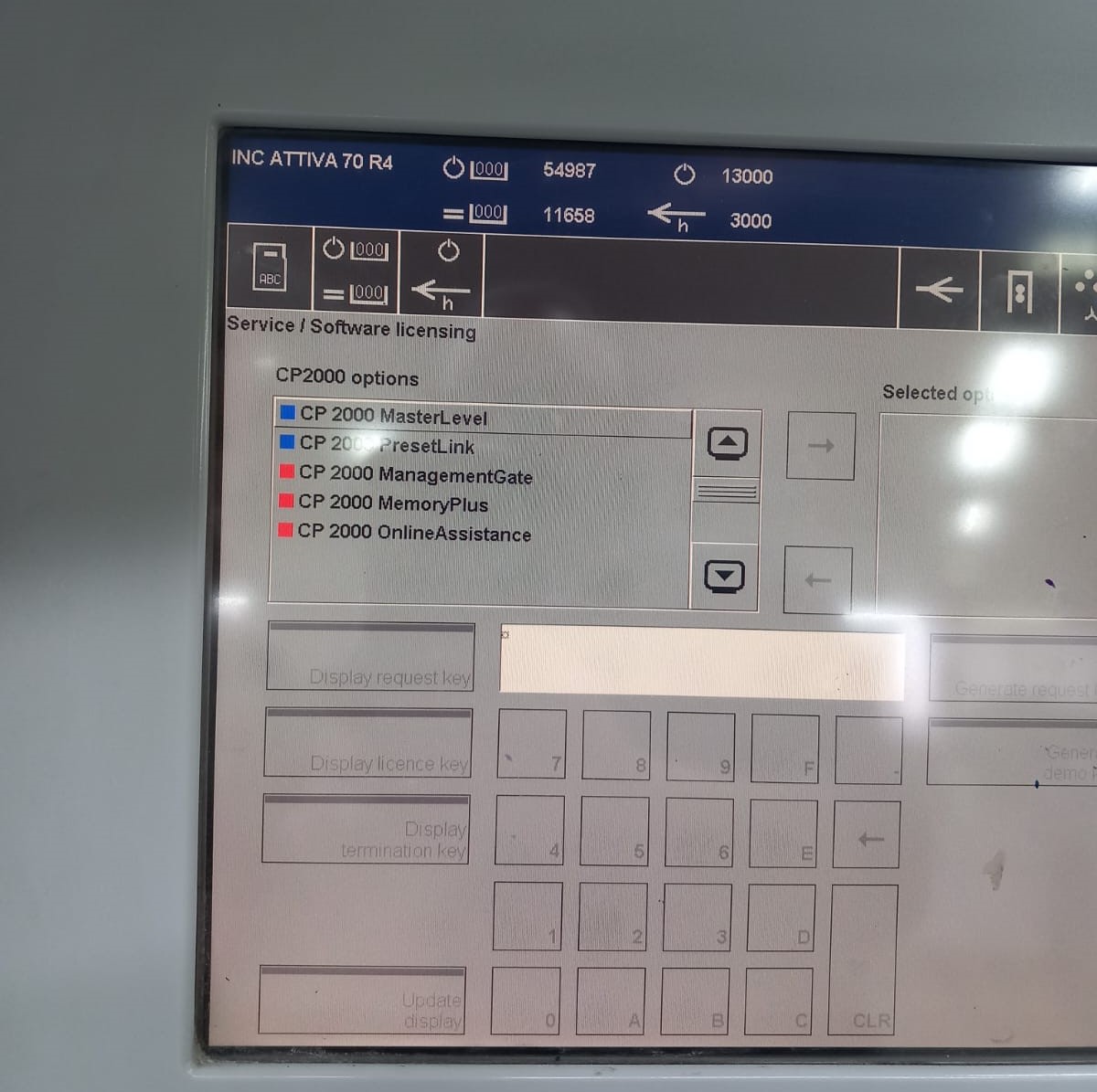

- CP 2000 console touch screen, axial, circumferential and diagonal register remote control, ink ductors rotation control, job memorization

- CP 2000 MasterLevel

- CP 2000 Preset Link

- SpectroDrive Techkon Service calibration with remote ink adjusting

- Feeder

- Electronic side lays control

- Preset : automatic size adjusting on feeder and delivery on CP 2000

- Additional double sheet electronic detection

- No. 2 Eltex ion blowers on feeder

- Eltex antistatic on feeder

- Printing Units

- Air Transfer System Venturi

- Roller wash-up device controlled by CP 2000

- Modular blanket cylinder washing device by CP 2000

- Modular impression cylinder washing device by CP 2000

- Autoplate

- Alcolor damping

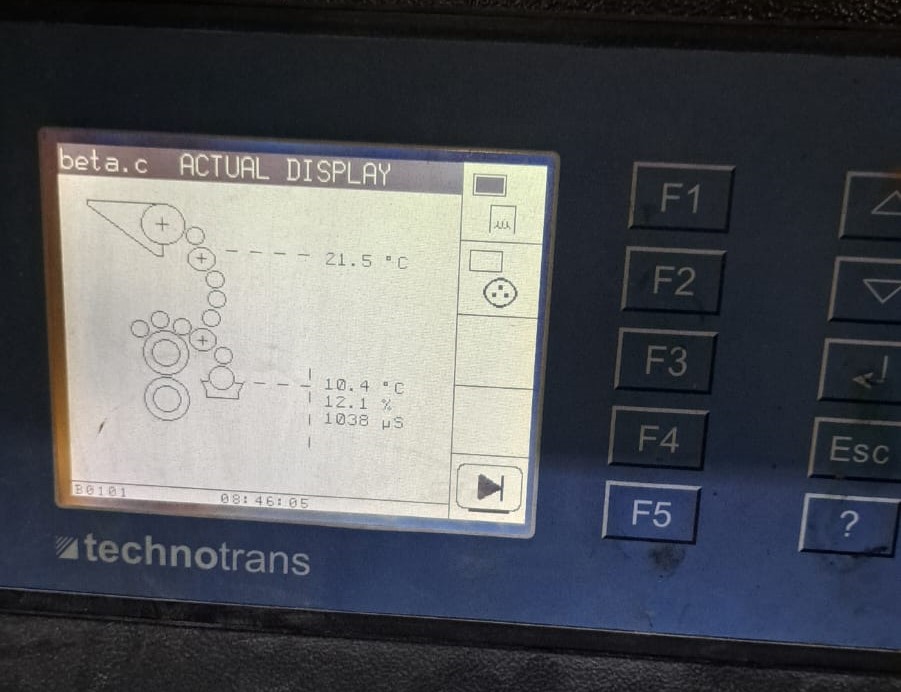

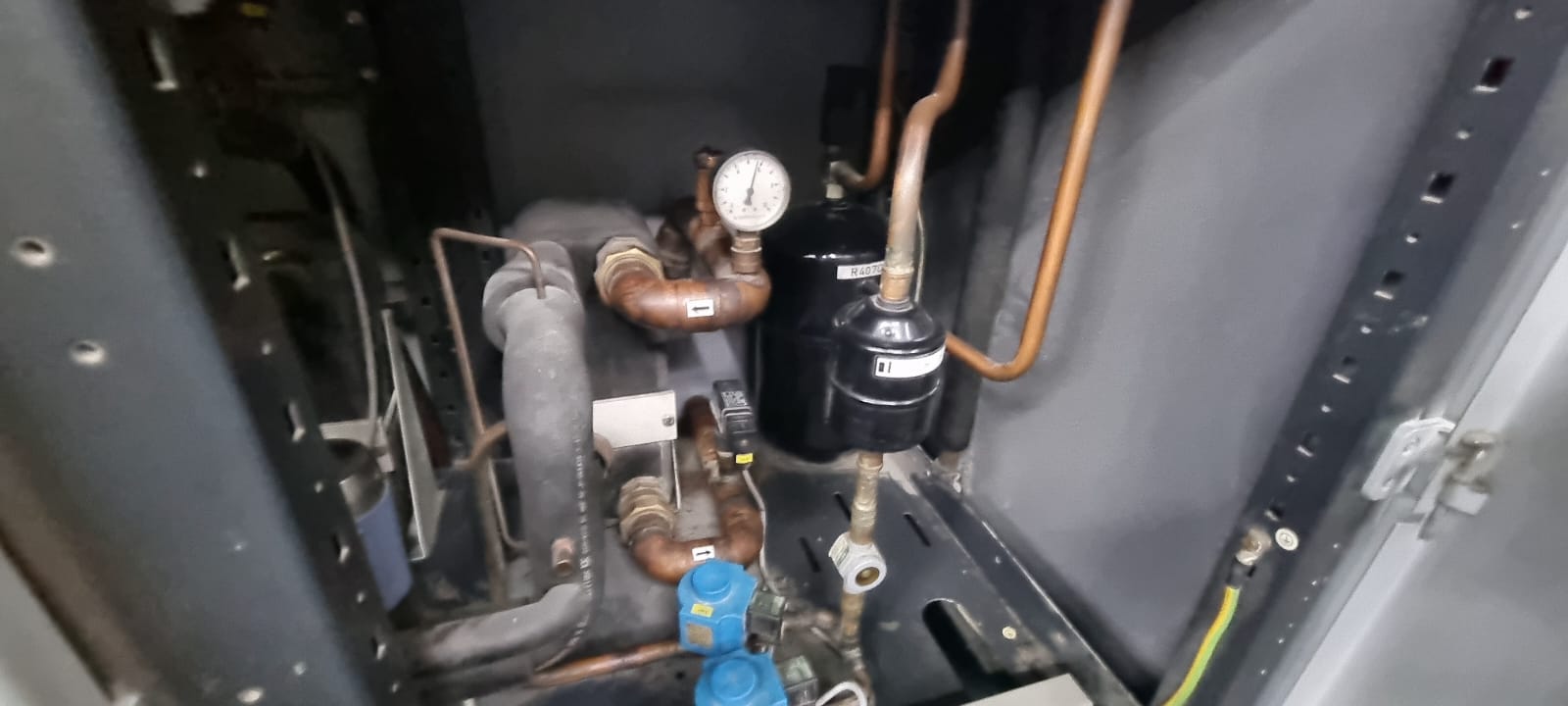

- CombiStar: Technotrans ink temp control combined with damping refrigeration + Alcosmart

- All cylinders chromed

- WashStar : automatic cleaning of catch pans

- Inking unit with remote distributor-roller adjustment

- Varnishing units

- Varnishing unit, Tresu chambered doctor blade system, with anilox roller

- TRESU AQUA L10 Coating Circulator

- Delivery

- CleanStar : filter for powder spray suction

- Grafix Exactronic Duo Plus powder spray

- Non-Stop in delivery

- Sheet slow-down device suction drum 10 mm

- DryStar 2000 : Dryer HR-IR + HL-Preset

- Peripherals

- ScrollStar : Atlas Copco compressor

- AirStar : central air box air cooled

- Various

- 15.000 speed/h

Machine overview

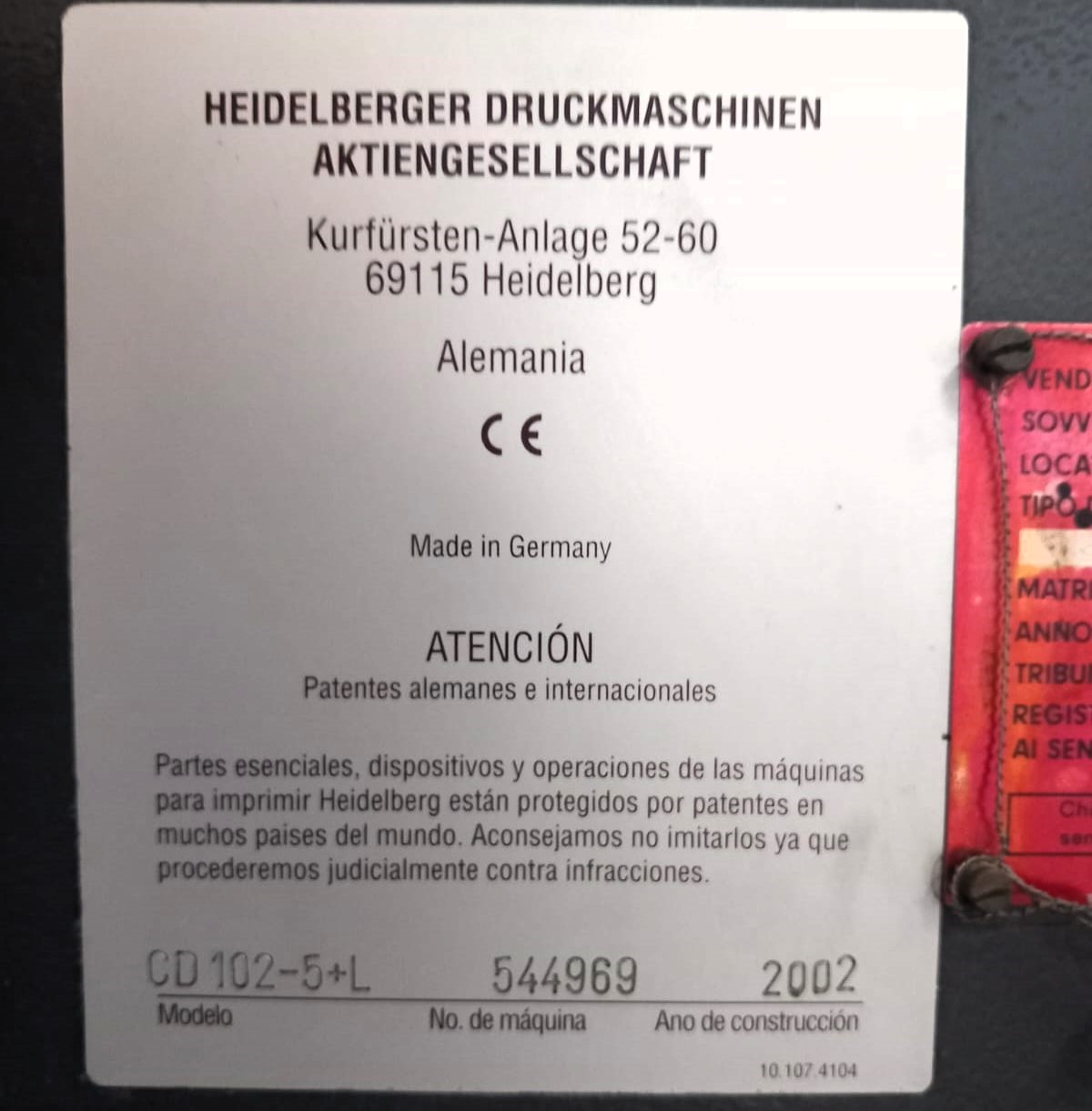

| Year | 2002 |

|---|---|

| Serial Number | 544969 |

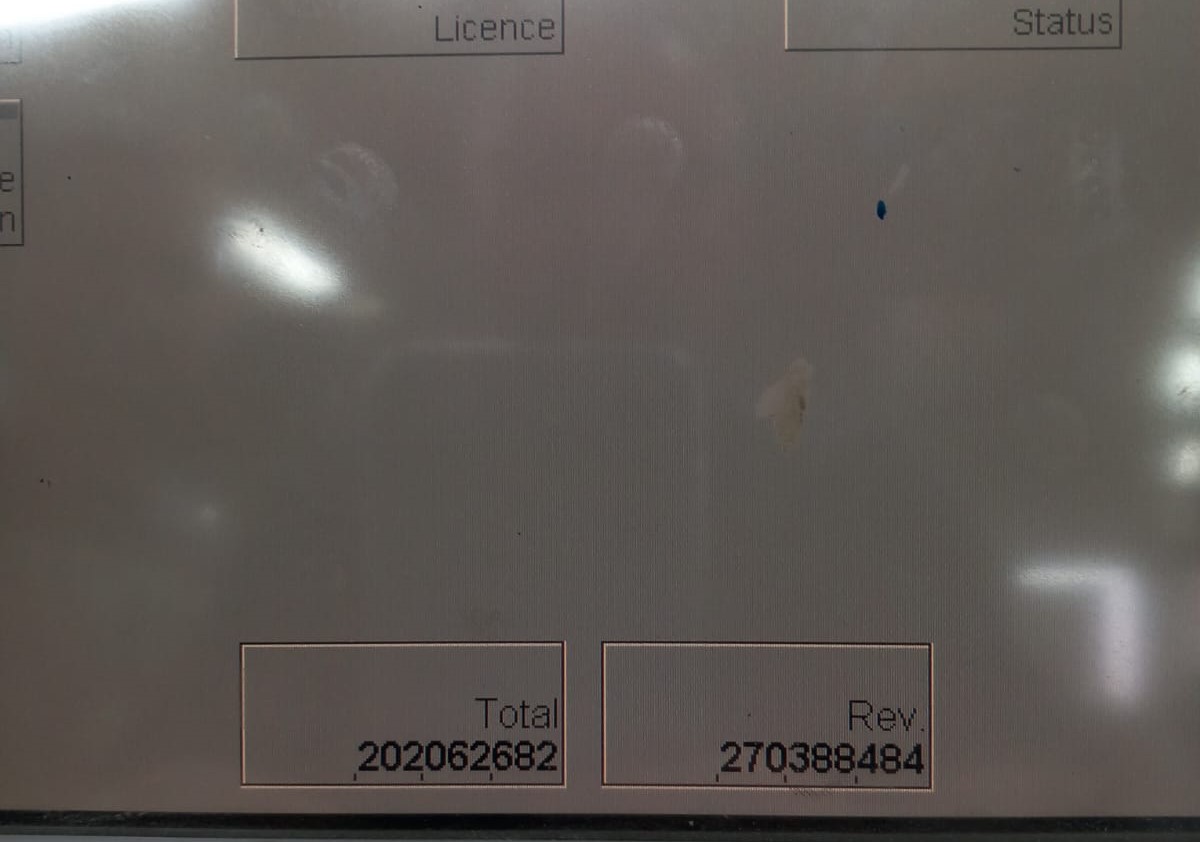

| N.of Impressions | 200.0 mio. |

“EXTRA” Accessories Overview

- CP 2000 Preset Link

- SpectroDrive Techkon Service calibration with remote ink adjusting

- Additional double sheet electronic detection

- No. 2 Eltex ion blowers on feeder

- Eltex antistatic on feeder

- CombiStar: Technotrans ink temp control combined with damping refrigeration + Alcosmart

- All cylinders chromed

- WashStar : automatic cleaning of catch pans

- Inking unit with remote distributor-roller adjustment

- Varnishing unit, Tresu chambered doctor blade system, with anilox roller

- TRESU AQUA L10 Coating Circulator

- CleanStar : filter for powder spray suction

- Grafix Exactronic Duo Plus powder spray

- Non-Stop in delivery

- Sheet slow-down device suction drum 10 mm

Reference Overview

| Reference | 24036458 |

|---|---|

| Visible | In production |

| Availability | Immediately |

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset