Used Presses machines for Sale

Heidelberg KBA Komori Manroland BOBST POLAR STAHL

Enlarge

Enlarge

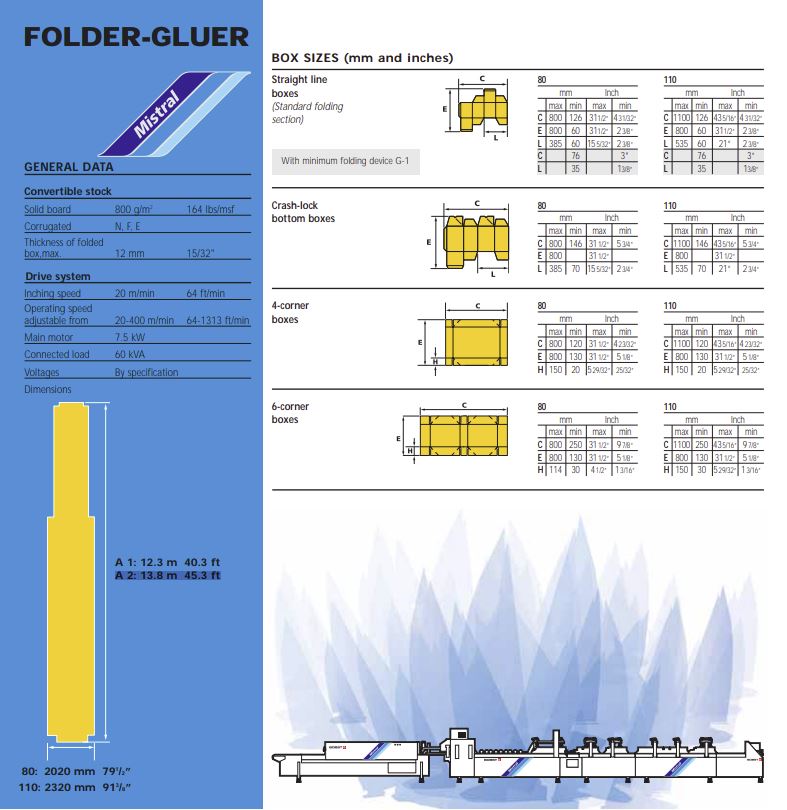

Bobst MISTRAL 110 A2 CS

The machine was selected and carefully inspected by our engineers prior to purchase.

MACHINE SPECIFICATION

| Manufacturer | Bobst |

|---|---|

| Model | MISTRAL 110 A2 CS |

| Type | Folding Carton Gluing/Piegaincolla |

TECHNICAL DATA

Accessories

- Feeder

- FEEDER : total lenght 1320 mm

- 8 Infeed conveyors with 30 mm belts, with 4 built-in mechanical vibrators

- 1 Thickness gauge. With lateral and longitudinal adjustment and upper introduction rollers

- 1 Additional thickness gauge. With lateral and longitudinal adjustment and upper introduction rollers

- 2 Side lays in two parts. With right gauge equipped with a digital position indicator. Asymmetrical and adjustable longitudinally. Maximum height of the stack of die cut: 350 mm

- 1 Gear-motor. Controlled by a frequency converter for feeding the infeed belts and switching on or off

- 1 Series of adjustable rear guides mounted on a longitudinally adjustable carriage with pneumatic closure

- 1 Lower right transporter. With 25 mm belts and 1 obliquely adjustable upper transport for perfect alignment of the die cuts

- 1 Left Pre breaker positioned at 90°

- Pre Breaker

- Total lenght 2.300 mm

- Lower left conveyor with 43 mm belt. With digital position indicator

- 1 Lower right transporter. With 25 mm belts. With digital position indicator

- 1 Set of upper conveyors with 25mm belts and lifting device

- 1 Left pre-break without belt with built-in presser. Adjustable by eccentric. Max. width of the gluing flap: 30 mm

- 1 Reopening Guide

- 1 Right pre-break with 30 mm strap. Includes a system to adjust the pre-break angle

- 1 lower support guide

- Automatic Bottom

- Total width 1500 mm

- Lower conveyors with 25 mm belts. With digital position indicator

- Upper conveyors with longitudinal adjustment with 25 mm belt

- Lower support guides

- Set of hooks, bending propellers and guides

- Gluer System

- No. 1 bottom glue system on the left with disk and double scraper. With digital position indicator

- 1 Removable glue tank

- 1 Pressure guide with pressure roller

- 1 Filling bottle

- Folder system

- Total length 3000 mm

- 2 Lower conveyors with 25 mm belts. With digital position indicator

- 1 Set of longitudinally adjustable upper conveyors with 25 mm belts and lifting device

- 2 Folding equipment with 10/15/30 mm belts

- 2 Pressure rollers adjustable by eccentrics

- 2 speed variators for the folding belts

- 2 Integrated devices for lifting the folding belts on the left and right. For folding boxes with protruding flaps

- 1 Lower support guide

- Transfer system

- Total lenght 1400 mm

- 2 Lower conveyors with longitudinal adjustment with 25 mm belt. With digital position indicator

- 2 Upper conveyors with longitudinal manual adjustment with 25 mm belt

- 1 System for vertical adjustment of the lower and upper conveyor output. With automatic belt tensioning system

- 1 Flexible contact safety sensor

- Delivery

- Total length 4425 mm.

- Pressure length 2700 mm.

- 1 Independent exit with belt, width 900 mm.

- 1 Pneumatic pressure system adjustable by spindles. 2 independent adjustment zones

- 1 Automatic lateral correction guide system for the lower and upper belts

- 1 Scale regulator. For automatic stop of the exit in the event of interruption of the case arrival

- 1 Command for temporary acceleration of the exit

- 1 Command for independent start-up of the exit when the machine is stopped

- 1 Gearmotor controlled by a frequency converter. Speed regulation according to the space between the dies, to maintain a regular scale pitch

- Various

- B-5 PRE-BREAKING OR BENDING DEVICE

- B-13 ADDITIONAL TOOLS FOR REINFORCED CRASH-LOCK BOTTOM

- EA-6 MAIN GAUGE WITH LATERAL AND LONGITUDINAL ADJUSTMENT

- EA-8 CALIBER BLADE WITH BLOWER

- EA-15 ELECTRIC PILE VIBRATOR for the rear stack guides. It favors the introduction of blanks adhering to each other

- EA-80 LEFT ALIGNMENT CONVEYOR

- FA-001 LOWER CENTRAL CONVEYOR. With 25mm belts. It ensures and facilitates the transport of disproportionate or large format boxes

- F-5 UPPER CENTRAL CONVEYOR.With 25 mm belts. It ensures and facilitates the transport of disproportionate or large format boxes

- G-15 CENTRAL CONVEYORS. With digital position indicator. Central lower and upper conveyors with 25 mm belts. They ensure good central support for disproportionate or large format boxes

- HB-6 MOTORIZATION OF CONVEYORS. Motorized longitudinal adjustment of the left and right lower transport arms

- J-1 LEFT AND RIGHT INTRODUCER. 30 mm belt introducer. To precisely control the formation of the scale

- J-10 UPPER PRESSURE BELT. This accessory is essential for self-locking bottom and double-wall boxes. To exert additional pressure on a specific point on the box

- J-15 MIRROR. For visual monitoring of the introduction of boxes at the delivery

- J-025 LEFT AND RIGHT INTRODUCER AND RECTIFIER (necessity of: J-001) . To ensure good squaring of the corrugated cardboard self-bottom box. It is composed of corrector pegs operated by pneumatic mandrels

- K-3 KURANDT CODE READER COMPACT SERIES. Reading and checking the code printed on the gluing flap and checking the colours. It is composed of a control box and a reading head

- K-5 KURANDT LOWER GLUE TRACE DETECTOR COMPACT SERIES. Allows you to check the presence and regularity of the trace of glue in the gluing flap

- K-10 BOBST ROTARY EJECTOR with box advancement device. For the extraction of classic small and medium format boxes that do not comply with specifications

- K-15 GLUE LEVEL CONTROL DEVICE. It ensures a constant glue level in the lower left gluer tray. composed of a probe and an automatic tray filling system

- Close and flat box minimum 60 mm.

Machine overview

| Year | 2005 |

|---|---|

| Serial Number | 035603901 |

“EXTRA” Accessories Overview

- B-5 PRE-BREAKING OR BENDING DEVICE

- B-13 ADDITIONAL TOOLS FOR REINFORCED CRASH-LOCK BOTTOM

- EA-6 MAIN GAUGE WITH LATERAL AND LONGITUDINAL ADJUSTMENT

- EA-8 CALIBER BLADE WITH BLOWER

- EA-15 ELECTRIC PILE VIBRATOR for the rear stack guides. It favors the introduction of blanks adhering to each other

- EA-80 LEFT ALIGNMENT CONVEYOR

- FA-001 LOWER CENTRAL CONVEYOR. With 25mm belts. It ensures and facilitates the transport of disproportionate or large format boxes

- F-5 UPPER CENTRAL CONVEYOR.With 25 mm belts. It ensures and facilitates the transport of disproportionate or large format boxes

- G-15 CENTRAL CONVEYORS. With digital position indicator. Central lower and upper conveyors with 25 mm belts. They ensure good central support for disproportionate or large format boxes

- HB-6 MOTORIZATION OF CONVEYORS. Motorized longitudinal adjustment of the left and right lower transport arms

- J-1 LEFT AND RIGHT INTRODUCER. 30 mm belt introducer. To precisely control the formation of the scale

- J-10 UPPER PRESSURE BELT. This accessory is essential for self-locking bottom and double-wall boxes. To exert additional pressure on a specific point on the box

- J-15 MIRROR. For visual monitoring of the introduction of boxes at the delivery

- J-025 LEFT AND RIGHT INTRODUCER AND RECTIFIER (necessity of: J-001) . To ensure good squaring of the corrugated cardboard self-bottom box. It is composed of corrector pegs operated by pneumatic mandrels

- K-3 KURANDT CODE READER COMPACT SERIES. Reading and checking the code printed on the gluing flap and checking the colours. It is composed of a control box and a reading head

- K-5 KURANDT LOWER GLUE TRACE DETECTOR COMPACT SERIES. Allows you to check the presence and regularity of the trace of glue in the gluing flap

- K-10 BOBST ROTARY EJECTOR with box advancement device. For the extraction of classic small and medium format boxes that do not comply with specifications

- K-15 GLUE LEVEL CONTROL DEVICE. It ensures a constant glue level in the lower left gluer tray. composed of a probe and an automatic tray filling system

Reference Overview

| Reference | 24036430 |

|---|---|

| Visible | Sbm Rebuilding Center of Robecco sul Naviglio (MI) |

| Availability | Immediately |

Contacts

Camporese Macchine Grafiche S.p.A

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Via Del Santo, 243 - 35010 - Limena (Padova) Italy

+39 049 767166

+39 049 767629

info@camporese.it

Partita Iva IT03429400280

Euro 2.000.000,00 issued and fully paid-up share capital

Euro 5.495.000,00 net asset