Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

Bobst SP 104 E

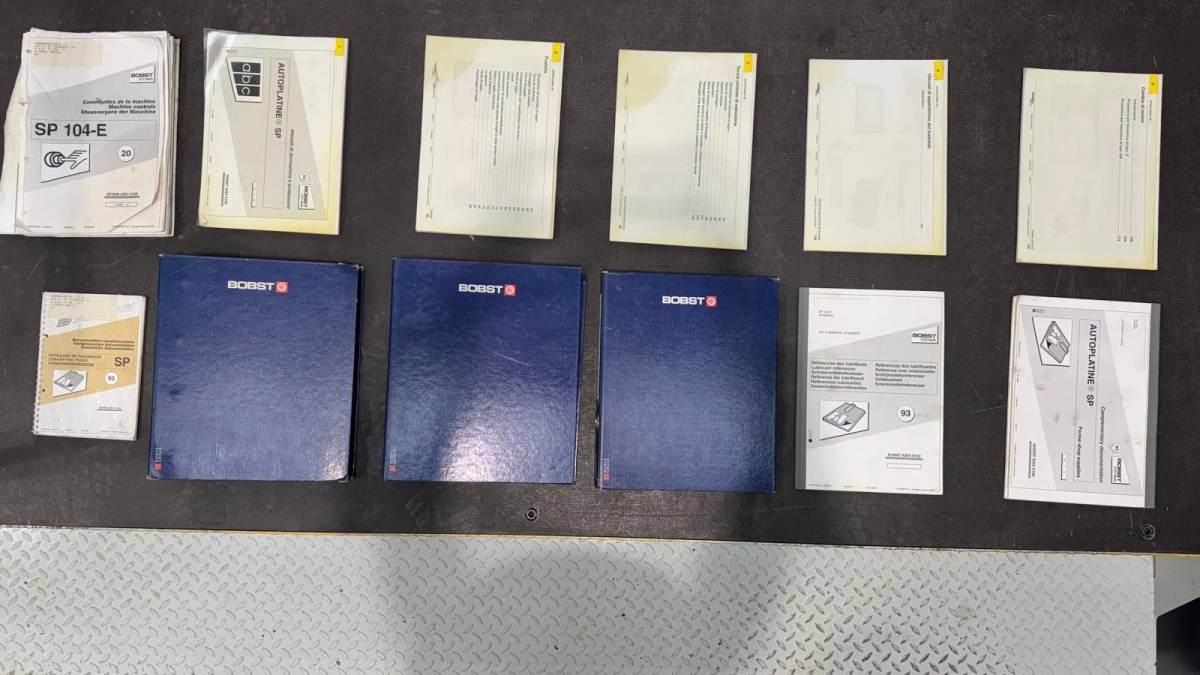

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

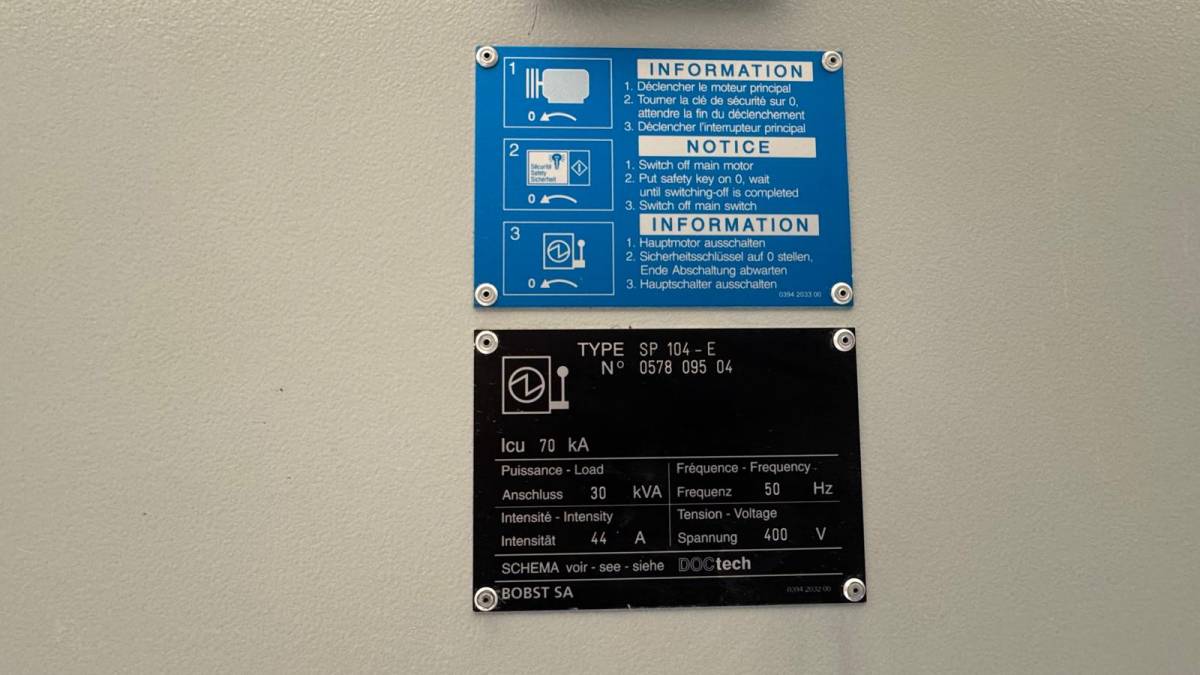

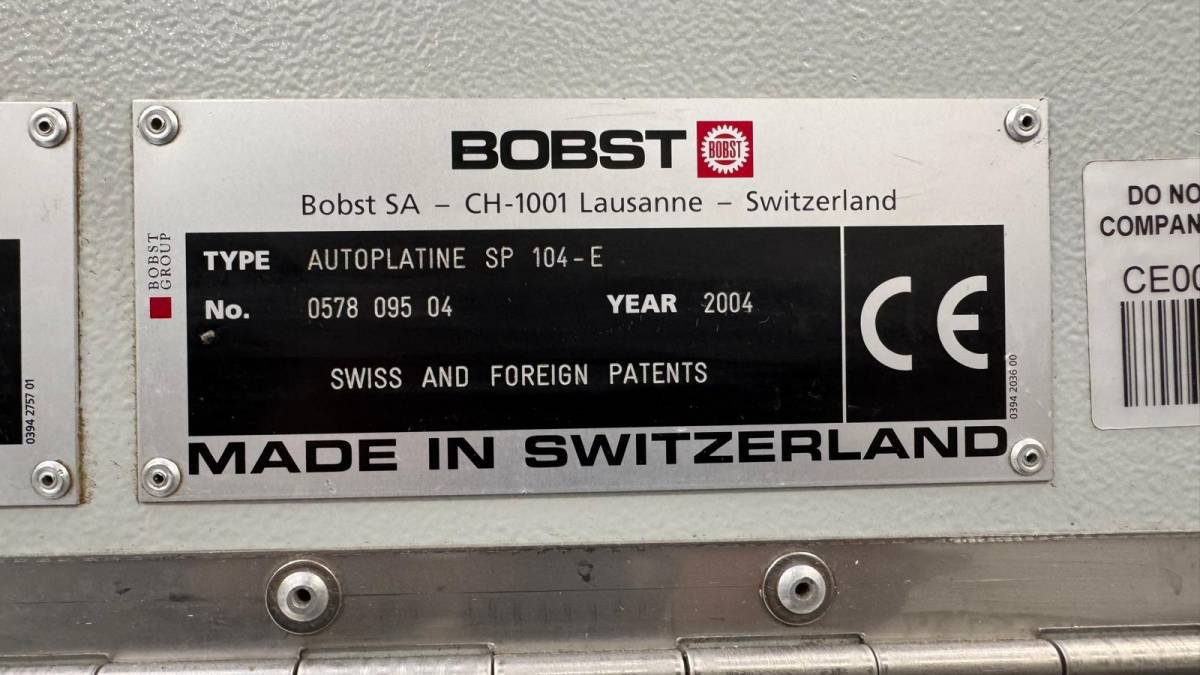

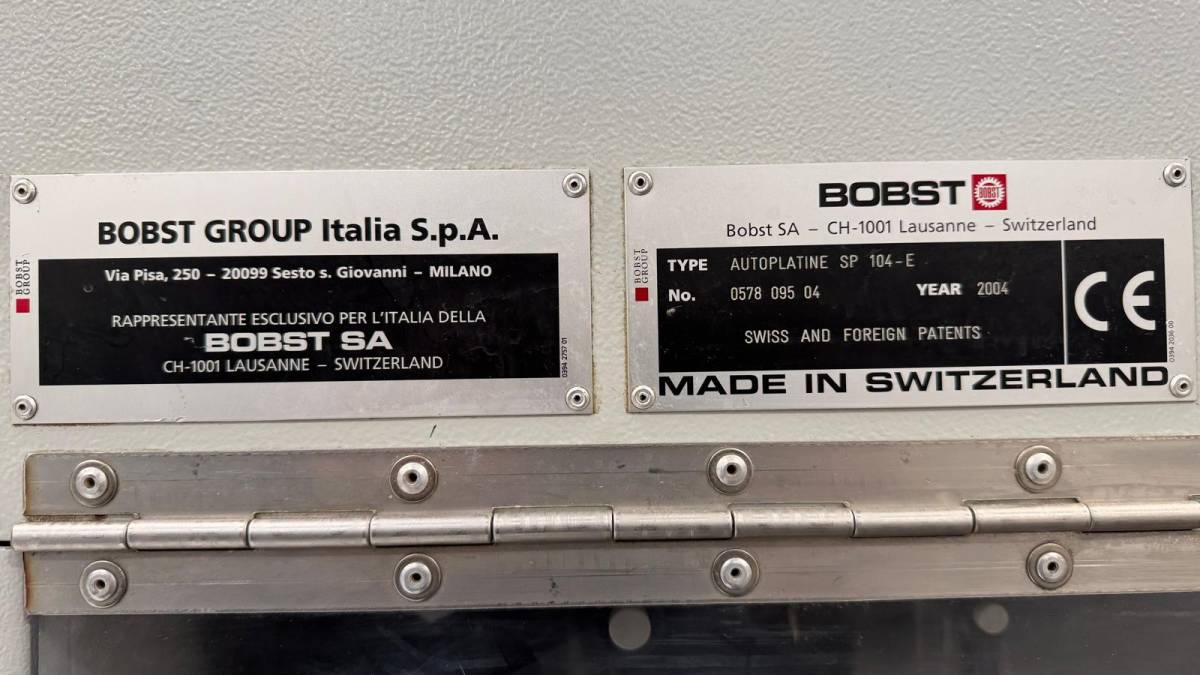

| Manufacturer | Bobst |

|---|---|

| Model | SP 104 E |

| Type | Die Cutting/fustellatrici |

TECHNICAL DATA

| Max sheet size | 1040 x 740 |

|---|---|

| Min sheet size | 350 x 400 |

Accessories

- Machine

- Platform with safety barrier

- Centerline system for quick job changeover

- Electronic device for sheet travel control

- Adjustable centering at the stripping

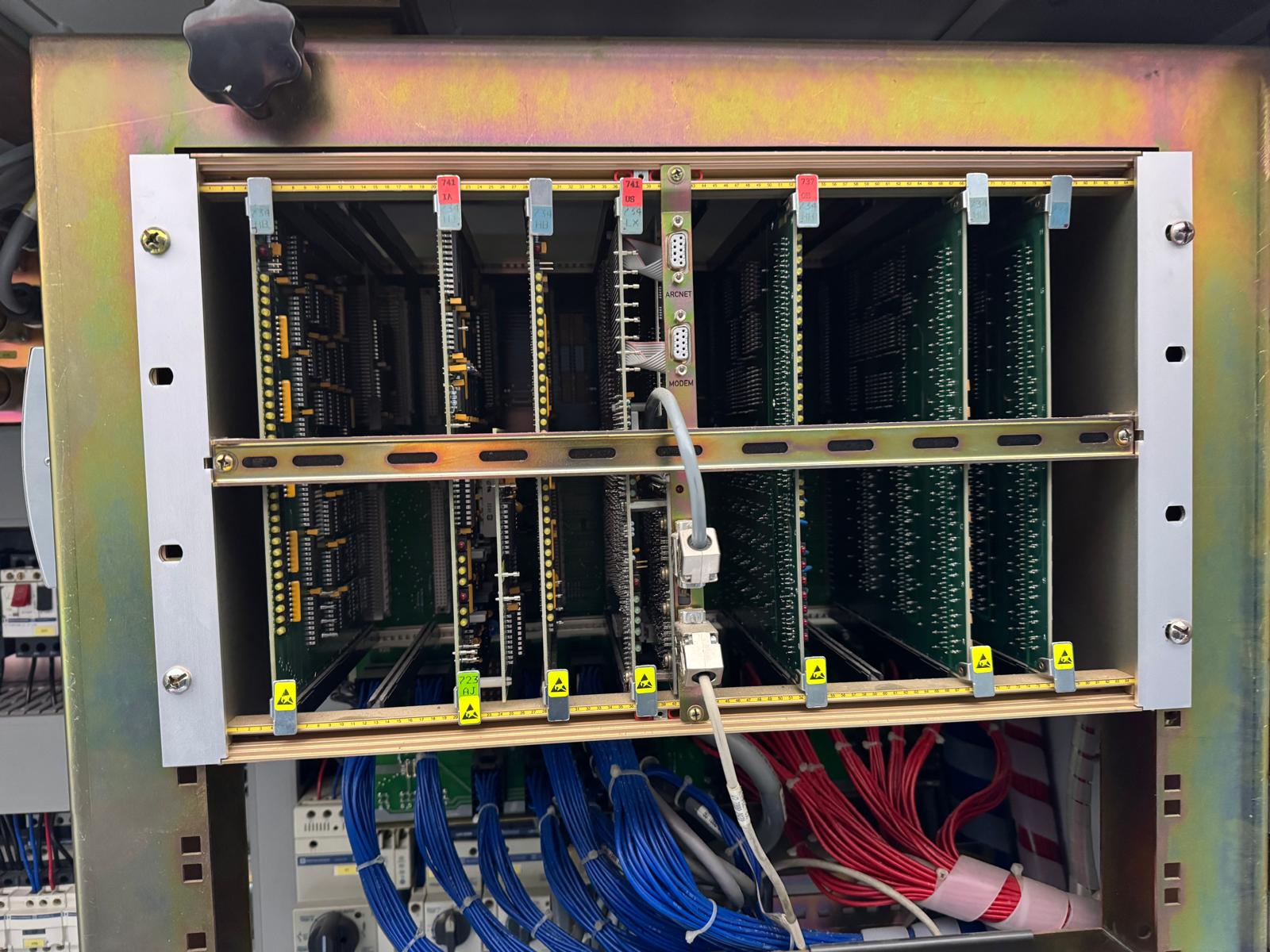

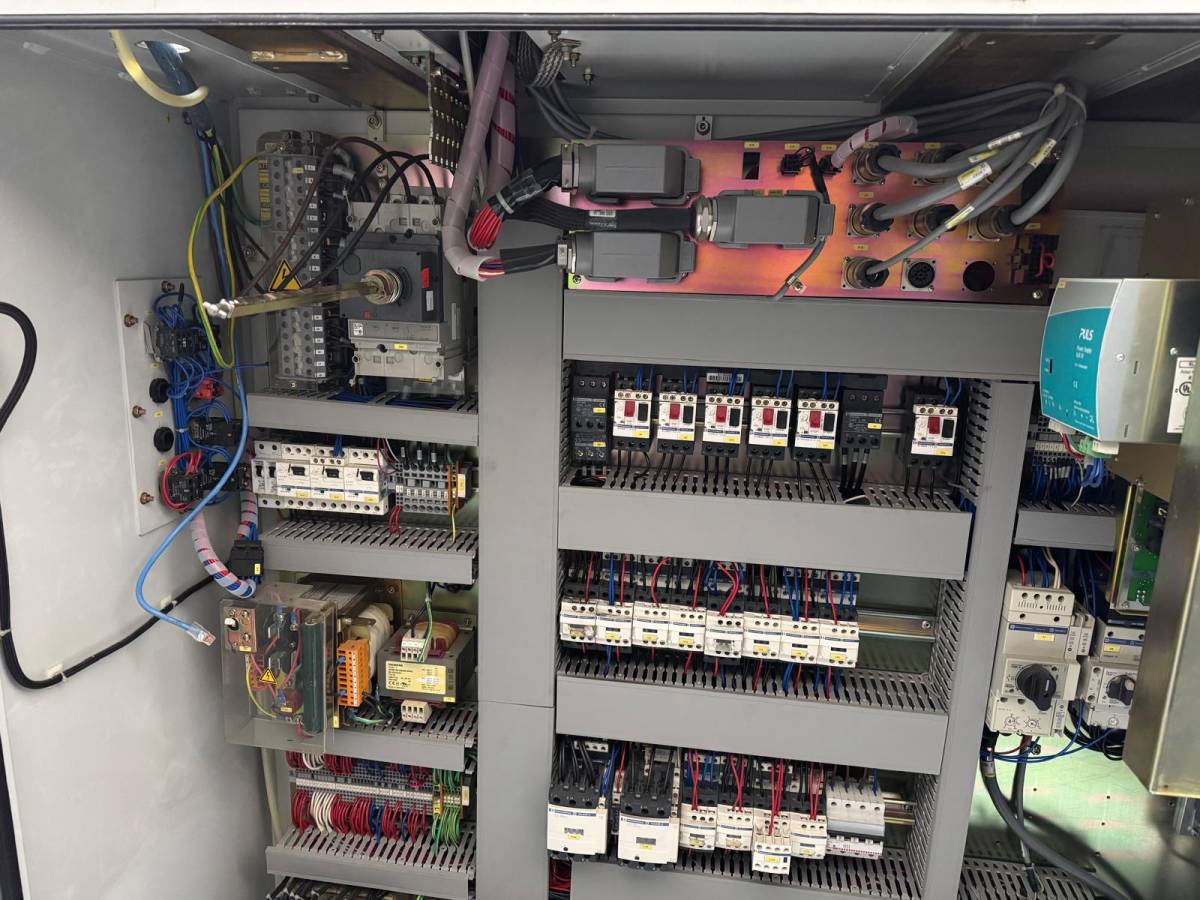

- Air conditioning for the electrical cabinet

- Gripper bars

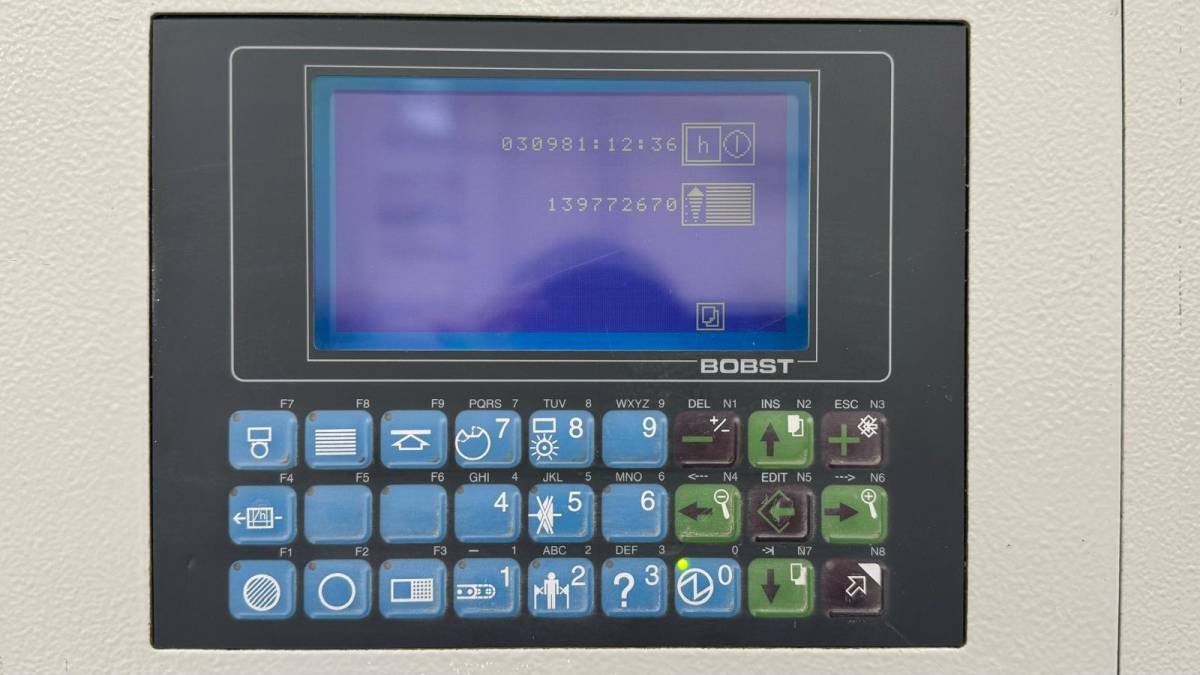

- C.U.B.E. (Control Unit Bobst Electronic) for machine management

- Main motor with frequency variator

- Feeder

- Pile-tray with handle allowing manual lateral correction of the pile during production

- Pile height control at the front edge thanks to a photoelectric cell

- Adjustable lateral blowers with Centerline references

- Pile rear guide (OS and OOS sides)

- Safety system for lowering the pile try

- Suction unit with multiple adjusting

- C-4 NON-STOP FEEDER MANUAL DEVICE

- C-8 VERTICAL POSITIONING OF THE SUCTION UNIT. Eliminates manual interventions to compensate for the flatness of the pile shape

- Introduction table

- Covered with an anti-static stainless steel plate

- Inlet table feeder

- 4 front lays, adjustable in pairs with front register control

- 1 Pull-lay operator side (OS) adjustable according to Centerline, with sheet control

- 1 Double sheet detector

- Support plates at entry of platen station

- 1 Sheet-hold down device (guiding the sheets to front lays)

- 1 Upper frame with manual lifting device

- 1 Upper transport equipment for paper, paperboard and corrugated board

- 4 Transport belts. With lateral guidance

- C-5 CONTROLLABLE SHEET ARRIVAL FOR PERFECT SYNCHRONIZATION OF SHEET ARRIVAL AND REDUCTION OF MACHINE STOPPAGES

- Platin

- Grippers re-opening device

- Die-cutting device without band of gripper grip

- Equipment centering and locking

- Locking of the chase against the upper beam

- Measurement of the die-cutting force with strain gauge

- Resocell: synthetic material supporting plate. Thickness 22.5 mm

- 1 Upper chase with quick locking: fixed bottom (E-3) Plate, thickness 2 mm and make-ready protection plate of syntetic material, 1 mm thickness

- 1 Cutting plate (E-4)

- E-5 COMPENSATION PLATE 4 mm thickness. it's useful for thin plate for repetetive work

- E 55 ADJUSTABLE SUPPORTING PLATE CENTERINGS : micromeric screws allow fine adjustment of counters mounted on the cutting plate with respect to the die (+/- 0,9 mm lengthwise and crosswise.

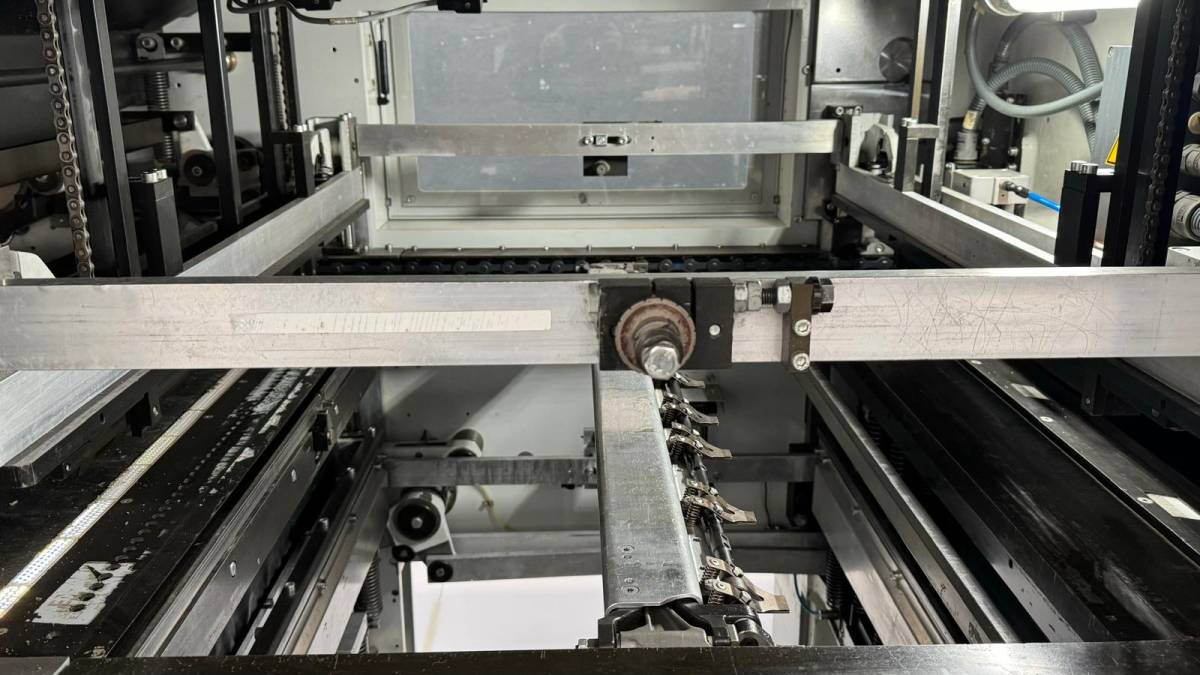

- Stripping Station

- 3 drawer frame system

- 1 Upper Stripping Frame (F-2)

- 1 Upper stripping equipment (F-21) required to create a waste stripping tool, including crossbars, clamps, stripper holders and stripping pins of 3, 5 and 10 mm of diameter

- 1 Fastening equipment for stripping die (F-22)

- 1 Central drawer frame (F-71)

- 1 Fastening equipment stripping table (F-75)

- 1 lower pull-out frame (F-8)

- 1 Lower stripping equipment (F-81) Equipment for waste stripping including crossbars, pins and supports

- F-31 1 UPPER PULL-OUT FRAME QUICK LOCK. It reduces stripping tool assembly times; the quick-closing device allows the tool to be changed in the machine)

- F-35 1 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- F-72 1 CENTRAL PULL-OUT FRAME QUICK LOCK

- F-76 1 FASTENING EQUIPMENT FOR STRIPPING TABLE ON CENTRAL PULL-OUT FRAME QUICK LOCK It allows to equip a stripping table to install it on central pull-out frame quick-lock

- Delivery

- Pile tray in delivery

- Adjustable rear and side joggers with Centerline marks

- 1 Braking brush

- Pneumatically controlled adjustable front joggers

- 1 Pushes the sheets down, ensuring good stacking

- G-5 AUTOMATIC NON-STOP ON DELIVERY

- Conformity to standards and security

- Operator safety devices

- Gripper Bar Chain Slip Clutch

- Gripper bar chain locking device

- Handling of the diecutting equipment

- Emergency Stops

Machine overview

| Year | 2004 |

|---|---|

| Serial Number | 057809504 |

| N.of working hours | 30981 |

“EXTRA” Accessories Overview

- C-4 NON-STOP FEEDER MANUAL DEVICE

- C-8 VERTICAL POSITIONING OF THE SUCTION UNIT. Eliminates manual interventions to compensate for the flatness of the pile shape

- C-5 CONTROLLABLE SHEET ARRIVAL FOR PERFECT SYNCHRONIZATION OF SHEET ARRIVAL AND REDUCTION OF MACHINE STOPPAGES

- E-5 COMPENSATION PLATE 4 mm thickness. it's useful for thin plate for repetetive work

- E 55 ADJUSTABLE SUPPORTING PLATE CENTERINGS : micromeric screws allow fine adjustment of counters mounted on the cutting plate with respect to the die (+/- 0,9 mm lengthwise and crosswise.

- F-31 1 UPPER PULL-OUT FRAME QUICK LOCK. It reduces stripping tool assembly times; the quick-closing device allows the tool to be changed in the machine)

- F-35 1 FASTENING EQUIPMENT FOR UPPER PULL-OUT FRAME QUICK LOCK DEVICE FOR STRIPPING (TO FIX STRIPPING TOOL TO THE UPPER PULL-OUT FRAME QUICK LOCK)

- F-72 1 CENTRAL PULL-OUT FRAME QUICK LOCK

- F-76 1 FASTENING EQUIPMENT FOR STRIPPING TABLE ON CENTRAL PULL-OUT FRAME QUICK LOCK It allows to equip a stripping table to install it on central pull-out frame quick-lock

- G-5 AUTOMATIC NON-STOP ON DELIVERY

Reference Overview

| Reference | 25036496 |

|---|---|

| Visible | In production |

| Availability | Immediately |

Note:

Die cutting test possible with your jobs by appointment

MACHINE VIDEOS

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset