Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

Heidelberg SM102-10 P

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Heidelberg |

|---|---|

| Model | SM102-10 P |

| Type | Sheetfed Offset/Offset a foglio |

TECHNICAL DATA

| Max sheet size | 720 x 1020 |

|---|---|

| Min sheet size | 280 x 240 (400 x 420 with Perfecting) |

| Max print size | 710 x 1020 |

| Material Thickness | 0,03 / 0,8 mm - (0,6 mm perfecting) |

| Plate size | 770 x 1030 (790 x 1030 Autoplate) |

Accessories

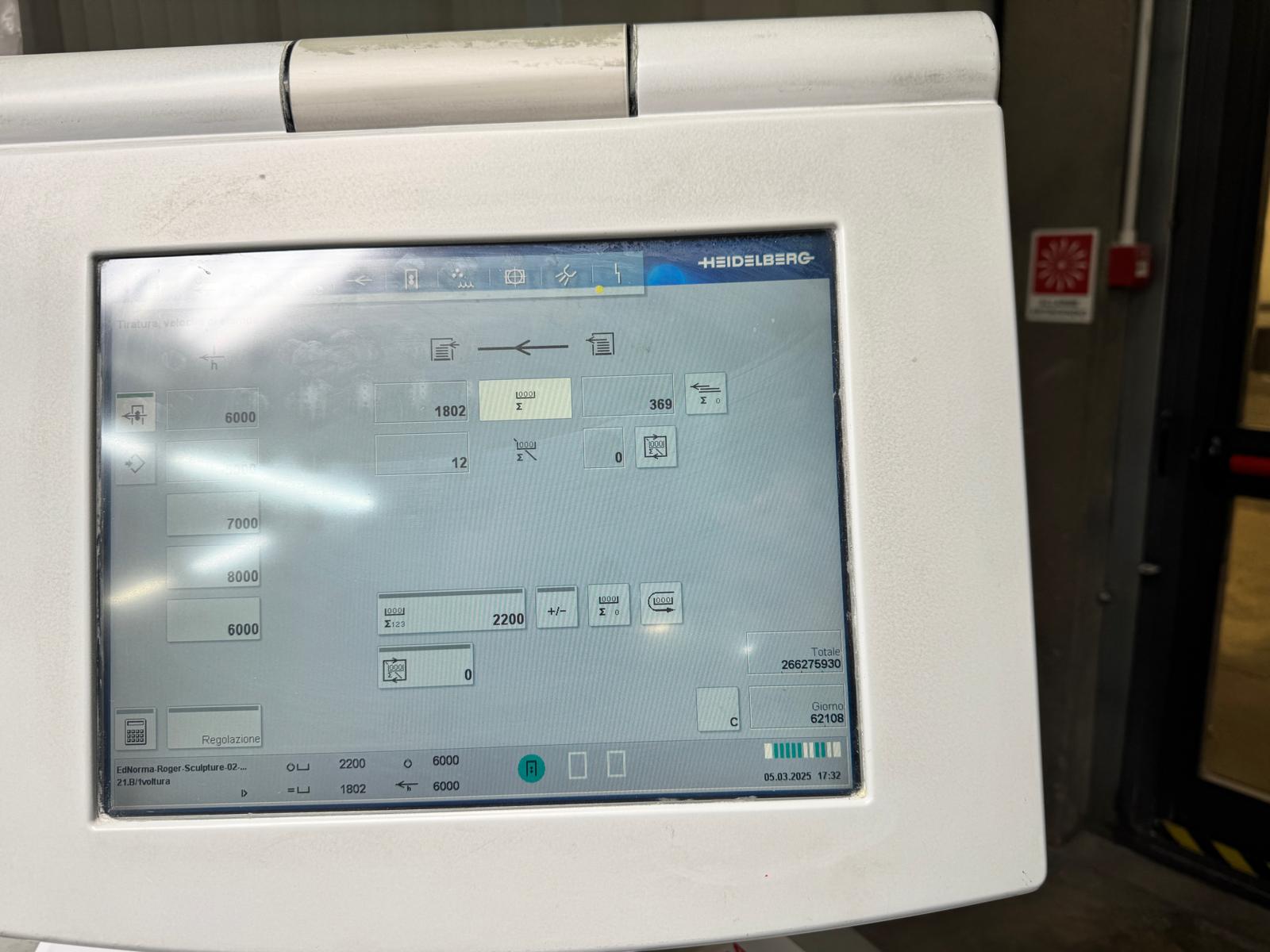

- Console

- CP 2000 console touch screen, axial, circumferential and diagonal register remote control, ink ductors rotation control, job memorization

- CP 2000 MasterLevel

- CP 2000 Preset Link

- CP 2000 Tandem Wash : impression cylinder washing device by CP 2000

- Feeder

- Preset Plus Feeder

- Head feeder 3 more suctions for paper transport

- Front sensor on flap of the feeder

- Slow down : system to slow the sheet down then 65% on feeder

- Ultrasonic sensor double-sheet control

- Suction belt feeder with 3 sections of transport of sheets to the frontal registers

- Pneumatic side register control with integrated auto cleaning and double sheet control with direct system

- Ultrasonic double-sheet control

- Multiple-sheet detector/ tear-off

- Multiple sheet control/Forwarding roller

- No. 2 Eltex ion blowers on feeder

- Printing Units

- Roller wash-up device controlled by CP 2000

- Modular blanket cylinder washing device by CP 2000

- Alcolor Vario System damping

- CombiStar CAN : Technotrans ink temp control combined with damping refrigeration + Alcosmart

- 10/0 ; 5/5 Semi-automatic Perfecting

- WashStar : automatic cleaning of catch pans

- Inking unit with remote distributor-roller adjustment

- Autoplate

- Delivery

- Preset Plus Delivery : a lot of preset functions and memorization, aereodinamic grippers system, slow down system by CP 2000, panel in delivery

- PowderStar Duo Plus CAN : Grafix Exactronic Duo Plus

- CleanStar Plus : filter for powder spray suction

- Non-Stop in delivery

- PowderStar Plus Can : Grafix Exactronic Plus powder spray

- Peripherals

- AirStar : central air box air cooled

- ScrollStar : Atlas Copco compressor

- AirStar : central air box water cooled

- Various

- Intercom system : microphone communication system

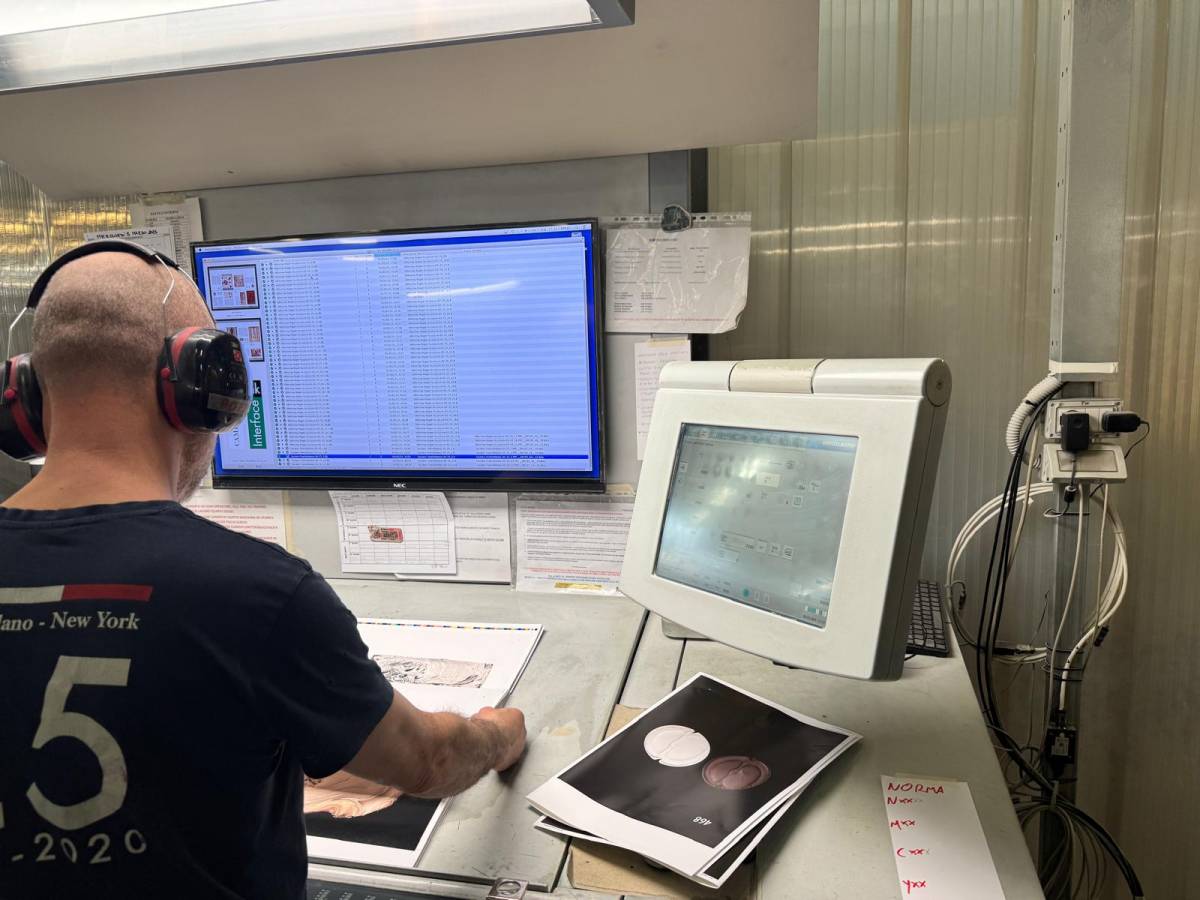

Machine overview

| Year | 2006 |

|---|---|

| Serial Number | 547810 |

| N.of Impressions | 266 mio. |

“EXTRA” Accessories Overview

- CP 2000 Preset Link

- CP 2000 Tandem Wash : impression cylinder washing device by CP 2000

- Preset Plus Feeder

- Ultrasonic double-sheet control

- Multiple-sheet detector/ tear-off

- Multiple sheet control/Forwarding roller

- Alcolor Vario System damping

- CombiStar CAN : Technotrans ink temp control combined with damping refrigeration + Alcosmart

- WashStar : automatic cleaning of catch pans

- Inking unit with remote distributor-roller adjustment

- Preset Plus Delivery : a lot of preset functions and memorization, aereodinamic grippers system, slow down system by CP 2000, panel in delivery

- PowderStar Duo Plus CAN : Grafix Exactronic Duo Plus

- CleanStar Plus : filter for powder spray suction

- Non-Stop in delivery

- PowderStar Plus Can : Grafix Exactronic Plus powder spray

- Intercom system : microphone communication system

Reference Overview

| Reference | 19033962 |

|---|---|

| Visible | In production |

| Availability | Immediately |

Note:

The machine was fully overhauled by Camporese at 175 million impressions. Since then, it has been consistently and regularly maintained by Camporese

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset